Quality assurance of turbine blades

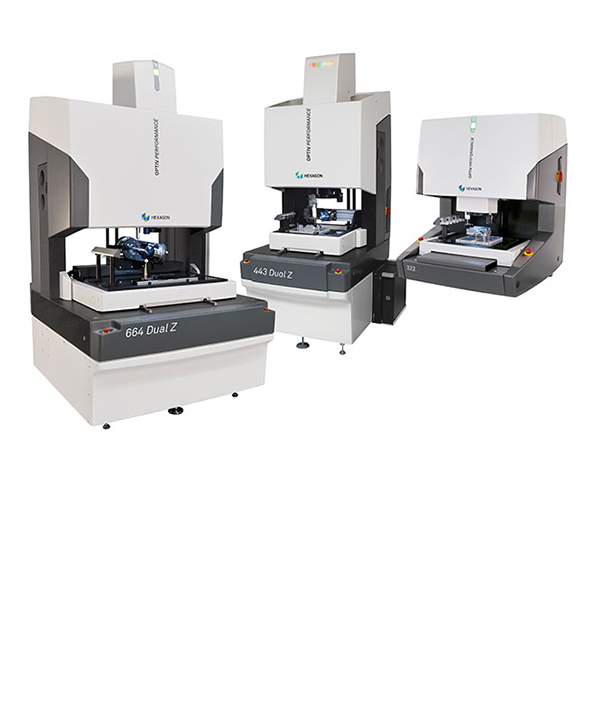

Multisensor technology, Optiv Dual Z and Optiv Dual Rotary increase measurement throughput.

Contact us

The functional properties of turbine blades are multifaceted. A curved surface gives them aerodynamic properties, and specially shaped cooling holes ensure their thermal stability.

With its multisensor concept, the Optiv Performance 663/664 Dual Z coordinate measuring machine from Hexagon Manufacturing Intelligence integrates multiple measurement processes in a single machine and, thanks to the optional Optiv Dual Z and Optiv Dual Rotary options, features innovative technologies that ensure accessibility to a variety of different features in the overall measurement volume and their measurement in a single clamping.

image-processing algorithm that enables calculation of the centre point of the hole based on a centre-of-area calculation.

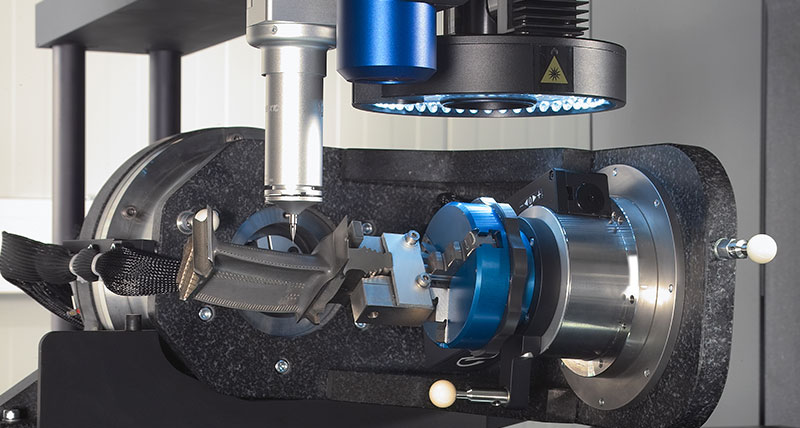

Using the Optiv Dual Rotary stacked rotary tables, the axis of the hole to be tested is aligned parallel to the sensor axis of the coordinate measuring machine. The shape and position of the hole are then determined through probing with the HP-S-X1 tactile sensor (ball-tip diameter in example: 130 μm) at defined depths.

The Optiv Performance 663/664 Dual Z coordinate measuring machine from Hexagon Manufacturing Intelligence represents a comprehensive metrological concept enabling the complete testing of the highly-complex geometry of turbine blades in a single setup.

With its multisensor concept, the Optiv Performance 663/664 Dual Z coordinate measuring machine from Hexagon Manufacturing Intelligence integrates multiple measurement processes in a single machine and, thanks to the optional Optiv Dual Z and Optiv Dual Rotary options, features innovative technologies that ensure accessibility to a variety of different features in the overall measurement volume and their measurement in a single clamping.

Alignment with the HP-S-X1 tactile sensor

The coordinate alignment of the turbine blade occurs at its base, where corresponding control geometry elements are found. The required measurement points are recorded with the HP-S-X1 tactile sensor.Multisensor measurement of the cooling holes

First, the position and size of the hole are measured with the vision sensor. Its high-resolution camera and low-distortion precision optics guarantee maximum optical precision. A particular challenge is that cooling holes created with a laser or erosion process exhibit an irregular shape. For functional reasons, they are often created at an angle to the surface or lie in a heavily-curved section of the turbine blade. This causes the cooling holes to appear oval in shape during the optical measurement. The solution provided by the PC-DMIS CAD++ measurement software is a specialisedimage-processing algorithm that enables calculation of the centre point of the hole based on a centre-of-area calculation.

Using the Optiv Dual Rotary stacked rotary tables, the axis of the hole to be tested is aligned parallel to the sensor axis of the coordinate measuring machine. The shape and position of the hole are then determined through probing with the HP-S-X1 tactile sensor (ball-tip diameter in example: 130 μm) at defined depths.

Surface scan with the chromatic white-light sensor (CWS)

The functionally relevant freeform surfaces of the turbine blade are digitalised using profile scans with the CWS in the same clamping. This contactless point sensor enables fast and surface-independent 3D scans with a high point density. The surface data obtained is evaluated against the imported CAD data set in the PC-DMIS CAD++ measurement software.The Optiv Performance 663/664 Dual Z coordinate measuring machine from Hexagon Manufacturing Intelligence represents a comprehensive metrological concept enabling the complete testing of the highly-complex geometry of turbine blades in a single setup.