Tokushima University and Helical Fusion Co., Ltd. Utilize "MSC Apex" in 3D Neutron Transport Monte Carlo Simulation Calculations for Next Generation Helical-type Fusion Reactor

31 May 2023

Hexagon Manufacturing Intelligence division (Chiyoda-ku, Tokyo; President: Masaki Konno) announced that Department of Radiation Science and Technology, School of Health Sciences, Faculty of Medicine, Tokushima University, (Tokushima City, Tokushima Prefecture, Japan; Minoru Sakama Laboratory) (hereinafter referred to as "Tokushima University") and Helical Fusion Co., Ltd. (Co-founders: Takaya Taguchi, Junichi Miyazawa, and others) (hereinafter referred to as "Helical Fusion") have been using "MSC Apex" for the generation of the MSC Nastran input data in 3D neutron transport Monte Carlo simulation calculations of next-generation helical-type nuclear fusion.

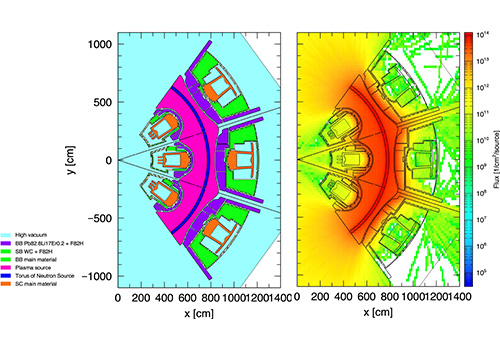

Tokushima University has performed 3D neutron transport calculations for advanced design blanket of a helical-type nuclear fusion reactor to evaluate TBR (Tritium Breeding Ratio) in an advanced design blanket of a helical-type fusion reactor under the joint research program of the National Institute for Fusion Science, Japan, where a helical-type plasma experimental device is located. In July 2022, they started joint research with Helical Fusion on this 3D neutron transport Monte Carlo simulation calculation, i.e., PHITS calculation code.

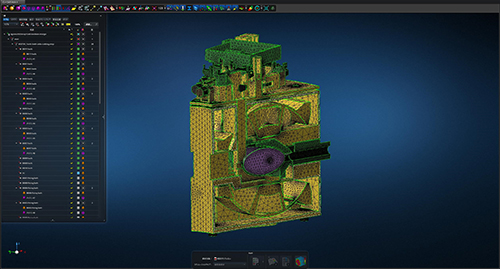

In order to evaluate neutron transport in advance with accuracy, it is especially important to accurately represent the target structure in the computational domain in radiation transport analysis in advance. In this research, high resolution representing the design of the next-generation helical-type nuclear fusion reactor by Helical Fusion is inevitable. However, it is extremely difficult to accurately represent complex design structures like a helical structure in PHITS calculation space. Tokushima University, therefore, used "MSC Apex Modeler" to generate MSC Nastran input data to be imported into the PHITS calculation code from the 3D CAD data of the next-generation helical-type nuclear fusion reactor. In this workflow, 3D CAD data was imported into MSC Apex Modeler, geometries were edited, and solid mesh was generated to obtain the input data in MSC Nastran input data format. Then, the file output from MSC Apex was loaded in the PHITS calculation code and the calculation was performed successful.

Before using MSC Apex, the conventional method could not handle CAD data. Therefore, they had no way to deal with errors such as intersections generated during meshing, or could not handle the data in the GUI. However, various geometry editing and solid meshing functions in MSC Apex allow the user to detect intersections and other errors in the GUI and to visually edit geometries with advanced tools such as “Vertex/Edge Drag”.

Professor Minoru Sakama, Department of Radiation Science and Technology, School of Health Sciences, Faculty of Medicine, Tokushima University, says that “In radiation transport simulation analysis, workflows to import the data of complex structures such as helical-type nuclear fusion reactors and curved structures such as NURBS, including the human body, into radiation transport calculation domain are not well known. We expect that MSC Apex Modeler, advanced solid meshing software, will be widely used increasingly and new solvers for radiation-related matters will be born in the future.”

All trademarks are the property of their respective owners.

About Helical Fusion Co., Ltd.

Helical Fusion Co., Ltd. is a start-up company founded in October 2021 by Takaya Taguchi, Junichi Miyazawa, and other co-founders. Helical Fusion designs nuclear fusion reactors, develops and provides elemental technology under their slogan "Humans evolve through nuclear fusion”. Helical Fusion aims to create sustainable and stable energy by helical-type nuclear fusion reactors and to enable the coexistence of humans and the earth for the next million years. For more detail: https://www.helicalfusion.com/en

About Hexagon

Hexagon is a global leader in sensor, software and autonomous technologies. We work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon’s Manufacturing Intelligence division provides solutions that utilize data from design and engineering, production and metrology to make manufacturing smarter. Learn more at hexagonmi.com.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 24,000 employees in 50 countries and net sales of approximately 5.2bn EUR. Learn more at hexagon.com .

Tokushima University has performed 3D neutron transport calculations for advanced design blanket of a helical-type nuclear fusion reactor to evaluate TBR (Tritium Breeding Ratio) in an advanced design blanket of a helical-type fusion reactor under the joint research program of the National Institute for Fusion Science, Japan, where a helical-type plasma experimental device is located. In July 2022, they started joint research with Helical Fusion on this 3D neutron transport Monte Carlo simulation calculation, i.e., PHITS calculation code.

In order to evaluate neutron transport in advance with accuracy, it is especially important to accurately represent the target structure in the computational domain in radiation transport analysis in advance. In this research, high resolution representing the design of the next-generation helical-type nuclear fusion reactor by Helical Fusion is inevitable. However, it is extremely difficult to accurately represent complex design structures like a helical structure in PHITS calculation space. Tokushima University, therefore, used "MSC Apex Modeler" to generate MSC Nastran input data to be imported into the PHITS calculation code from the 3D CAD data of the next-generation helical-type nuclear fusion reactor. In this workflow, 3D CAD data was imported into MSC Apex Modeler, geometries were edited, and solid mesh was generated to obtain the input data in MSC Nastran input data format. Then, the file output from MSC Apex was loaded in the PHITS calculation code and the calculation was performed successful.

Before using MSC Apex, the conventional method could not handle CAD data. Therefore, they had no way to deal with errors such as intersections generated during meshing, or could not handle the data in the GUI. However, various geometry editing and solid meshing functions in MSC Apex allow the user to detect intersections and other errors in the GUI and to visually edit geometries with advanced tools such as “Vertex/Edge Drag”.

Figure 1: Example of solid meshing for a next-generation helical-type fusion reactor design in MSC Apex

Figure 2: Geometry output from radiation transport analysis Monte Carlo simulation calculation PHITS (imported MSC Nastran input data from MSC Apex) and radiation transport results (Trajectory of neutron flux)

Professor Minoru Sakama, Department of Radiation Science and Technology, School of Health Sciences, Faculty of Medicine, Tokushima University, says that “In radiation transport simulation analysis, workflows to import the data of complex structures such as helical-type nuclear fusion reactors and curved structures such as NURBS, including the human body, into radiation transport calculation domain are not well known. We expect that MSC Apex Modeler, advanced solid meshing software, will be widely used increasingly and new solvers for radiation-related matters will be born in the future.”

All trademarks are the property of their respective owners.

About Helical Fusion Co., Ltd.

Helical Fusion Co., Ltd. is a start-up company founded in October 2021 by Takaya Taguchi, Junichi Miyazawa, and other co-founders. Helical Fusion designs nuclear fusion reactors, develops and provides elemental technology under their slogan "Humans evolve through nuclear fusion”. Helical Fusion aims to create sustainable and stable energy by helical-type nuclear fusion reactors and to enable the coexistence of humans and the earth for the next million years. For more detail: https://www.helicalfusion.com/en

About Hexagon

Hexagon is a global leader in sensor, software and autonomous technologies. We work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon’s Manufacturing Intelligence division provides solutions that utilize data from design and engineering, production and metrology to make manufacturing smarter. Learn more at hexagonmi.com.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 24,000 employees in 50 countries and net sales of approximately 5.2bn EUR. Learn more at hexagon.com .

Contact us: (phone: +1-866-866-8681)

Hexagon, Manufacturing Intelligence Marketing Communications Department Akimoto

TEL: 03-6275-0870 Mobile: 080-3524-4302 E-mail: hexagonmi.jp.marketing@hexagon.com

- PressRelease

-

Media Downloads

Hexagon is a global leader in digital reality solutions, combining sensor, software and autonomous technologies. We are putting data to work to boost efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications.

Our technologies are shaping production and people related ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 24,500 employees in 50 countries and net sales of approximately 5.4bn EUR. Learn more at hexagon.com and follow us @HexagonAB.

Media Enquiries

PR Team

Hexagon AB