ETALON ABSOLUTE MULTILINE TECHNOLOGY

Pioneering length measurement

Deformation analysis, geometry monitoring and absolute interferometry

Would you like to know more?

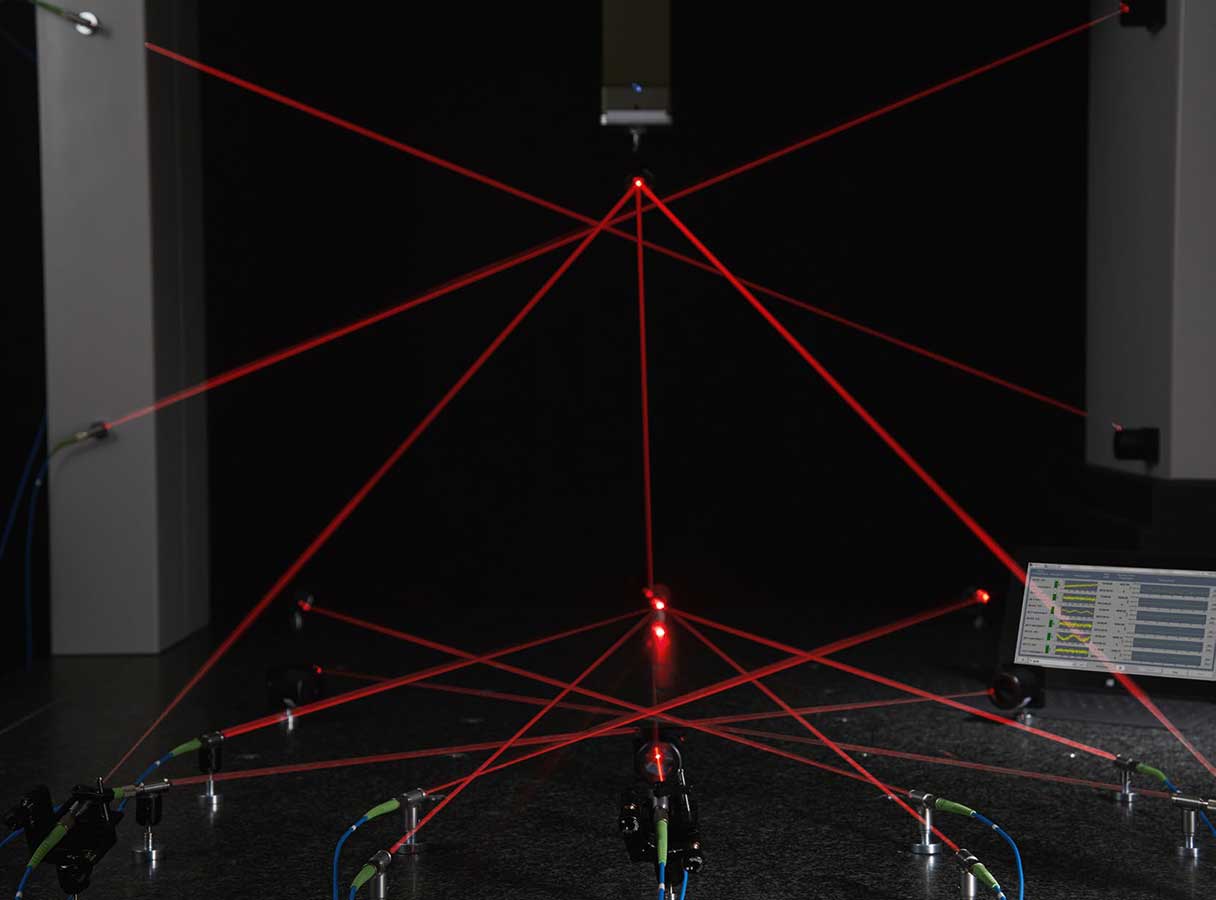

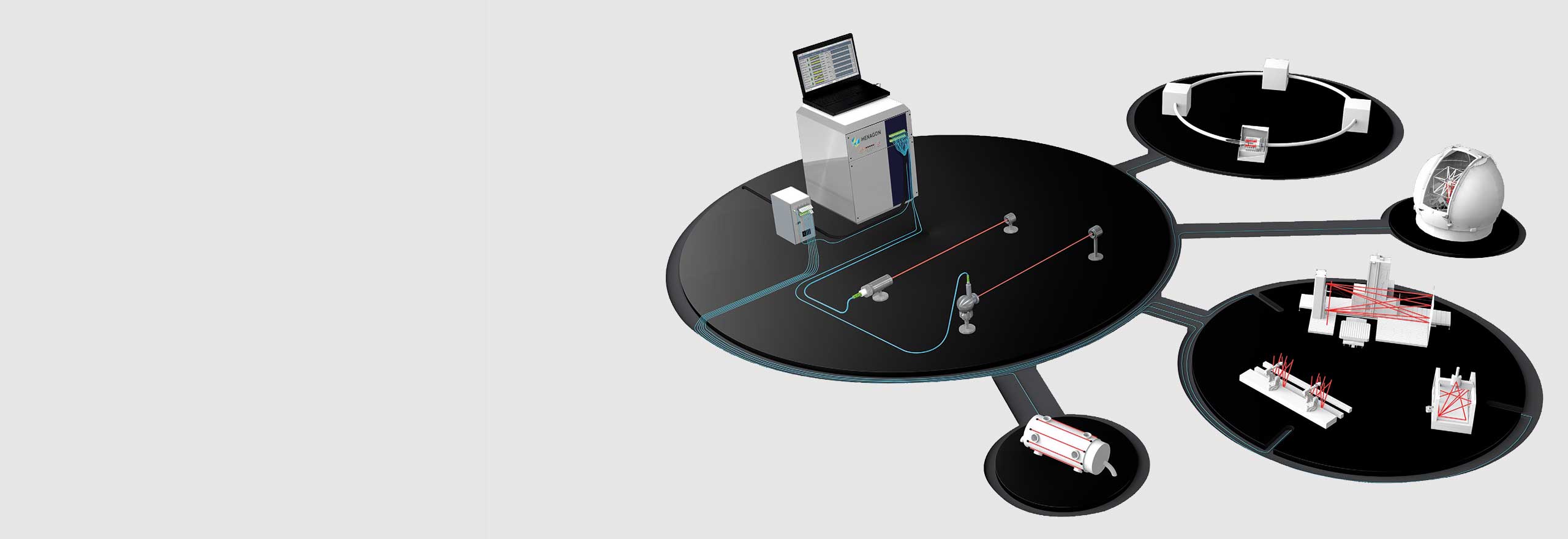

The system can precisely measure lengths up to 30 m, with an uncertainty of only 0.5 µm per metre. A single system can operate up to 124 measuring channels simultaneously.

Unlike conventional interferometers, the measuring beam can be interrupted at any time, and in a fraction of a second at the next measurement shot, the system again determines the absolute distance without any loss of accuracy, assuring the highest geometric precision.

Thanks to these unique system properties, this technology takes metrology automation in production to a new level.

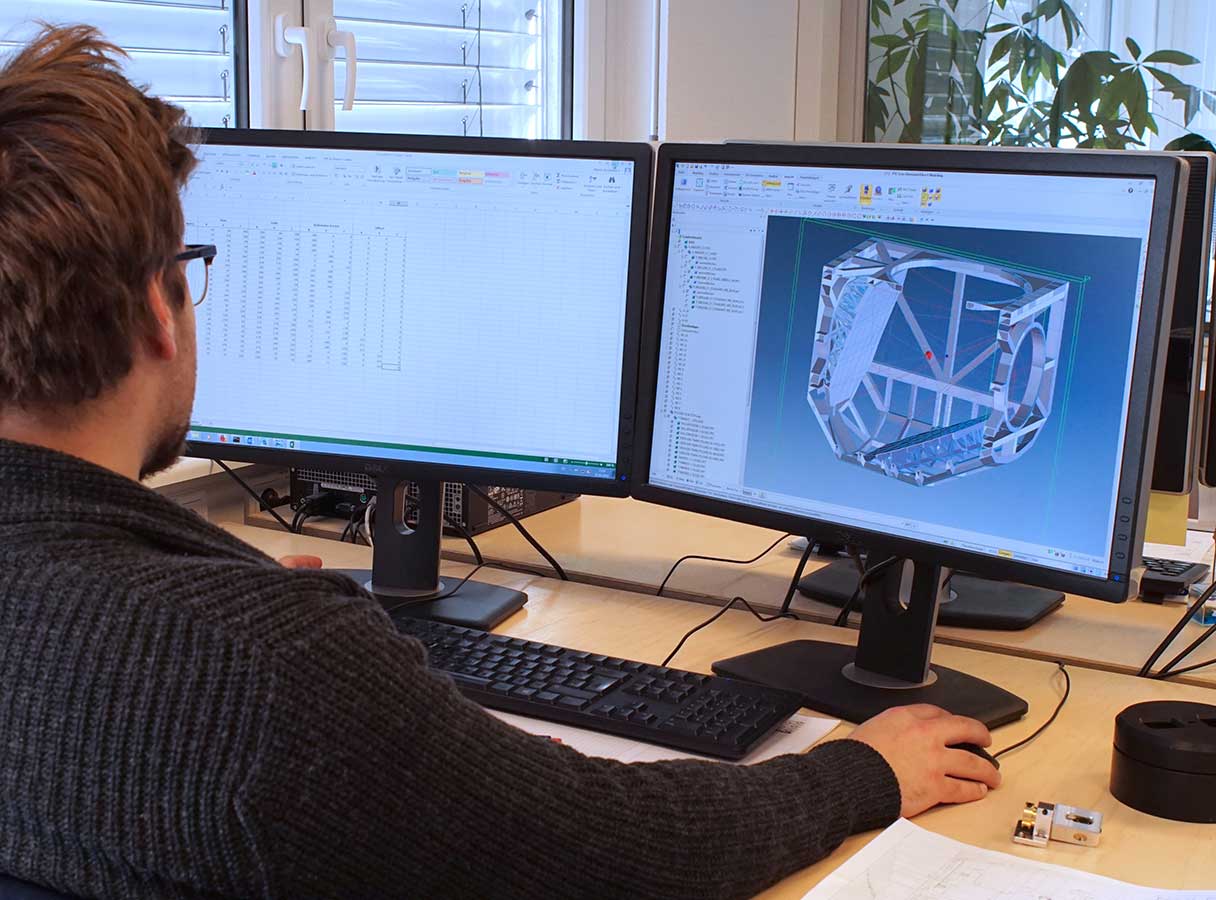

Research and development

- Position monitoring of mirrors and detectors of large telescopes to reduce set-up times and ensure sharper images

- Measurement and positioning of components in a vacuum at particle accelerators, such as CERN

- Analysis of the smallest deformations of machines and structures, e.g. for load and temperature tests

- Optical surface measurement of deformations and deviations from nominal geometries

Central metrology system, assembly and quality assurance

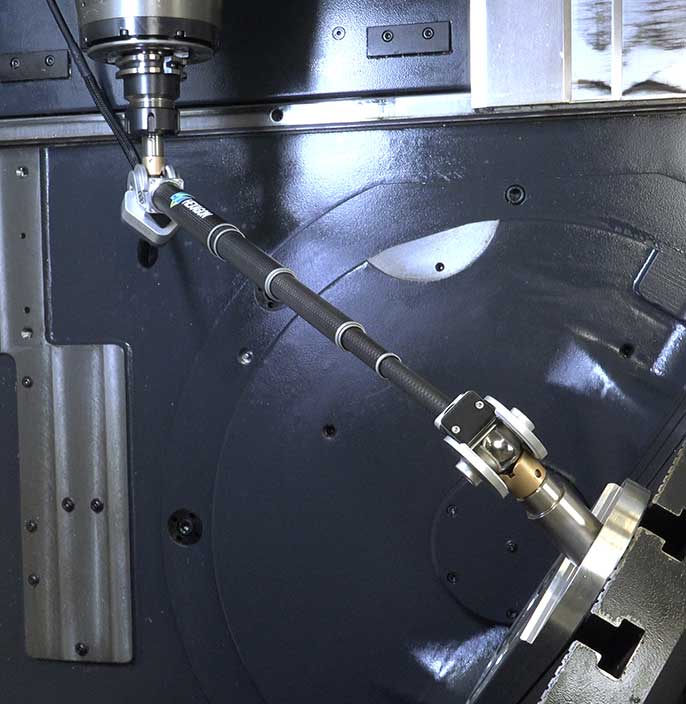

- Automated deformation and position measurements of large structures and components

- Factory-wide metrological network for the automated monitoring and compensation of the geometry of machine tools and measuring machines to ensure the dimensional accuracy of manufactured parts

- For national metrology institutes, the system serves as a length reference that can be transmitted over long distances to different buildings

Features and benefits

Absolute distance measurement from a few millimetres (close range configuration) up to 30 m (standard configuration) and more

Measurement uncertainty (95%) = 0.5 μm/m for distances between 0.02 m and 30 m.

Up to 124 synchronous channels allow for the set-up of complex metrological networks

Robust measurement sensors allow reliable operation in the harshest environments

Measuring fibres up to 7 km in length

Additional channels using sequential multiplexing via fibre switches

Suitable for factory-wide installation with central laser and evaluation unit

Comprehensive software for geometric monitoring in 1D and a server interface for third-party software is available

-

Technical data

-

Customer stories

-

Downloads