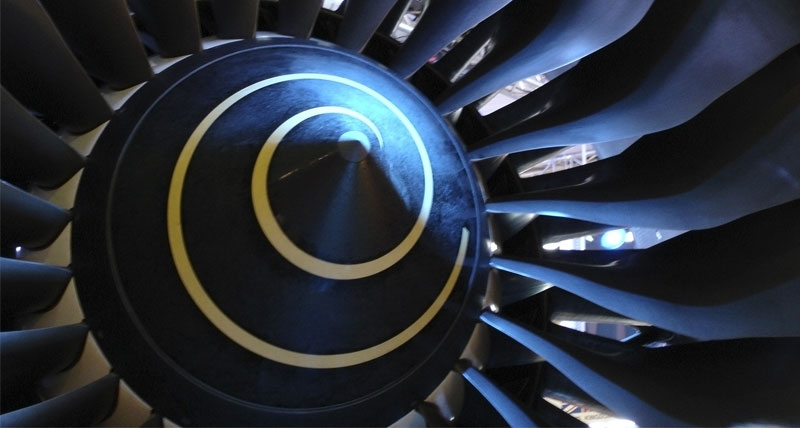

Reverse engineering of aircraft components for MRO

Part scanning to reverse engineer older aircraft components for maintenance, repair and overhaul operations

Contact us

Aircraft maintenance, repair and overhaul (MRO) operations rely on timely access to a supply of spare parts to make repairs possible and ensure airlines have their fleets in the air and not in the MRO hangar.

In the case of newer aircraft, MRO teams usually have access to replacement parts or hold a CAD model for the part they need. But in the case of older aircraft, spares can be difficult to obtain and original CAD files may not be available either, making reverse engineering the only option to source the required parts. Reverse engineering is also a good option for replacing parts that have a long lead-time or do not play a critical role.

In these instances, MRO engineers need to create a CAD model before they can manufacture the replacement part. Hexagon’s 3D optical and laser scanning solutions capture rich, point-cloud data ideal for reverse engineering, enabling aircraft MRO teams to construct the replacement parts they need to perform their own repairs and reduce aircraft downtime.

In the case of newer aircraft, MRO teams usually have access to replacement parts or hold a CAD model for the part they need. But in the case of older aircraft, spares can be difficult to obtain and original CAD files may not be available either, making reverse engineering the only option to source the required parts. Reverse engineering is also a good option for replacing parts that have a long lead-time or do not play a critical role.

In these instances, MRO engineers need to create a CAD model before they can manufacture the replacement part. Hexagon’s 3D optical and laser scanning solutions capture rich, point-cloud data ideal for reverse engineering, enabling aircraft MRO teams to construct the replacement parts they need to perform their own repairs and reduce aircraft downtime.

Our solutions

Explore Hexagon solutions for reverse engineering aircraft partsAutomated 3D Scanning

The SmartScan 3D optical scanner quickly captures detailed data and is designed for use in challenging environments.

Portable 3D Scanning

The Absolute Arm with integrated RS5 Laser Scanner delivers high-resolution 3D scanning for surfaces and hidden points features whatever the finish or material.