Q-DAS O-QIS

The SPC Software O-QIS records and evaluates measurement values from different measurement systems (e.g. CMM)

The tool for classical statistical process control (SPC)

O-QIS provides essential features fully supporting users in their quality assessment tasks.

Ready to learn more?

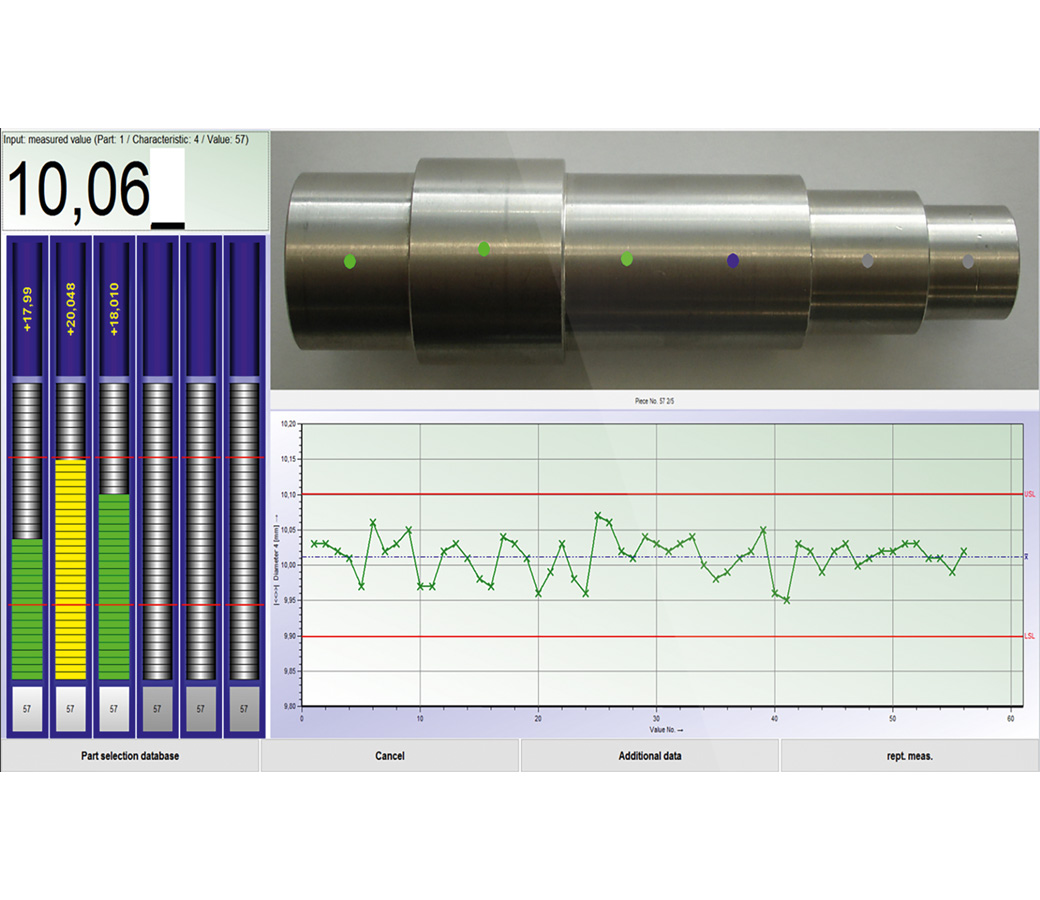

Real-time visualisation

Q-DAS O-QIS is used to display and evaluate inspection and process data. There are several different ways of generating these data. For that reason, Q-DAS O-QIS has various modules to offer the right solution for the task at hand and is also available as a web-based product.Product capabilities

SPC for process documentation

There are different ways to record measurement and test data and to transfer them to O-QIS. Besides manual input of data, the software is also able to transfer data directly from portable measuring equipment, multipoint measuring instruments, measuring devices and multiplexers via RS232 or USB interface. Appealing charts (e.g. quality control chart, value chart, bar chart, etc.) visualise the recorded measured values and help users to evaluate them for the respective purpose.

The software’s high flexibility allows users to adapt the recording and visualisation of data to specific tasks. Users can adjust the software according to their requirements – from a configuration that is easy to use to any individually defined measurement process control.

Online alarm monitoring creates transparency

Recording a mass of data in a short time, as is the case with process parameters from assembly systems, injection moulding machines or furnaces, requires real-time visualisation and alarm monitoring.

Whether you need to show individuals, trend charts of measured values or a compact status indication of each production facility, O-QIS® offers the graphics and tables you need. The software transfers the data collected by the measurement system in the Q-DAS ASCII transfer format.

Real-time visualisation for smart decisions

The visualisation of measurements including many characteristics and long measurement cycles, e.g. measurements from coordinate measuring machines or complex measuring devices, focuses on characteristics causing problems; the software highlights them. This approach makes it easy to identify the weak points of a process.

A well-structured graphical user interface with simple buttons wins high acceptance among users.

Alert function raises confidence

In order to minimise the risk of overlooking deviations from target specifications, O-QIS immediately checks whether measured values meet individual alarm conditions. There are different ways to inform selected users of an alarm that has occurred. The software shows the characteristics causing the alarm and is also able to generate and send reports automatically (printout, PDF, E-Mail or SMS).Extensions:

-

Form Designer

-

Q-DM Datamanagement

-

SAP QM-STI interface