I/O Flow Manager

Complete Production Cell Integration System for Coordinate Measuring Machines

Would you like to know more?

I/O Flow Manager is the complete integration solution for installing coordinate measuring machines (CMMs) into a production cell. The all-in-one hardware and software package enables manufacturers to integrate quality assurance directly into production with minimal pre-programming or operator training.

I/O Flow Manager facilitates the integration of CMM hardware into the production environment through a combination of dedicated hardware and software components working together to ensure seamless interfaces with the production equipment within the cell.

The I/O Box, containing a standard industrial connector with a predefined layout, physically connects the CMM into the system whilst the I/O Flow Manager software uses a library of modular functions to interact with the components within the automated cell.

The I/O Flow Manager modular system is developed for full workflow flexibility without the development costs associated with having a bespoke solution created. These software modules function as part of a workflow editor to enable simplified pre-programming with predefined measurement routines that can be tailored to suit the individual application. As requirements change, the measurement routines can easily and quickly be updated from the module library without lengthy downtime periods. Optimised for automated cell integration, the hardware and software package is preconfigured for barcode and RFID readers, enabling the use of automated part recognition systems for increased overall throughput.

Unlike bespoke solutions, the I/O Flow Manager is simple to set up, reducing downtime during installation. The click-and-measure user interface ensures operators of all levels are able to operate the CMM within the production cell by simply selecting the appropriate routine from a predefined list.

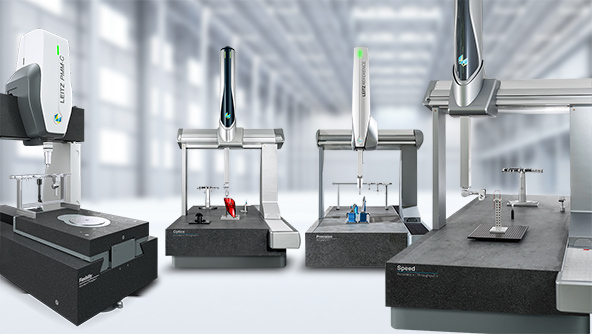

The completely configurable I/O Flow Manager package solution is compatible with the shop-floor hardened TIGO SF CMM and GLOBAL range of machines.

I/O Flow Manager facilitates the integration of CMM hardware into the production environment through a combination of dedicated hardware and software components working together to ensure seamless interfaces with the production equipment within the cell.

The I/O Box, containing a standard industrial connector with a predefined layout, physically connects the CMM into the system whilst the I/O Flow Manager software uses a library of modular functions to interact with the components within the automated cell.

The I/O Flow Manager modular system is developed for full workflow flexibility without the development costs associated with having a bespoke solution created. These software modules function as part of a workflow editor to enable simplified pre-programming with predefined measurement routines that can be tailored to suit the individual application. As requirements change, the measurement routines can easily and quickly be updated from the module library without lengthy downtime periods. Optimised for automated cell integration, the hardware and software package is preconfigured for barcode and RFID readers, enabling the use of automated part recognition systems for increased overall throughput.

Unlike bespoke solutions, the I/O Flow Manager is simple to set up, reducing downtime during installation. The click-and-measure user interface ensures operators of all levels are able to operate the CMM within the production cell by simply selecting the appropriate routine from a predefined list.

The completely configurable I/O Flow Manager package solution is compatible with the shop-floor hardened TIGO SF CMM and GLOBAL range of machines.

Quality control of gearbox housings in an automated production cell

-

Features & Benefits

Bridge CMM

Bridge CMMs offer a range of solutions where accuracy, repeatability and automated dimensional inspection is required.

Buy CMM accessories online

Identify your spare parts with confidence and benefit from fast UPS delivery.