PTA plastics clears bottlenecks, slashes downtime with Hexagon

Quality CMM technology and exceptional service from Hexagon are the difference makers delivering improved efficiency in industrial plastic moulding, with timesavings as high as 20 percent

Founded in 1953 with two facilities – in Connecticut and Colorado – PTA Plastics is a progressive custom plastic injection moulder specialising in engineering for low and medium-volume and high-mix solutions. An in-house tool room with deep mould-making competencies led by a cohesive team of employee-owners, PTA Plastics serves the medical, defence/security and business equipment industries.

Challenge: Clear the quality bottleneck

When PTA Plastics’ previous metrology solution became a bottleneck, its quality team quickly realised it needed an upgrade. “Our previous CMM was relatively old, and we had a lot of issues with it,” explained Madelynn Vazquez, Lead Quality Technician at PTA Plastics. “It was incredibly slow and would often simply stop in the middle of a program. It required a lot of babysitting. It also had limitations on what it could measure, forcing us to use different pieces of equipment to accomplish a single measuring task.”

Solution: Capabilities that “blow everyone else out of the water”

PTA Plastics’ quality team knew it needed a powerful, efficient metrology solution – and having used Hexagon solutions elsewhere in its operations, decided to look there first. “We’d been using Hexagon equipment for many years, so when we needed new equipment, it was a no-brainer – we immediately decided to look and see what Hexagon could provide,” explained Mary Beth Morris, Quality Assurance Manager at PTA Plastics.

Challenge: Clear the quality bottleneck

When PTA Plastics’ previous metrology solution became a bottleneck, its quality team quickly realised it needed an upgrade. “Our previous CMM was relatively old, and we had a lot of issues with it,” explained Madelynn Vazquez, Lead Quality Technician at PTA Plastics. “It was incredibly slow and would often simply stop in the middle of a program. It required a lot of babysitting. It also had limitations on what it could measure, forcing us to use different pieces of equipment to accomplish a single measuring task.”

Solution: Capabilities that “blow everyone else out of the water”

PTA Plastics’ quality team knew it needed a powerful, efficient metrology solution – and having used Hexagon solutions elsewhere in its operations, decided to look there first. “We’d been using Hexagon equipment for many years, so when we needed new equipment, it was a no-brainer – we immediately decided to look and see what Hexagon could provide,” explained Mary Beth Morris, Quality Assurance Manager at PTA Plastics.

With Hexagon’s solutions, we can get the whole picture to the people making tool changes based on our data.

Mary Beth Morris

Quality Assurance Manager at PTA Plastics

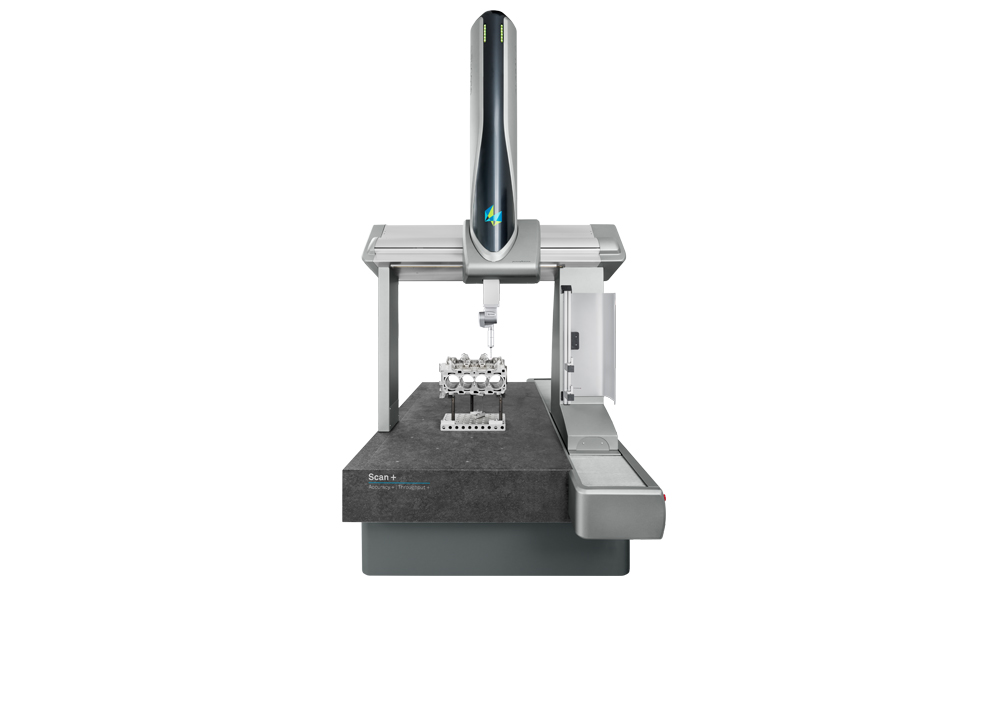

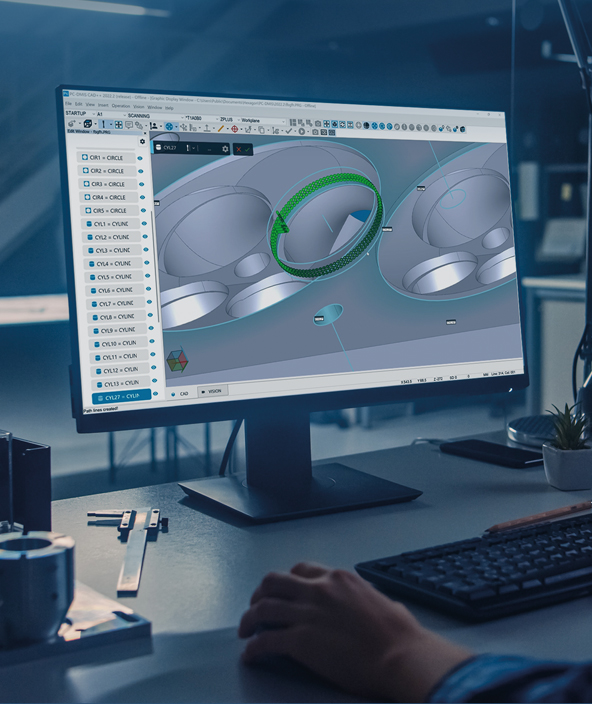

The quality team ultimately opted for Hexagon’s 7.10.7 GLOBAL Scan+ and Hexagon’s PC-DMIS software and has been delighted with its decision. “We use Hexagon’s GLOBAL CMM and PC-DMIS software for in-process testing and validating new parts. We’ve been able to work faster while improving precision and accuracy,” said Josh Horvath, Quality Engineer at PTA Plastics. “In my opinion, PC-DMIS is the industry standard CMM software. So many people use PC-DMIS; you can send a programme to a supplier or a customer, and they can send the programme back. Being able to do that is huge.”

“Along with the CMM, we also purchased a scanning head that allows us to scan a larger portion of the parts we are measuring – which is important when qualifying and validating these tools. With Hexagon’s solutions, we can get the whole picture to the people making tool changes based on our data,” Morris said.

PTA Plastics was also impressed by Hexagon’s level of service. “This is the first shop I’ve worked in where we’ve used Hexagon, and Hexagon’s customer service and technical support capabilities just blow everyone else out of the water. I’ve worked with many of Hexagon’s major competitors, and I’m absolutely astounded,” said Horvath.

“For example, last summer, we had an air bearing go out on a Friday, and Hexagon’s tech was waiting for me at the door at 7:30 Saturday morning so I could let him in to fix it. That kind of attention to detail is huge because we only have one – so when it goes down, we’re in trouble. Hexagon has been a great partner – I don’t think we can say too many good things,” Horvath shared.

Hexagon’s training has helped PTA Plastics’ quality team quickly get up to speed with the solution, allowing the company to work more efficiently and effectively. “I’ve gained a lot of experience through Hexagon’s level 1 and level 2 training, and I can share that knowledge with the rest of the group here at PTA, which is a major benefit. Like Josh said, Hexagon’s training blows everyone else out of the water. And from a technical standpoint, when you’re using the machine, the software is so user-friendly. I can show a project manager exactly what the issue could be right then and there using Hexagon’s software,” said Vazquez.

Results: Reduced downtime, significant time savings

Since implementing Hexagon’s equipment and software solutions, PTA Plastics has recognised significant time savings and greater accuracy and precision. “Hexagon’s GLOBAL Scan+ has allowed us to be much more accurate and efficient than our previous solution. For example, with our previous solution, a particular program might take 15 minutes; with Hexagon in place, we could run the program in just 12 minutes, a 20 percent time saving,” Vazquez said.

She continued, “Hexagon’s probe has also been a massive help for us. We make and test some very complex parts, and it allows us to have a better understanding of things like how the materials may be shrinking. We now have a better sense of how to fix some of the problems that we had.”

According to Horvath, working with Hexagon has also slashed PTA Plastics’ downtime. “I think the biggest difference Hexagon has made for us has been in terms of downtime. It’s like trading in an old Corolla for a Ferrari. We’ve gone from having to hit the engine block with a sledgehammer to get things started to simply being able to get in and go.”

PTA Plastics’ customers have benefitted from the company’s partnership with Hexagon, as have its internal teams. “If our sister plant in Colorado or our customers need help in any way, we can take the programs they developed and do what we need to do here — and vice versa — we’re able to send over programs and they can load it up quickly and run as needed,” said Morris.

Currently, PTA Plastics is taking full advantage of Hexagon’s training opportunities and considering additional equipment purchases. And as far as the quality team is concerned, Hexagon will always be its first choice. “When someone starts talking about what’s new and what’s cutting edge, Hexagon is the first place we go. And the big reason for that is Hexagon’s support, both in training and service. Hexagon provides us with a personal touch that we’ve never gotten from another company before,” Horvath concluded.

“Along with the CMM, we also purchased a scanning head that allows us to scan a larger portion of the parts we are measuring – which is important when qualifying and validating these tools. With Hexagon’s solutions, we can get the whole picture to the people making tool changes based on our data,” Morris said.

PTA Plastics was also impressed by Hexagon’s level of service. “This is the first shop I’ve worked in where we’ve used Hexagon, and Hexagon’s customer service and technical support capabilities just blow everyone else out of the water. I’ve worked with many of Hexagon’s major competitors, and I’m absolutely astounded,” said Horvath.

“For example, last summer, we had an air bearing go out on a Friday, and Hexagon’s tech was waiting for me at the door at 7:30 Saturday morning so I could let him in to fix it. That kind of attention to detail is huge because we only have one – so when it goes down, we’re in trouble. Hexagon has been a great partner – I don’t think we can say too many good things,” Horvath shared.

Hexagon’s training has helped PTA Plastics’ quality team quickly get up to speed with the solution, allowing the company to work more efficiently and effectively. “I’ve gained a lot of experience through Hexagon’s level 1 and level 2 training, and I can share that knowledge with the rest of the group here at PTA, which is a major benefit. Like Josh said, Hexagon’s training blows everyone else out of the water. And from a technical standpoint, when you’re using the machine, the software is so user-friendly. I can show a project manager exactly what the issue could be right then and there using Hexagon’s software,” said Vazquez.

Results: Reduced downtime, significant time savings

Since implementing Hexagon’s equipment and software solutions, PTA Plastics has recognised significant time savings and greater accuracy and precision. “Hexagon’s GLOBAL Scan+ has allowed us to be much more accurate and efficient than our previous solution. For example, with our previous solution, a particular program might take 15 minutes; with Hexagon in place, we could run the program in just 12 minutes, a 20 percent time saving,” Vazquez said.

She continued, “Hexagon’s probe has also been a massive help for us. We make and test some very complex parts, and it allows us to have a better understanding of things like how the materials may be shrinking. We now have a better sense of how to fix some of the problems that we had.”

According to Horvath, working with Hexagon has also slashed PTA Plastics’ downtime. “I think the biggest difference Hexagon has made for us has been in terms of downtime. It’s like trading in an old Corolla for a Ferrari. We’ve gone from having to hit the engine block with a sledgehammer to get things started to simply being able to get in and go.”

PTA Plastics’ customers have benefitted from the company’s partnership with Hexagon, as have its internal teams. “If our sister plant in Colorado or our customers need help in any way, we can take the programs they developed and do what we need to do here — and vice versa — we’re able to send over programs and they can load it up quickly and run as needed,” said Morris.

Currently, PTA Plastics is taking full advantage of Hexagon’s training opportunities and considering additional equipment purchases. And as far as the quality team is concerned, Hexagon will always be its first choice. “When someone starts talking about what’s new and what’s cutting edge, Hexagon is the first place we go. And the big reason for that is Hexagon’s support, both in training and service. Hexagon provides us with a personal touch that we’ve never gotten from another company before,” Horvath concluded.