Q-DAS solara.MP

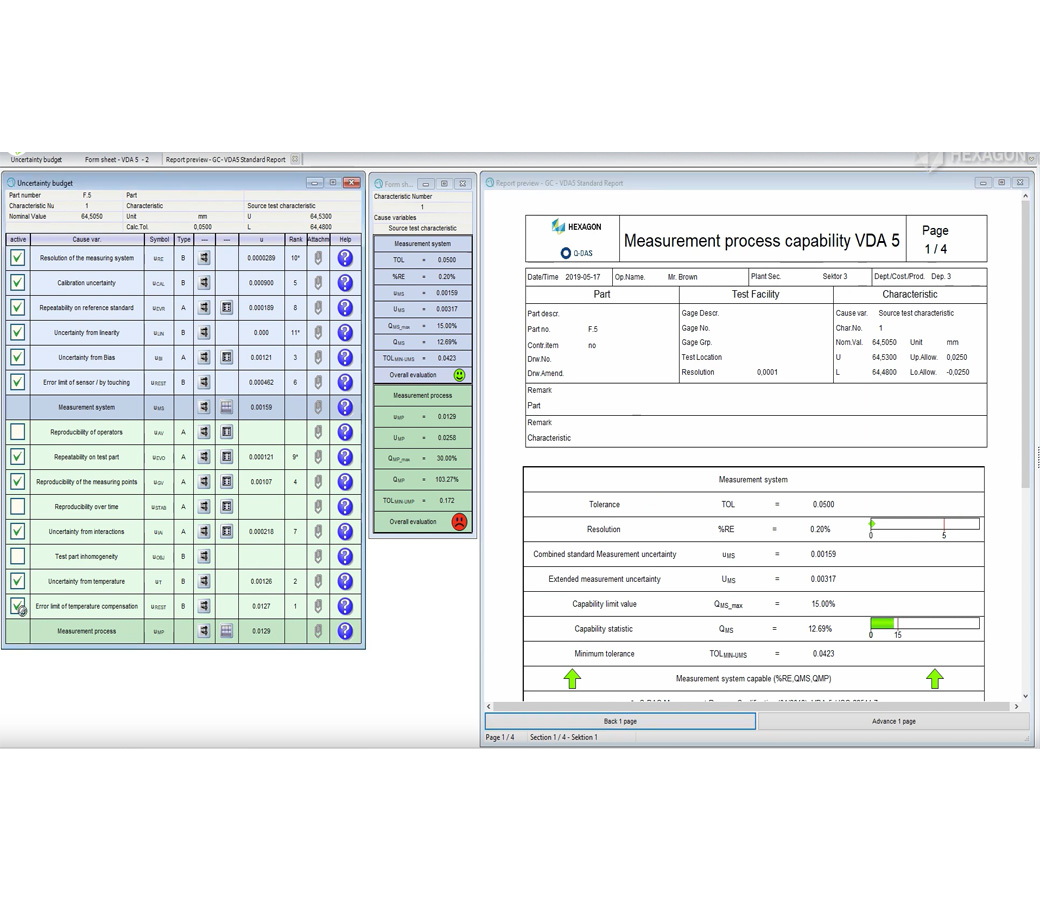

Solara checks measurement equipment and measurement processes. MSA and VDA 5 studies, as well as attributive MSA are carried out.

The most reliable and actionable information you need

solara.MP is the perfect choice to establish measurement process capability.

Ready to learn more?

Inspection process suitability

Misinterpretations of process data can be avoided by making sure that the measurement values obtained reflect the actual situation at hand with sufficient certainty, i.e. the measurement processes must be suitable for the application case at hand. These proofs of suitability can be created with Q-DAS solara.MP – also available as a web-based product.Product capabilities

Evaluation of machines

The evaluation of machines, production facilities and current manufacturing processes is based on the statistical analysis of characteristic values. Processes measuring predefined characteristics provide these values. In order to avoid misinterpretations, the recorded measured values have to be reliable reflecting the real conditions, i.e. measurement processes have to be capable of performing the demanded task in the respective situation. solara.MP is the perfect choice to establish measurement process capability.

Measurement system capability according to MSA

Suitable measurement processes are required to achieve beneficial results. The MSA (Measurement Systems Analysis) reference manual often provides the basis for this decision. solara.MP is the tool of choice for instrument and gauge capability.

solara.MP conducts necessary capability studies to establish measurement system capability. The main differences between generally accepted studies such as type-1 (Cg/Cgk), type-2 and type-3 studies (%GRR) or linearity and stability analyses are the applied calculation methods and the respective limit values. The software encompasses the procedures given in the MSA manual of the AIAG Core Tools and many other guidelines of the automotive industry.

Capability analysis according to VDA 5

Measurement processes are affected by a variety of influence quantities. Many standards thus demand the calculation of measurement uncertainty. VDA Volume 5 offers a practical approach and solara.MP helps to implement it easily and intuitively.

The calculation of measurement uncertainty is based on an approach that is quite as pragmatical as a MSA capability analysis; however, it follows the specifications of GUM (Guide to the expression of uncertainty in measurement) or EN V 13005. solara.MP thus combines uncertainty components into an uncertainty budget and calculates the expanded measurement uncertainty U.

Quintessence

Regardless of the methods you use and whether you conduct capability analyses at a test station, production line or in a test laboratory, solara.MP makes sure to provide you with the most reliable and actionable information you need!

Standards for Quality Management concretely require a confirmation for the eligibility of the applied software for the intended application, before initial use as well as for continuous use.

Extensions:

-

Languages

-

Form Designer

-

Serial interfaces

-

Q-DM Datamanagement