How Hexagon creates value for the healthcare and life sciences industry

Driving digital transformation and process automation in healthcare

The healthcare and life sciences industry affects everyone. Hexagon is helping manufacturers in this sector innovate more quickly and cost-effectively with a range of data-focused solutions. Our technologies promote autonomy and digital transformation for optimised medical product development.

Accelerating product development in healthcare

Companies in the healthcare and life sciences industry must maintain growth, develop innovative products and devices, reduce costs and mitigate risk while meeting compliance regulations.

In this fast-growing globalised industry, being able to adapt quickly is vital to remain competitive against new players entering the market. Digitalising workflows for product development, asset management, quality assurance and process controls helps manufacturers build resilience and agility while improving time-to-market. Agility will become increasingly critical as the industry becomes more consumer-focused with more personalised products and therapies. Digital solutions are a key enabler of more agile, automated processes.

Across medical devices, dental, patient care and pharmaceuticals, there is a common need for smarter, more connected systems that allow the healthcare and life science industries to reach new levels of product quality.

Accelerating consumer product innovation

Expediting time-to-market and reducing costs are ever-present demands in healthcare and life sciences. Companies need to establish cross-departmental collaboration in order to achieve rapid innovation for products and services that deliver new benefits. Hexagon’s solutions help healthcare and life science companies digitalise processes to achieve their targets:

- CFD-enabled fluid simulation for increased yields in bioreactors maximises efficiencies in pharmaceutical development

- CAE simulation for product optimisation and validation within the design process reduces physical product iterations

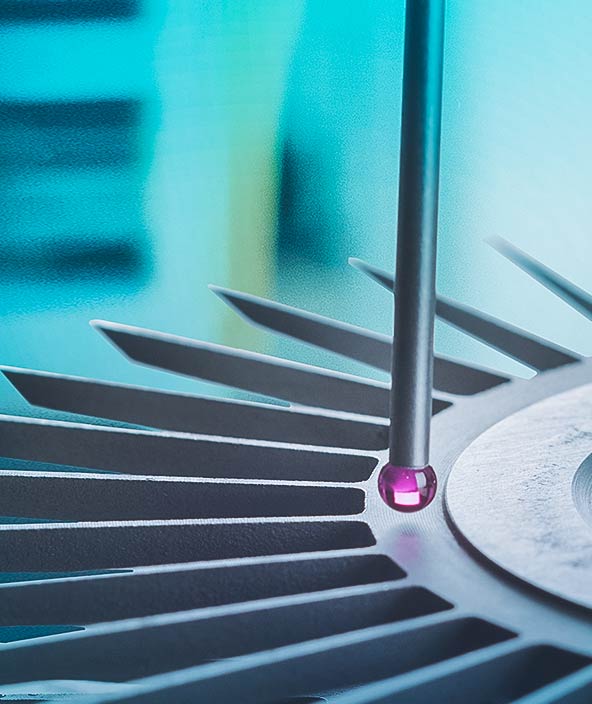

- CT scanning and additive manufacturing platform for implants and prosthetics facilitates the perfect fit for individuals

- Connected end-to-end digital thread for seamless data-sharing enables more informed decisions

- Non-contact inspection captures metrology data to ensure quality and accuracy standards are met