Fully automated robotic cell for integrated quality measurement

Isolit-Bravo - Czech Republic

Contact us

Isolit-Bravo was founded in 1921 at Jablonné nad Orlicí near the Polish border as the first Bakelite mill in Bohemia. After the 1960s, the rising popularity of plastic forced the company to transform itself, changing its production, buying new machines, and beginning to mould plastic parts. This transformation laid the foundations for a successful Czech company. Today Isolit-Bravo employs nearly 500 people and remains a traditional, solely Czech-owned company, recognised as a key supplier of quality products for world-renowned companies.

Customers are mainly in the automotive industry and include Volkswagen, Skoda, BMW, Bentley, Jaguar and Audi, followed by the electrical engineering and household appliance segments. In addition, Isolit-Bravo produces its own household appliances under the Bravo and Motúčko brands.

Customers are mainly in the automotive industry and include Volkswagen, Skoda, BMW, Bentley, Jaguar and Audi, followed by the electrical engineering and household appliance segments. In addition, Isolit-Bravo produces its own household appliances under the Bravo and Motúčko brands.

Combined with a professional approach toward customer support, Hexagon’s offering was seen by us to be the best solution covering the needs of Isolit-Bravo. Our belief in having made the right choice is backed by more than a year of error-free practice and positive feedback from our customers.

Luboš Bárta

Automation application engineer

Although plastic moulding is Isolit-Bravo’s principal activity, an integral part of the plant is the tool shop, where the company designs, develops and manufactures instruments, injection moulds and dies ranging in size from a few kilograms to several tonnes, both for their own needs and for those of customers all over Europe. Moulds can be designed and customised in the desired shape for customers and cast with special software programs for simulating and optimising injection moulding. Besides moulds and tools to manufacture plastics, sheet metal processing instruments such as progressive cutting dies and deep drawing presses are also produced.

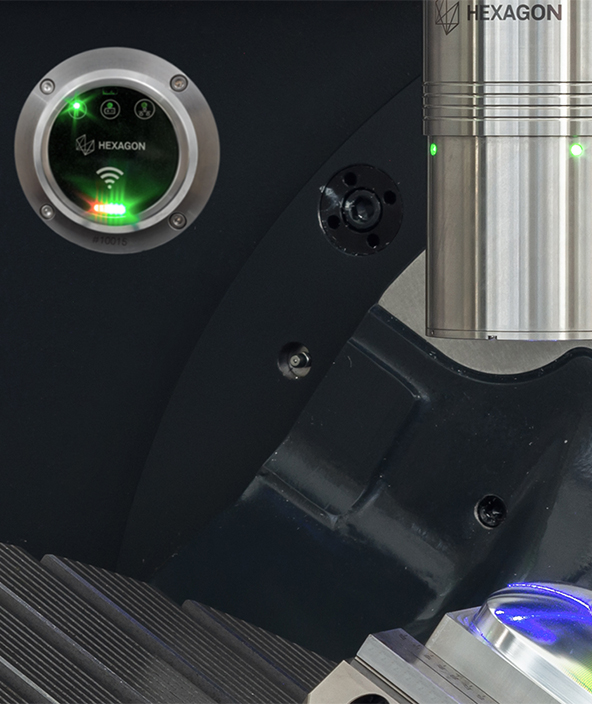

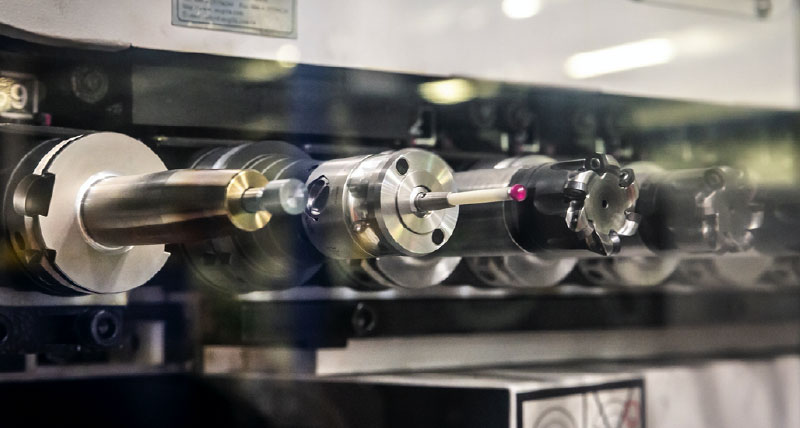

Isolit-Bravo’s first contact with Hexagon Manufacturing Intelligence came in 2013 when the company purchased a range of Hexagon’s m&h machine tool probes for its milling machines and detecting tool geometry at its machining centres. Another relationship with Hexagon developed four years later when Isolit-Bravo began to consider increasing its automation levels.

Isolit-Bravo’s first contact with Hexagon Manufacturing Intelligence came in 2013 when the company purchased a range of Hexagon’s m&h machine tool probes for its milling machines and detecting tool geometry at its machining centres. Another relationship with Hexagon developed four years later when Isolit-Bravo began to consider increasing its automation levels.

This initiative was driven in part by a desire to increase efficiency and effectiveness and cut costs, but Isolit-Bravo felt there was a crucial issue to be tackled: a lack of experienced manpower in the local region that could oversee its production.

Isolit-Bravo opted to implement an automated robotic cell in production for piece work manufacturing. The robotic cell was installed by GF Machining Solutions s.r.o., which chose Hexagon Manufacturing Intelligence as the best technology subcontractor solution for quality control of measurement. “One of the main reasons we opted for Hexagon’s comprehensive solutions is for the reliability and integrity of the interconnection between all the supplied products,” explains Luboš Bárta, an automation application engineer at GF Machining Solutions.

The cell is based on a six-axis linear robot positioned on rails to move objects between different work stations and four CNC machines. There are three five-axis milling machines producing both steel parts for moulds, graphite electrodes for the manufacture of stamped parts and an EDM drilling machine.

For Isolit-Bravo, the automated cell profoundly reduces errors, required manpower, and the total time for manufacturing operations. Partly this is due to automated improvements, as the GLOBAL Shop Floor CMM measures every detail and the data is continuously shared with the line’s management software, continually processing and, where necessary, adjusting the machining of parts. In conjunction with PC-DMIS EDM Preset & Measure, the GLOBAL Shop Floor CMM safely, quickly and easily determines the positioning of workpieces or electrodes relative to the clamping system (XYZC) and shares this data with other machines in the automated robotic cell. Because the software has a customisable library of ready-to-use macros, operators only need minimal programming knowledge.

For Isolit-Bravo, the automated cell profoundly reduces errors, required manpower, and the total time for manufacturing operations. Partly this is due to automated improvements, as the GLOBAL Shop Floor CMM measures every detail and the data is continuously shared with the line’s management software, continually processing and, where necessary, adjusting the machining of parts. In conjunction with PC-DMIS EDM Preset & Measure, the GLOBAL Shop Floor CMM safely, quickly and easily determines the positioning of workpieces or electrodes relative to the clamping system (XYZC) and shares this data with other machines in the automated robotic cell. Because the software has a customisable library of ready-to-use macros, operators only need minimal programming knowledge.

One year after installation, Isolit-Bravo has found its manufacturing process to be more efficient and simple. An engineer creates a CAD model and drawings and a machining program, plus the measurement routine in PC-DMIS, which is operated by Isolit-Bravo under network licences. The finished programs are uploaded onto the corporate server, then operators assign them to specific productions. An operator puts material in the container and attaches the RF chip that identifies it. A robot then picks up the material from the container and moves it to the CMM for positioning (preset of XYZC). This information is then transferred and used in the EDM milling machine; this step is done once in the beginning and then setup is used in all machines in the robotic cell, saving time and avoiding manual entry. When the workpiece is done it is automatically transferred by robot to the washing machine, where it is thoroughly cleaned to ensure the highest possible measurement precision.

All in all, Isolit-Bravo has estimated the time saved each month to equal seven full-time employees, who were moved to other projects. GF Machining Solutions Luboš Bárta says: “Combined with a professional approach toward customer support, Hexagon’s offering was seen by us to be the best solution covering the needs of Isolit-Bravo. Our belief in having made the right choice is backed by more than a year of error-free practice and positive feedback from our customers.”

Looking ahead, Isolit-Bravo has decided to enhance the current solution by installing another milling machine to increase production capacity.

Isolit-Bravo’s first contact with Hexagon Manufacturing Intelligence came in 2013 when the company purchased a range of Hexagon’s m&h machine tool probes for its milling machines and detecting tool geometry at its machining centres. Another relationship with Hexagon developed four years later when Isolit-Bravo began to consider increasing its automation levels.

Isolit-Bravo’s first contact with Hexagon Manufacturing Intelligence came in 2013 when the company purchased a range of Hexagon’s m&h machine tool probes for its milling machines and detecting tool geometry at its machining centres. Another relationship with Hexagon developed four years later when Isolit-Bravo began to consider increasing its automation levels.This initiative was driven in part by a desire to increase efficiency and effectiveness and cut costs, but Isolit-Bravo felt there was a crucial issue to be tackled: a lack of experienced manpower in the local region that could oversee its production.

Isolit-Bravo opted to implement an automated robotic cell in production for piece work manufacturing. The robotic cell was installed by GF Machining Solutions s.r.o., which chose Hexagon Manufacturing Intelligence as the best technology subcontractor solution for quality control of measurement. “One of the main reasons we opted for Hexagon’s comprehensive solutions is for the reliability and integrity of the interconnection between all the supplied products,” explains Luboš Bárta, an automation application engineer at GF Machining Solutions.

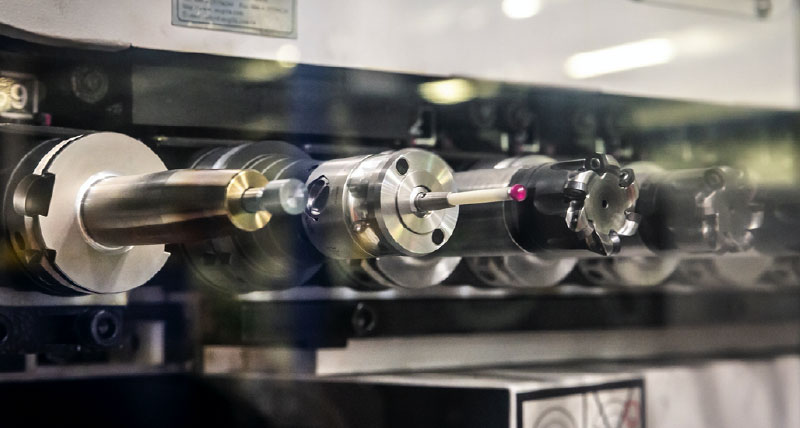

The cell is based on a six-axis linear robot positioned on rails to move objects between different work stations and four CNC machines. There are three five-axis milling machines producing both steel parts for moulds, graphite electrodes for the manufacture of stamped parts and an EDM drilling machine.

Other parts of this comprehensive, fully automated solution are a washing machine, adapters for several different clamping systems, containers and a range of products from Hexagon’s portfolio: a GLOBAL Shop Floor coordinate measuring machine (CMM), PC-DMIS EDM Preset & Measure software and Vero WorkNC CAD/CAM software for two to five-axis machining.

Automation and integrity for greater efficiency

For Isolit-Bravo, the automated cell profoundly reduces errors, required manpower, and the total time for manufacturing operations. Partly this is due to automated improvements, as the GLOBAL Shop Floor CMM measures every detail and the data is continuously shared with the line’s management software, continually processing and, where necessary, adjusting the machining of parts. In conjunction with PC-DMIS EDM Preset & Measure, the GLOBAL Shop Floor CMM safely, quickly and easily determines the positioning of workpieces or electrodes relative to the clamping system (XYZC) and shares this data with other machines in the automated robotic cell. Because the software has a customisable library of ready-to-use macros, operators only need minimal programming knowledge.

For Isolit-Bravo, the automated cell profoundly reduces errors, required manpower, and the total time for manufacturing operations. Partly this is due to automated improvements, as the GLOBAL Shop Floor CMM measures every detail and the data is continuously shared with the line’s management software, continually processing and, where necessary, adjusting the machining of parts. In conjunction with PC-DMIS EDM Preset & Measure, the GLOBAL Shop Floor CMM safely, quickly and easily determines the positioning of workpieces or electrodes relative to the clamping system (XYZC) and shares this data with other machines in the automated robotic cell. Because the software has a customisable library of ready-to-use macros, operators only need minimal programming knowledge.One year after installation, Isolit-Bravo has found its manufacturing process to be more efficient and simple. An engineer creates a CAD model and drawings and a machining program, plus the measurement routine in PC-DMIS, which is operated by Isolit-Bravo under network licences. The finished programs are uploaded onto the corporate server, then operators assign them to specific productions. An operator puts material in the container and attaches the RF chip that identifies it. A robot then picks up the material from the container and moves it to the CMM for positioning (preset of XYZC). This information is then transferred and used in the EDM milling machine; this step is done once in the beginning and then setup is used in all machines in the robotic cell, saving time and avoiding manual entry. When the workpiece is done it is automatically transferred by robot to the washing machine, where it is thoroughly cleaned to ensure the highest possible measurement precision.

All in all, Isolit-Bravo has estimated the time saved each month to equal seven full-time employees, who were moved to other projects. GF Machining Solutions Luboš Bárta says: “Combined with a professional approach toward customer support, Hexagon’s offering was seen by us to be the best solution covering the needs of Isolit-Bravo. Our belief in having made the right choice is backed by more than a year of error-free practice and positive feedback from our customers.”

Looking ahead, Isolit-Bravo has decided to enhance the current solution by installing another milling machine to increase production capacity.