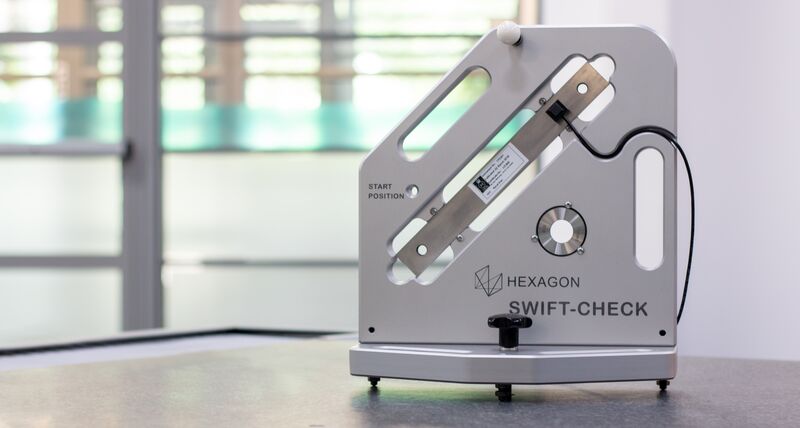

SWIFT CHECK interim testing artefact

Gain confidence in your measurement results

Ready to get started?

Talk to an expert and discover what Hexagon can do for your organization.

Hexagon coordinate measuring machines perform at the leading edge of dimensional measurement technologies. Throughput and accuracy are determined by the sum of every part, including sensors, probe heads, styli. This can make it hard to estimate whether a system is running as smoothly as it should. Therefore, Hexagon recommends checking the performance of a coordinate measuring machine regularly, in order to avoid issues downstream and maintain consistent levels of productivity.

The Hexagon SWIFT CHECK artefact gives operators confidence in the reliability of their measurements by performing quick and simple checks and delivering clear and easy results. The artefact is equipped with a calibrated ring gauge, length bar and sphere that encompasses all the directions and geometries needed to check performance. The artefact can be used on small and medium-sized CMMs from Hexagon.

SWIFT CHECK comes with its own measurement routines for PC-DMIS and QUINDOS software, making it easy to use. It gives operators the assurance they need to confidently perform daily measurements with indexing probe heads equipped with touch trigger or tactile scanning sensors.

The Hexagon SWIFT CHECK artefact gives operators confidence in the reliability of their measurements by performing quick and simple checks and delivering clear and easy results. The artefact is equipped with a calibrated ring gauge, length bar and sphere that encompasses all the directions and geometries needed to check performance. The artefact can be used on small and medium-sized CMMs from Hexagon.

SWIFT CHECK comes with its own measurement routines for PC-DMIS and QUINDOS software, making it easy to use. It gives operators the assurance they need to confidently perform daily measurements with indexing probe heads equipped with touch trigger or tactile scanning sensors.

-

Buy CMM accessories online

-

Features & benefits

-

Technical data

HxGN LIVE Global

Learn how our technologies can digitally transform facilities, assets and workflows to drive productivity.

Buy CMM accessories online

Identify your spare parts with confidence and benefit from fast UPS delivery.