Laser scanning closes the digital gap in 3D printing and high-end milling workflow

GF Machining Solutions, Biel, Switzerland

Engineering Reality 2024 volume 1

Accelerate Smart Manufacturing

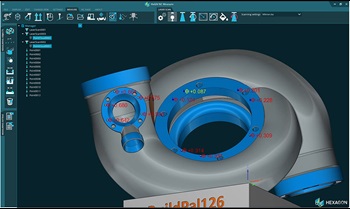

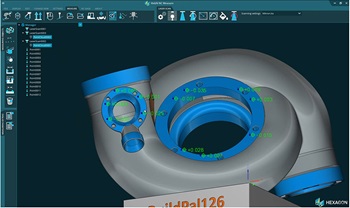

GF Machining Solutions used Hexagon’s laser scanning solution for machine tools to dramatically reduce the process time for the alignment, digitisation and machining of a 3D-printed Formula 1 turbocharger.

GF Machining Solutions was tasked with creating an optimal workflow for additive and subtractive manufacturing of a Formula 1 turbocharger. By incorporating Hexagon’s laser scanning technology, they overcame vexing alignment and measurement challenges when moving between a digitalised 3D printing process and subsequent machining steps, resulting in a more efficient workflow and significant reductions in both time and costs.

Based in Switzerland, the company is a globally acting division of the Georg Fischer Group with its own sales companies in over 50 countries. In addition, the division operates production facilities and research and development centres in Switzerland, the USA, Sweden and China.

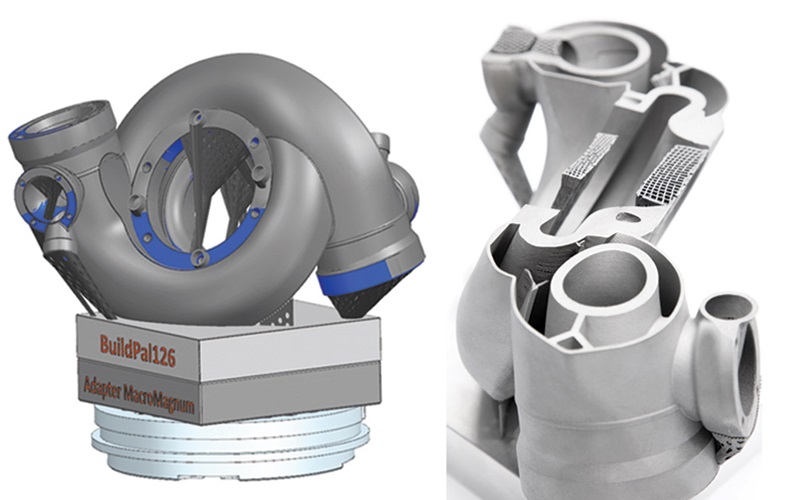

In response to a customer request to produce a turbocharger for use in a Formula 1 car, GF was asked to develop the best possible manufacturing workflow, from design, simulation and production through to qualification.

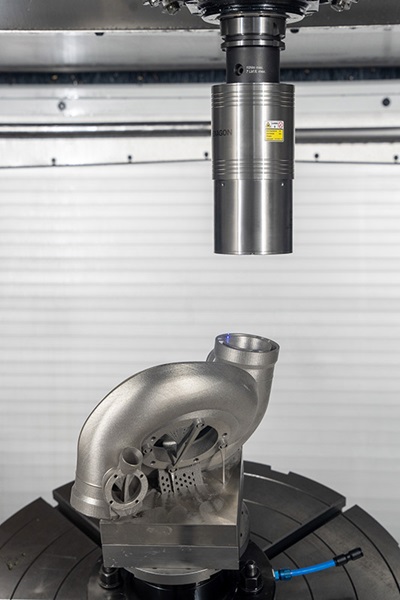

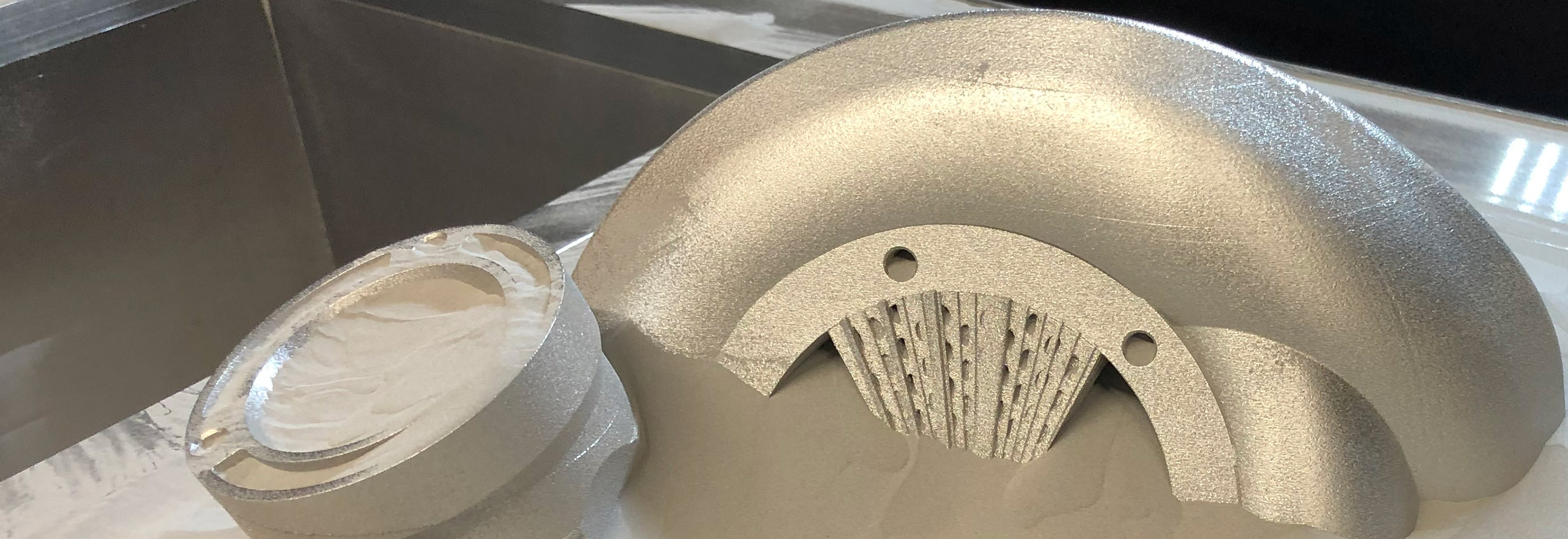

The part is a double-walled F1 turbocharger, made from a nickel-based heat resistant superalloy (Inconel LaserForm® Ni718 A) and manufactured using additive and subtractive processes.

In Formula 1, double-walled turbochargers are needed to bypass turbo lag and increase efficiency, and thermal insulation is necessary for their effective operation. However, creating an air gap using a double-wall construction that prevents the heat within the core from reaching the outer shell can be tough to manage with casting, which falters with thin wall thicknesses.

In short, for double-walled applications, metal casting is not an option for producing the basic shape, which is why GF Casting Solutions turned to its sister company, GF Machining Solutions, to make the part using an additive process.

GF experts performed the 3D printing using an in-house DMP Flex/Factory 350 machine, which ensures efficient production of very dense, pure metal parts and, with high throughput and repeatability, can produce high-quality precision parts. Including preparation, it took over 55 hours to complete the finished blank part – a time which gives a strong hint at its high cost.

Reference points – a challenge when transitioning between manufacturing steps

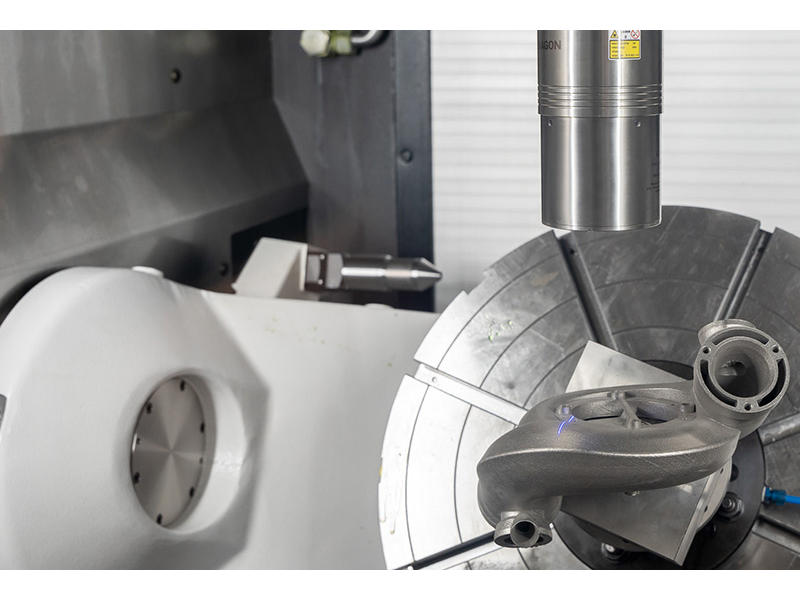

The clamping of parts on a machine tool is typically aligned to ensure the surfaces to be milled can be reached as easily as possible. On a 3D printer, however, the part’s orientation can be entirely different to ensure each element can be printed efficiently. In addition, there are distortions in the part due to the printing process itself. As mentioned, this was a factor with the turbocharger as well.

Since no updated CAD file was available from the 3D print, this meant a rough alignment had to first be carried out on the milling machine, which takes a few hours using conventional tactile methods.

“This system was a revelation for us – we were now able to close the digital gap between these two manufacturing steps,” says Zaugg.

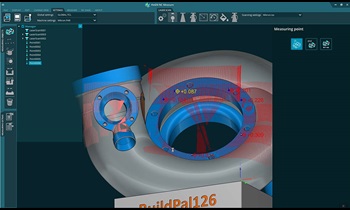

After another scan, the Best-Fit function of HxGN NC Measure determined the optimal displacement of the workpiece zero point and transferred this to the machine control.

Thanks to the known surface dimensions and the optimally selected zero point, GF could now precisely and efficiently mill the turbocharger’s functional surfaces and connecting elements. This final production phase was significantly shortened by using laser scanning to align and measure the part. And it also ensured there was enough allowance for further processing, preventing costly scrap from being produced.

Motorsports is all about speed. Achieving success in the realm of manufacturing for high-performance racing demands the perfect combination of digital solutions and production equipment to ensure rapid and cost-efficient production.