What is HxGN Robotic Automation?

The intuitive, flexible and scalable software solution for robotic inspection cells.

Ready to get started?

Talk to an expert and discover what Hexagon can do for your organization.

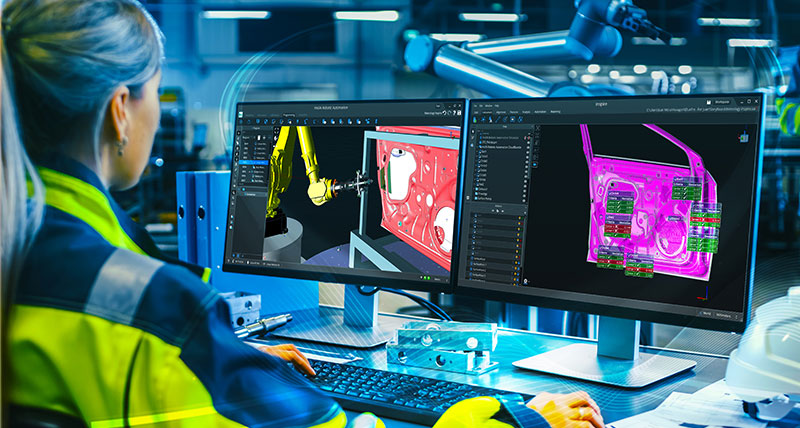

HxGN Robotic Automation is an intuitive, flexible and scalable robotic control software designed to simplify programming for automated measurement and inspection applications.

The HxGN Robotic Automation software provides the toolset to efficiently plan, program and control robotic cells based all major robot suppliers, as well as integrating with the wider manufacturing software ecosystem, simplifying the data acquisition process for smarter manufacturing processes. Created specifically to orchestrate the sensors, software and robotic equipment of an inspection cell from a single, intuitive interface, HxGN Robotic Automation makes automated measurement more accessible, more efficient and more reliable.

Designed to remove the complexity from robot-based automation, HxGN Robotic Automation uses simple UX principles, intuitive workflows, and automated program generation that enable inexpert operators to safely and efficiently program inspection applications. The hardware- and software-agnostic toolset integrates seamlessly with your existing workflows and technologies, and improves the flexibility of your automated inspection cell by easily integrating new sensors, software and robotic equipment so your solution scales to different applications as needed.

To maximise equipment utilisation, HxGN Robotic Automation’s offline programming environment offers accurate path simulation that allows virtual commissioning of the system and rapid deployment of programs to the real cell. Whether your automated inspection cell is off-line, near-line or inline, HxGN Robotic Automation ensures rich data capture without the complexity.

-

Features & benefits

-

Downloads

-

Applications