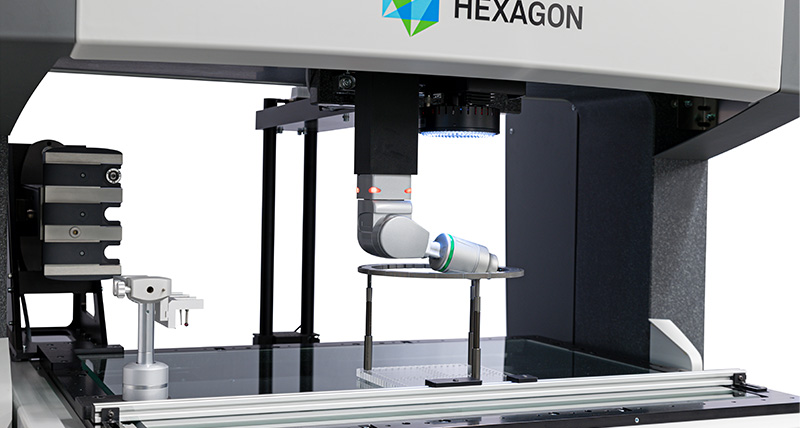

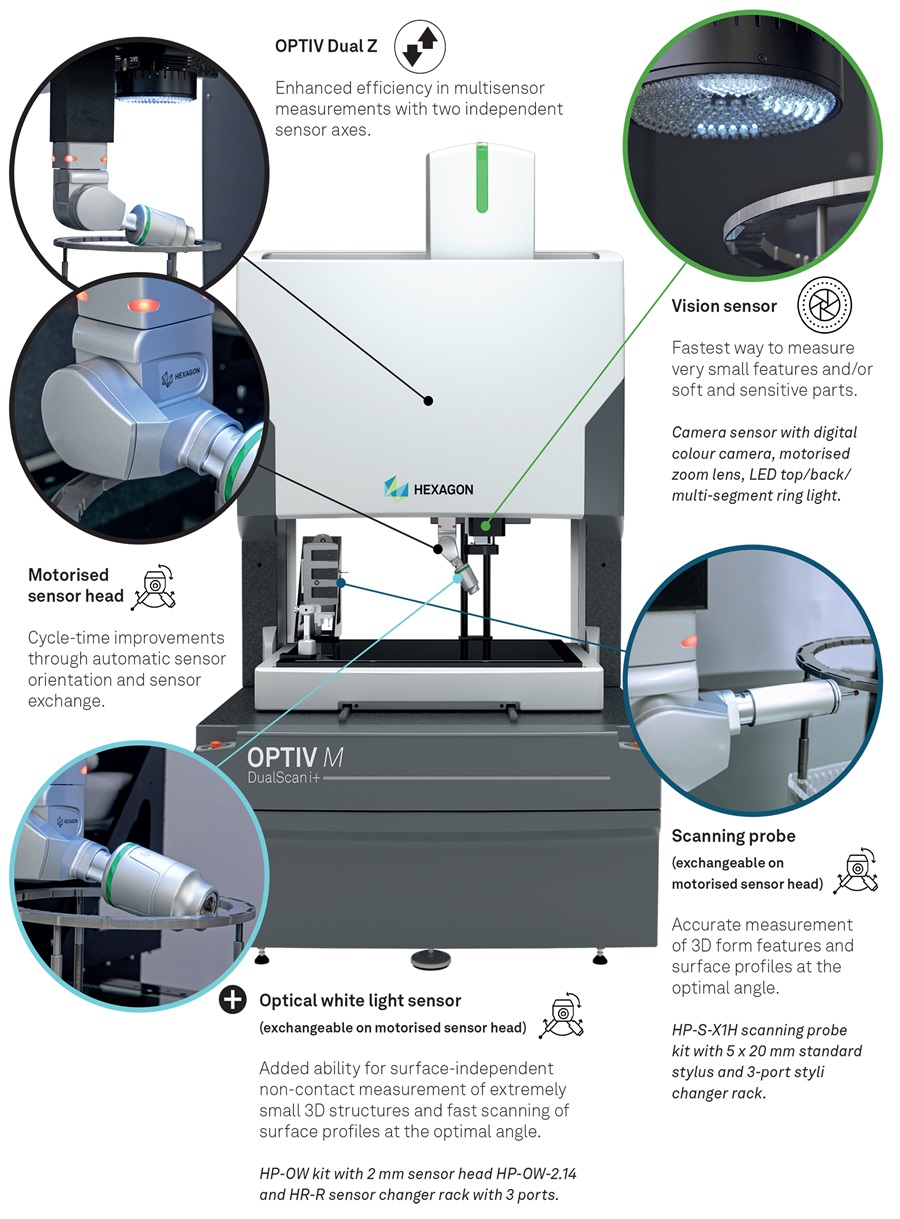

OPTIV M DualScan i+

The ideal solution for single-cycle multisensor measurements of complex, large and heavy 3D parts

Would you like to know more?

OPTIV M DualScan i+ offers measurement time improvements for an extended range of complex precision parts by deploying automatically exchangeable sensors in conjunction with an indexing probe head. This system guarantees optimum feature accessibility for large or heavy parts that must remain stationary within the measuring volume.

- All-in-one metrology solution with two independent sensor axes (OPTIV Dual Z) and automatically exchangeable sensors on a motorised sensor head – camera sensor + scanning probe + optical white light sensor enable complete part capture in one setup and within one automated measurement cycle.

- Future-ready modularity allows for easy in-field upgrade of the base system.

- ISO 10360 compliant 3D measurement performance with high accuracy – optical and tactile.

- Effortless smart manufacturing integration of OPTIV M DualScan i+ due to standardised automation interface and seamless integration with Hexagon’s IoT technologies for remote asset and environment monitoring.

- Intuitive operability of OPTIV M DualScan i+ through a simplified operator interface.

- Future-proof investment fully backed up by Hexagon’s global service and support network.

-

Downloads

Complex large-scale dual-axis sensor measurement

Discover the typical applications suited to complex large-scale dual-axis sensor systems.