Actran TM

Actran TM

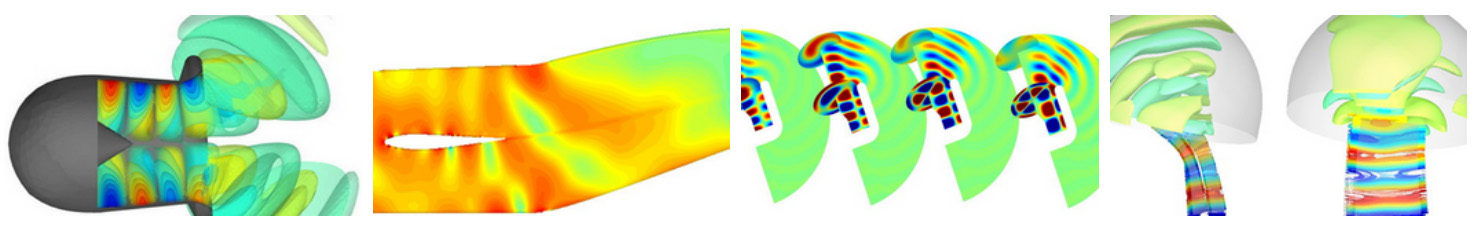

A powerful acoustic CAE tool for turbomachinery noise prediction

Ready to learn more?

Use Actran TM to analyze the sound radiated by turbomachinery and to optimize the related acoustic treatments. One of the challenges of acoustic CAE methods is handling of large models associated to high wave number and to large geometrical size and complexity. Actran TM provides efficient solver technologies to address this problem, which includes advanced parallel processing.

In addition to studying aircraft engines, Actran TM can be used to analyze inlet and outlet liners for helicopter turbines, environmental control systems, and auxiliary power units, and for non-aerospace applications like computer cooling systems. Actran TM can be complemented by Actran DGM to solve problems involving complex shear layers and flow gradients occurring at engine exhaust.

Sample Applications:

- Aircraft engine noise, including nacelle design

- Ducted cooling systems (electronic devices)

- Blower systems (air conditioning modules)

- Helicopter turbine noise

Learn more about Actran products and services at www.fft.be

-

Case Studies

-

Collateral

-

Videos