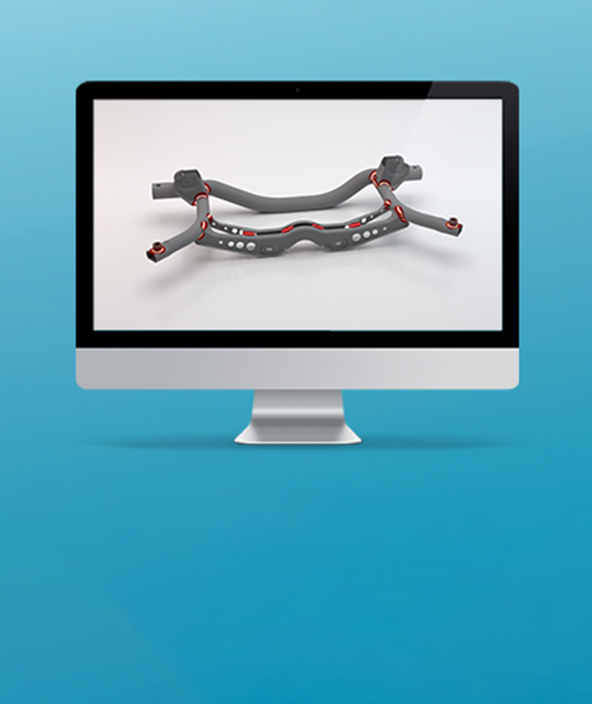

Hexagon Virtual Assembly

Evaluate and optimize the manufacturing process virtually to get to the right fit and function faster in reality.

Assembly Process Simulation Software

Simulate the assembly process to predict and mitigate distortion, improve process stability, and decrease cycle times.

Ready to get started?

Overcoming your manufacturing challenges with Hexagon Virtual Assembly

Manufacturing processes traditionally rely on physical prototypes for validation, which is both time-consuming and costly. Significant cost and time savings is possible by reducing or eliminating the prototype phase of the product development cycle.

Many factors contribute to the challenge:

- Mnufacturing process deforms parts and assemblies making it challenging to reach dimensional targets

- Difficult to select process and tooling to optimize for cycle time, cost, and dimensional while meeting program timing

- Unstable tool design can lead to low process capability / robustness

- Parts coming into the assembly process generally not CAD nominal

Our Solution: Hexagon Virtual Assembly

Hexagon Virtual Assembly enables virtualization of the assembly process through a variety of flexible software based workflows supporting auto, aero, electronics, and a host of other industry applications.

With Hexagon's Virtual Assembly:

- Predict how assemblies respond to the manufacturing process

- Reduce cycle time, tooling cost, and maintenance

- Optimize tooling to reduce the number of clamps and fixtures

- Consider the impact of non-nominal parts on the assembly process outcome

- Optimize assembly tooling and process for stability and robustness

The problem

Manufacturing processes distort parts and assemblies

What's possible...

- Predict how assemblies respond to the manufacturing process

With Virtual Assembly...

- Simulate to predict the impact of welding process

- Iterate on process and fixture design based on the simulation results

The problem

Assembly tooling is overly complex, based on tribal knowledge and prior programs

What's possible...

Optimize tooling to reduce the number of clamps

With Virtual Assembly...

- Locate tooling at ideal locations to achieve repeatability while reducing tool complexity / quantity

- Reduce station cycle time, cost of tooling, maintenance

The problem

Parts coming into the assembly process are not CAD nominal

What's possible...

Consider the impact of non-nominal parts on the assembly process outcome

With Virtual Assembly...

- Utilize scan data to morph CAD to match reality

- Include forming history from simulation

The problem

Poorly designed tools lead to process instability

What's possible...

Optimize assembly tooling and process for stability and robustness

With Virtual Assembly...

- Evaluate and iterate tooling design through simulation

Features in Hexagon's Virtual Assembly

Customize with "Apps"

Simplify and streamline specific workflows.

Examples of Virtual Assembly Apps

Model setup automation

Model update automation

Welding sequence optimization

Clamping sequence optimization

Clamping position optimization

Clamp creation optimization

Fixture stability analysis (drill-hole method)

Export to metrology reporting automation

Automated FE meshing lowers barrier to entry

Easily generate an ideal mesh for manufacturing process simulation

Import CAD or existing FE mesh

Create or import weld spot locations

Select mesh parameters (or predefined defaults)

Auto generate welding FE mesh with refinement

Both spot and line welds supported

"One click" solution requires no special skills

Multi-physics process simulation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Incorporate real-world assembly process information

Accurate process modelling based on real world process inputs ensures that simulation results reflect reality

Model to mirror the real-world processes

Multi-station assembly

Process timing

Process parameters

Clamping and unclamping behavior

Use actual tooling or create in the GUI

Integrate metrology data via robust geometry morphing

Virtual Assembly incorporates captured metrology (scan) data and morphs geometry so that assembly simulation accurately reflect reality

Metrology data or forming simulation as primary reality data sources

Morph geometry to match the real part shape

Non-nominal shape used in assembly simulation

Capable of morphing of individual parts and multi-part sub-assemblies

Complete scans not required - can be one-sided or partial (incomplete) scan

Realistic gravity orientation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications and considers process specific behaviors.

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Forming simulation data

Integrate forming simulation data to improve assembly model fidelity and accuracy.

Forming history will have an impact on result accuracy.

Various sources of forming simulation data

One-step simulation (can be run in the background)

Incremental simulation

From 3rd party forming simulation software

Customize with "Apps"

Simplify and streamline specific workflows.

Examples of Virtual Assembly Apps

Model setup automation

Model update automation

Welding sequence optimization

Clamping sequence optimization

Clamping position optimization

Clamp creation optimization

Fixture stability analysis (drill-hole method)

Export to metrology reporting automation

Automated FE meshing lowers barrier to entry

Easily generate an ideal mesh for manufacturing process simulation

Import CAD or existing FE mesh

Create or import weld spot locations

Select mesh parameters (or predefined defaults)

Auto generate welding FE mesh with refinement

Both spot and line welds supported

"One click" solution requires no special skills

Multi-physics process simulation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Incorporate real-world assembly process information

Accurate process modelling based on real world process inputs ensures that simulation results reflect reality

Model to mirror the real-world processes

Multi-station assembly

Process timing

Process parameters

Clamping and unclamping behavior

Use actual tooling or create in the GUI

Integrate metrology data via robust geometry morphing

Virtual Assembly incorporates captured metrology (scan) data and morphs geometry so that assembly simulation accurately reflect reality

Metrology data or forming simulation as primary reality data sources

Morph geometry to match the real part shape

Non-nominal shape used in assembly simulation

Capable of morphing of individual parts and multi-part sub-assemblies

Complete scans not required - can be one-sided or partial (incomplete) scan

Realistic gravity orientation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications and considers process specific behaviors.

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Forming simulation data

Integrate forming simulation data to improve assembly model fidelity and accuracy.

Forming history will have an impact on result accuracy.

Various sources of forming simulation data

One-step simulation (can be run in the background)

Incremental simulation

From 3rd party forming simulation software

Customize with "Apps"

Simplify and streamline specific workflows.

Examples of Virtual Assembly Apps

Model setup automation

Model update automation

Welding sequence optimization

Clamping sequence optimization

Clamping position optimization

Clamp creation optimization

Fixture stability analysis (drill-hole method)

Export to metrology reporting automation

Customize with "Apps"

Simplify and streamline specific workflows.

Examples of Virtual Assembly Apps

Model setup automation

Model update automation

Welding sequence optimization

Clamping sequence optimization

Clamping position optimization

Clamp creation optimization

Fixture stability analysis (drill-hole method)

Export to metrology reporting automation

Automated FE meshing lowers barrier to entry

Easily generate an ideal mesh for manufacturing process simulation

Import CAD or existing FE mesh

Create or import weld spot locations

Select mesh parameters (or predefined defaults)

Auto generate welding FE mesh with refinement

Both spot and line welds supported

"One click" solution requires no special skills

Multi-physics process simulation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Incorporate real-world assembly process information

Accurate process modelling based on real world process inputs ensures that simulation results reflect reality

Model to mirror the real-world processes

Multi-station assembly

Process timing

Process parameters

Clamping and unclamping behavior

Use actual tooling or create in the GUI

Integrate metrology data via robust geometry morphing

Virtual Assembly incorporates captured metrology (scan) data and morphs geometry so that assembly simulation accurately reflect reality

Metrology data or forming simulation as primary reality data sources

Morph geometry to match the real part shape

Non-nominal shape used in assembly simulation

Capable of morphing of individual parts and multi-part sub-assemblies

Complete scans not required - can be one-sided or partial (incomplete) scan

Realistic gravity orientation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications and considers process specific behaviors.

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Forming simulation data

Integrate forming simulation data to improve assembly model fidelity and accuracy.

Forming history will have an impact on result accuracy.

Various sources of forming simulation data

One-step simulation (can be run in the background)

Incremental simulation

From 3rd party forming simulation software

Customize with "Apps"

Simplify and streamline specific workflows.

Examples of Virtual Assembly Apps

Model setup automation

Model update automation

Welding sequence optimization

Clamping sequence optimization

Clamping position optimization

Clamp creation optimization

Fixture stability analysis (drill-hole method)

Export to metrology reporting automation

Automated FE meshing lowers barrier to entry

Easily generate an ideal mesh for manufacturing process simulation

Import CAD or existing FE mesh

Create or import weld spot locations

Select mesh parameters (or predefined defaults)

Auto generate welding FE mesh with refinement

Both spot and line welds supported

"One click" solution requires no special skills

Multi-physics process simulation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Incorporate real-world assembly process information

Accurate process modelling based on real world process inputs ensures that simulation results reflect reality

Model to mirror the real-world processes

Multi-station assembly

Process timing

Process parameters

Clamping and unclamping behavior

Use actual tooling or create in the GUI

Integrate metrology data via robust geometry morphing

Virtual Assembly incorporates captured metrology (scan) data and morphs geometry so that assembly simulation accurately reflect reality

Metrology data or forming simulation as primary reality data sources

Morph geometry to match the real part shape

Non-nominal shape used in assembly simulation

Capable of morphing of individual parts and multi-part sub-assemblies

Complete scans not required - can be one-sided or partial (incomplete) scan

Realistic gravity orientation

Virtual Assembly solution captures critical multi-physics without inappropriate simplifications and considers process specific behaviors.

Resistance spot welding or line welding / brazing

Thermal-mechanical or mechanical solving approach

Contact and friction

Realistic clamping and fixturing behaviors

Non-linear, elastic and plastic material behavior

Forming simulation data

Integrate forming simulation data to improve assembly model fidelity and accuracy.

Forming history will have an impact on result accuracy.

Various sources of forming simulation data

One-step simulation (can be run in the background)

Incremental simulation

From 3rd party forming simulation software

Customize with "Apps"

Simplify and streamline specific workflows.

Examples of Virtual Assembly Apps

Model setup automation

Model update automation

Welding sequence optimization

Clamping sequence optimization

Clamping position optimization

Clamp creation optimization

Fixture stability analysis (drill-hole method)

Export to metrology reporting automation

Your benefits with Hexagon Virtual Assembly

![]() Reduce Cost - By reducing and eventually eliminating the need for physical prototypes, the cost of a product program can be significantly reduced. Also the ability to address changes earlier in the process before tooling is built drives further cost reduction.

Reduce Cost - By reducing and eventually eliminating the need for physical prototypes, the cost of a product program can be significantly reduced. Also the ability to address changes earlier in the process before tooling is built drives further cost reduction.

![]() Reduce Time - Eliminating the dependence on physical parts to perform assembly tryouts, and the time required to perform and check the tryouts themselves will dramatically reduce the calendar days required for a new product program. The ability to address changes earlier in the process before tooling is built means that any changes can be implemented earlier and faster.

Reduce Time - Eliminating the dependence on physical parts to perform assembly tryouts, and the time required to perform and check the tryouts themselves will dramatically reduce the calendar days required for a new product program. The ability to address changes earlier in the process before tooling is built means that any changes can be implemented earlier and faster.

![]() Improved Quality - By enabling a holistic evaluation of the design and process earlier in the product development cycle, companies are able to better optimize their design and process, and drive better quality products.

Improved Quality - By enabling a holistic evaluation of the design and process earlier in the product development cycle, companies are able to better optimize their design and process, and drive better quality products.

![]() Sustainability - Saving material, energy, and resources by replacing expensive physical tryouts with virtual prototypes.

Sustainability - Saving material, energy, and resources by replacing expensive physical tryouts with virtual prototypes.

Flyers & Brochures

Solutions brief

Hexagon Virtual Assembly

Brochure

Simufact Welding

Flyer

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

Solutions brief

Hexagon Virtual Assembly

Brochure

Simufact Welding

Flyer

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

Solutions brief

Hexagon Virtual Assembly

Brochure

Simufact Welding

Flyer

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

Solutions brief

Hexagon Virtual Assembly

Brochure

Simufact Welding

Flyer

HxGN Virtual Manufacturing Suite

Flyer