OPTIV M DualScan+

The cycle-time improvement solution for complex 3D components

Would you like to know more?

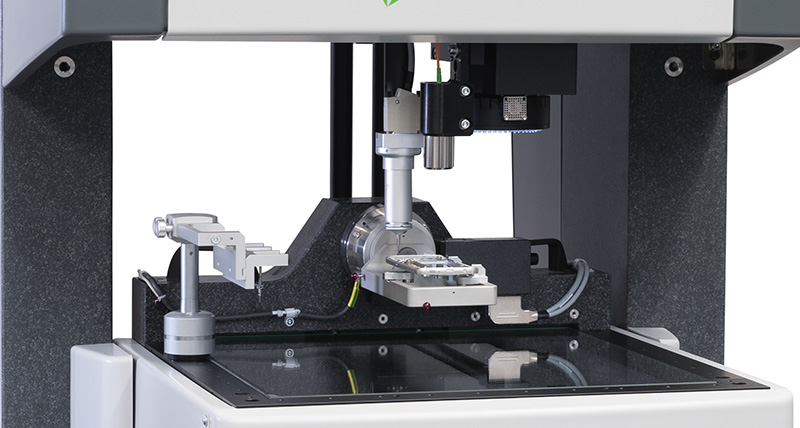

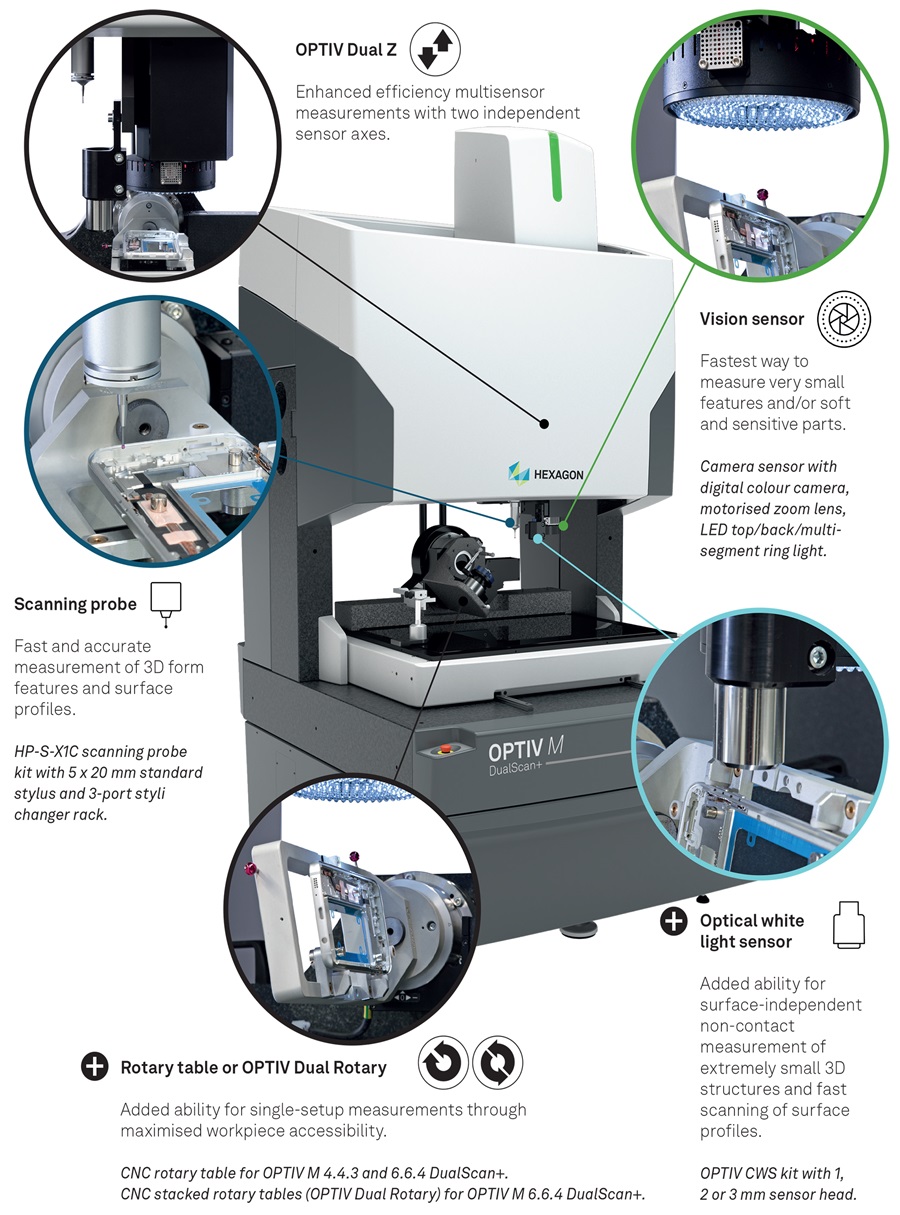

OPTIV M DualScan+ reduces the time needed for the complete multisensor measurement of complex precision parts by combining a unique array of sensors with advanced flexibility in feature accessibility.

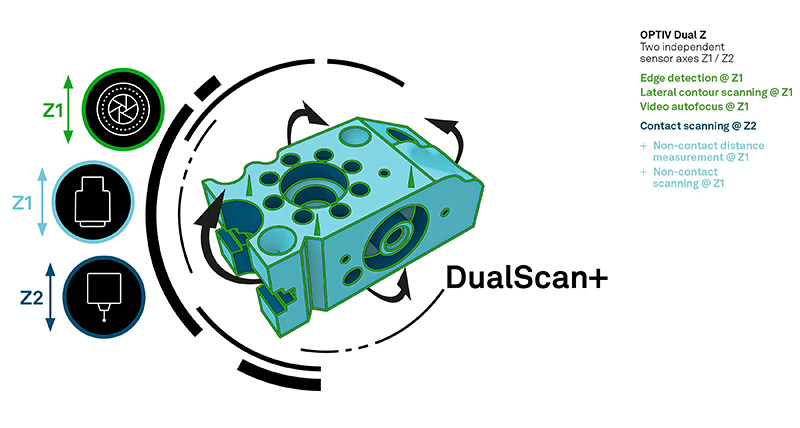

- All-in-one metrology solution with two independent sensor axes (OPTIV Dual Z) – camera sensor + scanning probe + optical white light sensor + CNC rotary table or CNC stacked rotary tables provide advanced flexibility in part accessibility, minimising setup time, inspection time and risk of collision

- Future-ready modularity allows for easy in-field upgrade of the base system

- ISO 10360 compliant 3D measurement performance with high accuracy – optical and tactile

- Effortless smart manufacturing integration of OPTIV M DualScan+ due to standardised automation interface and seamless integration with Hexagon’s IoT technologies for remote asset and environment monitoring

- Intuitive operability of OPTIV M DualScan+ through a simplified operator interface

- Future-proof investment fully backed up by Hexagon’s global service and support network

-

Downloads

Complex dual-axis sensor measurement

Discover the typical applications suited to complex dual-axis sensor systems.