What's new in Quality Assurance?

Explore the latest features in your version of Q-DAS and eMMA

Plan, measure, optimise. Future-safe!

The latest versions of both product families Q-DAS and eMMA enables a wide range of solutions, from entry-level to AI-powered analytics.

Ready to learn more?

Support materials

- Read more

-

Quality Assurance 2024.2

- Read more

-

Quality Assurance 2024.1

- Read more

-

Quality Assurance 2023.1

- Read more

-

Q-DAS 'TSAF' 14.0.2.2

-

Q-DAS 2024.2

O-QIS/procella 2024.2

Dynamic Inspection & Dynamic Sampling: Reduce Inspection Time while maintaining High Quality Standards

Pain Point: “I want to reduce my Inspection Time in order to reduce production & quality costs and ensure on time delivery, but in the meantime, I want to ensure the quality standards and stability of the production process.”

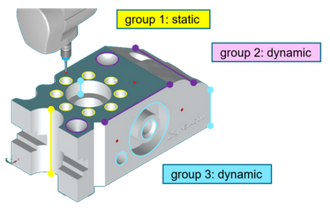

In O-QIS 2024.2 major enhancements have been applied for Dynamic Inspection in O-QIS CMM Reporting and for Dynamic Sampling in Procella to guide the user on how to set, execute, stop, or reset Dynamic Inspection & Dynamic Sampling. This solution allows customers to reduce measurement cycle time, with a user-friendly interface to flatten the learning curve.

Automatic selection of measurement features based on process stability.

In case of Alarms automatically all groups incriminated will be measured until reaching a quality stability, in order to ensure high quality standards and process stability.

Q-DAS Web 2024.2

Enhancement in User Experience (UX): The new menu design makes it easier and more enjoyable for users to navigate.

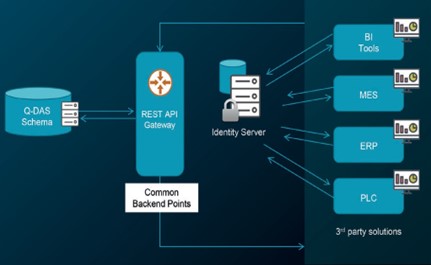

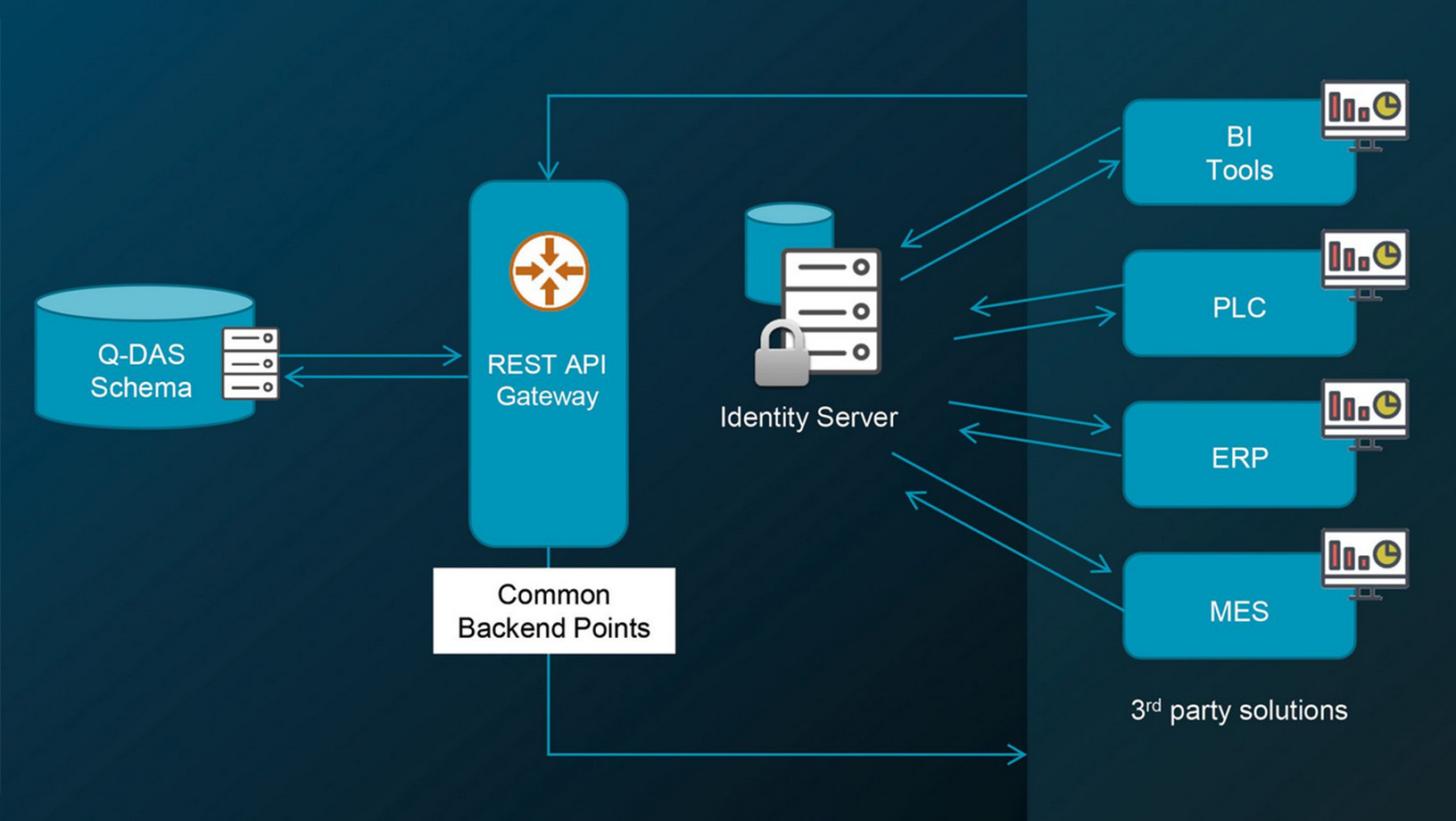

Q-DAS Rest APIs 2024.2

Pain Point: I need to have multiple instances of Rest APIs services installed on the same server, to ensure a certain level of scalability, so if a service is busy I can make request to a different service in parallel. At the same time, we would like to have them on the same server to reduce IT costs.

Solution: Q-DAS Multi-Plant and Multi-Services Rest APIs to install on the same server.

Easy Integration - Rest APIs simplify the integration process, reducing the time and effort required to connect Q-DAS solutions with other systems.

Benefits:

Security - This ensures that only authorized users can access sensitive SPC data.

Coexistence and collaboration between data structures

solaraMP 2024.2

VDA5 enhancements

Pain Points: What type of uncertainty affects my Inspection process? How does uncertainty affect my Inspection process?

Q-DAS solara.MP VDA5 allows user to define and see directly what uncertainty component does affect and how does affect their inspection system and process.

In Q-DAS solara.MP version 2024.2, the user can easily identify if a uncertainty value has not been entered or if it has been entered in a wrong manner, to improve user experience.

-

Q-DAS 2024.1

solara.MP 2024.1

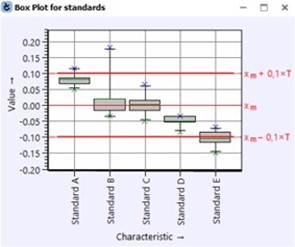

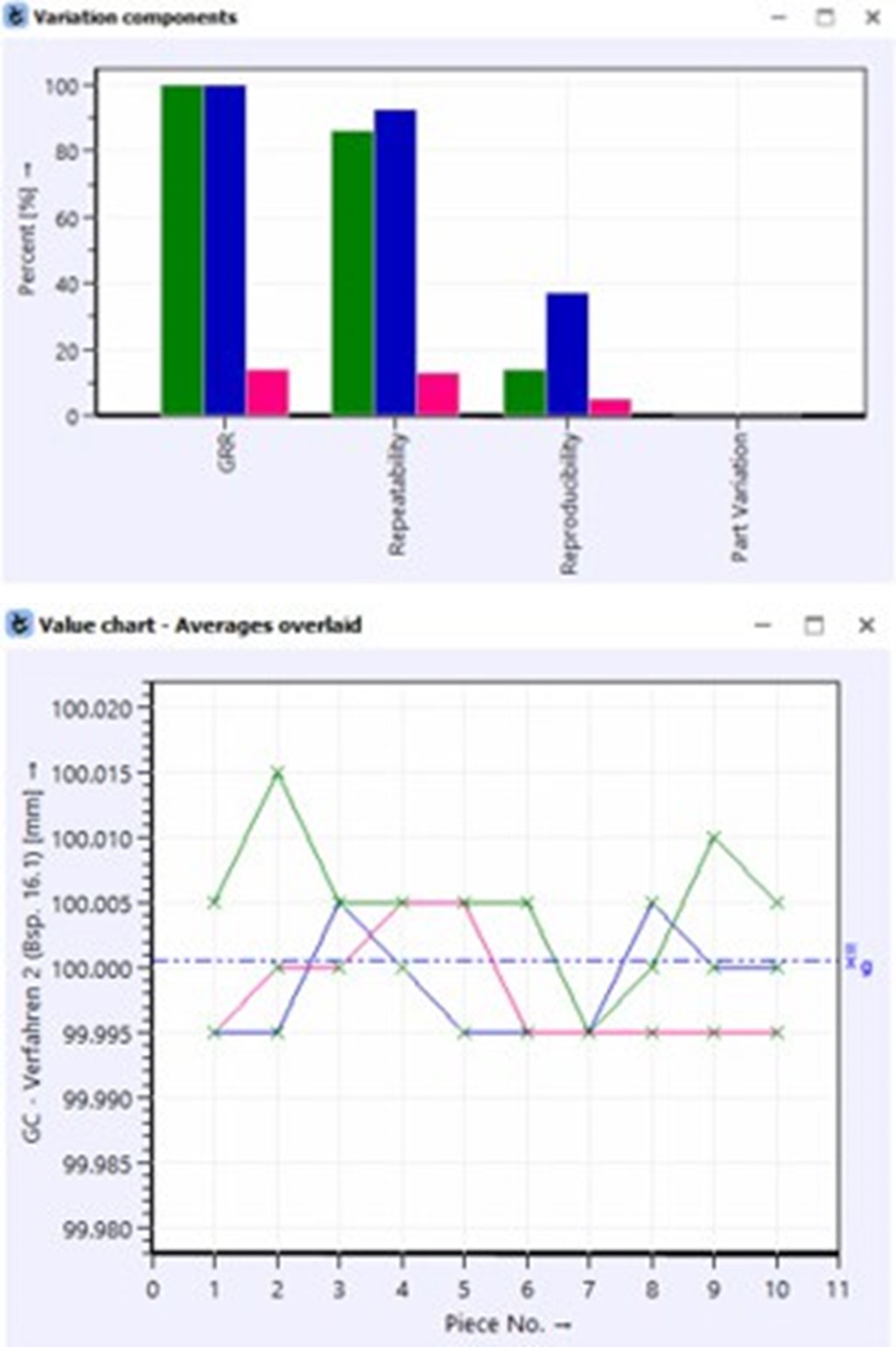

Enhanced charts for an easy root cause analysis.

Persona: Quality Engineer/ Quality Manager

Pain Point: In case my inspection process does not succussed the MSA validation therefore it is not Repeatable and Reliable, I need a simple and user-friendly way to identify the reason of the issue, to promptly fix it when possible

Solution: Q-DAS Solara.MP 2024.1 offers new analysis charts for deeper understanding and troubleshooting (if necessary). If the results are good, then the charts will show you why they are good. If the results are bad, then they will guide you to see where there are opportunities to improve.

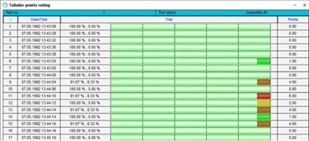

qs-STAT 2024.1Part Evaluation with Attributive Characteristics

Persona: Quality Engineer/ Process Engineer

Pain Point: I need to have an overview and evaluation of a specific part (how many are okay how many not), for all its characteristics, not only for the variable characteristics, but for attribute characteristics as well.

Solution: In Q-DAS qs-STAT 2024.1 users can perform part evaluation analysis for variable and attribute characteristics together.

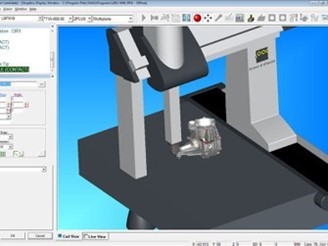

O-QIS 2024.1Dynamic Inspection: Better Integration with PC- DMIS and more user-friendly interface.

Persona: Quality Manager & Shop Floor Manager

Pain Point: Our Inspection Process is very costly and time consuming, we need a solution that reduces the inspection program execution time on the CMM, based on statistical analysis, and it needs to be a solution quite intuitive to set and run (almost no training needed), as is increasingly difficult to find and hire skilled people.

Solution: In O-QIS 2024.1 major enhancements have been applied for Dynamic Inspection to guide the user on how to set, execute, stop, or reset Dynamic Inspection. This solution allows customers to reduce measurement cycle time, whit a user-friendly interface to flatten the learning curve.

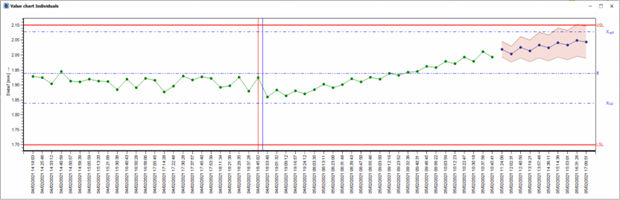

qs-STAT & M-QIS 2024.1New Quality Forecast Model

Persona: Quality/Process Engineer

Pain Point: I would need an effortless way to detect and visualize out of tolerance before they occur and to know when they will occur so I can react accordingly.

Solution: In qs-STAT 2024.1 and M-QIS Engine 2024.1 is available Quality Forecast solution to forecast future quality outcome based on the historical data, a Machine Learning solution functionality that allows users companies to move from a reactive to a proactive way of working, by identifying if a Out of Tolerance will happen and when and therefore been able to plan corrections in a timely manner.

Q-DAS browser based applications 2024.1HTTPS

Persona: IT department

Pain Point: Our IT policy requires an encryption of the data transmission channel to secure against access by outside parties.

Solution: in Q-DAS browser based applications 2024.1, HTTPS configuration is available to0 ensure data security.

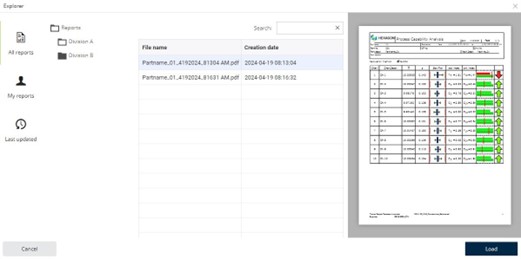

Web Explorer

Persona: Quality Manager

Pain Point: I need to be able to see all the reports generated by M-QIS anywhere at anytime and anywhere within the company network, and I need a structured way to trace and retrieve them, I cannot afford time to spend in searching for the different reports.

Solution: In Q-DAS browser based applications 2024.1, Web Explorer allows users to have a structured folder hierarchy to store and visualize your PDF reports, to easily find the report needed in no time in a user-friendly browser window.

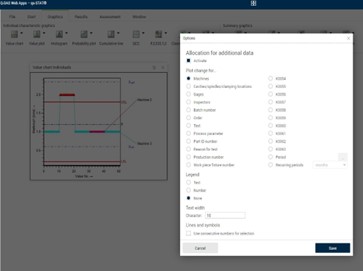

qs-STAT Web 2024.1Additional Data in the value chart in qs-STAT Web

Pain Point: When a characteristic it is not capable, I need a way that allows me to have a deeper understanding and troubleshooting (if necessary), to help me define what variable is affecting my process capability, so I can then apply corrective actions accordingly.

Persona: Quality/Process Engineer

PLV 2024.1procella Alarms in PLV

Persona: Quality ManagerPain Point: I am not able to have KPI and see the quality alarms from my manual gages, currently only from my automated gages, I need to see all the alarms from all the gages in the shopfloor.

Solution: In PLV 2024.1, alarms generated from procella can be viewed in PLV. From now on, alarms can be viewed independently of the technical data flow.

Rest APIs in Q-DAS 2024.1With version 2024.1 we announce the official release of our new REST APIs, offering a gateway to unlocking the full potential of your business applications. Whether you’re looking to streamline workflows, improve customer experiences, or drive innovation, our APIs provide the foundation for success.

Key Benefits:

Flexible Integration: Our REST APIs enable seamless integration with your existing systems.

Security and Compliance: Our REST APIs support industry-standard security mechanisms such as HTTPS, authentication, and authorization, ensuring the confidentiality, integrity, and availability of data exchanged between system.

Customization: With REST APIs, businesses have the power to craft bespoke interfaces and features tailored to their unique needs.

-

Q-DAS 14.0.4

Leveraging integration between products and solution

Connected quality data with REST API beta version

In a world where data and applications must seamlessly communicate, your success hinges on the strength of your connections.

That’s where our REST API's interface comes in — your key to unlocking a world of possibilities.

Benefit:Our REST API's interface empowers you to connect your product with a myriad of services, apps, and platforms. Seamlessly bridge the gaps and create a unified ecosystem that works together harmoniously.

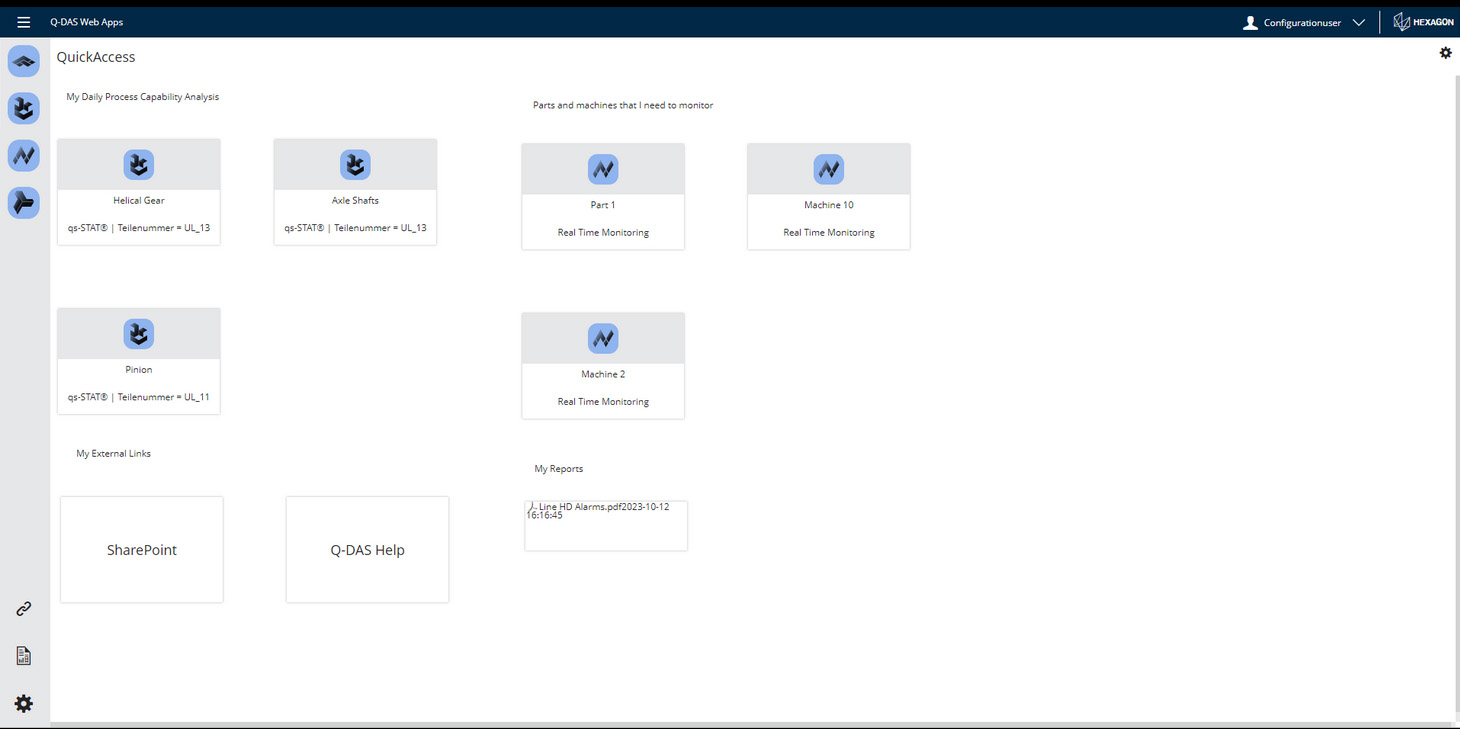

Q-DAS QuickAccess browser-based interface enhances the user experience

Are you tired of sifting through menus and endless clicks to access your favorite features?

Say goodbye to wasted time and frustration, and say hello to a smarter, faster, and more efficient way to use the Q-DAS Web product. Our QuickAccess interface is here to revolutionise your experience. It’s not just a feature, it’s a game-changer. Imagine having all your most-used functions and tools right at your fingertips, ready to go!

Benefit:

Users can access frequently used features or information quickly, improving the overall user experience. Reduces the time and effort required to perform common tasks, making the app more user-friendly. Personalisation: Users can customise the QuickAccess window to display the functions or content they use most, creating a tailored experience.

Q-DAS browser-based New Setup for multiple “Plants”

Revolutionise the way in which you manage the installation of Q-DAS Web for different production plants or departments. Manage all your plants from one place, to easily define all the different configurations, licenses and reports. Access real-time data anytime, anywhere within the company network.

Benefit:Possibility to conveniently segregate all your configurations and to quickly and easily define a “Test environment” for validation purposes, to streamline the configuration process for end users, and maximise efficiency.

-

Q-DAS 14.0.3

Reduce inspection time while maintaining high quality standards

Dynamic Inspection is a solution that helps customers reduce CMM inspection time in relation to the stability of their manufacturing process. Enabling customers to focus on the critical characteristics/ dimensions, with a 100% inspection while measuring the other features in a sequential and dynamic way, this would allow customers to reduce their inspection cycle time on the CMM drastically. In case of quality alarm, the incriminated characteristic or feature would be measured until reaches a phase of stability.

Benefit:

Reduction of cycle times.

Connected Quality data with ETQ interface

With the 14.0.3.1, Q-DAS offers a fluent integration with ETQ Quality Management System, to automate the NCR generation in case of quality alarms, ensuring full quality traceability in a collaborative environment to apply the right disposition for the incriminated parts and apply a long-term Corrective Action Preventive Action (CAPA) and powerful BI overview, to ensure the effectiveness and efficiency of your corrective actions and drastically reduce your quality costs.

Benefit:

Reduce quality and operating costs, reduce measurement bottlenecks, and improve your customers' satisfaction by ensuring on-time delivery and high-quality standards.

-

Q-DAS 14.0.2

New AI integration with automated time-series analysis and forecasting

With the implementation of this functionality, users of the Quality Assurance products get the ability to learn more about processes in terms of stability and potential tolerance deviations. With the forecast, they can act before real problems occur.

TSAF in Q-DAS qs-STAT

In qs-STAT there are two main functions - the 'Validation' and 'Forecast' mode:

In qs-STAT there are two main functions - the 'Validation' and 'Forecast' mode:

- With the Validation mode, the user can test and validate the accuracy of the forecasting on an existing set of measured values.

- In the Forecasting mode, the user can see predicted upcoming values to show the prediction uncertainty.

TSAF in Q-DAS M-QIS

Now in M-QIS users can define a reporting system job where they can apply TSAF evaluation to predict quality values when it predicts alarms it will automatically save a report on a specific location.

Benefits:

- Detect problems before they occur

- Initiate corrective actions in advance

- Ensure that process capability targets are met

- Achieve better process KPIs.

VDA 5 Enhancements

Combining uncertainty evaluation with gauge studies

In the new Q-DAS release 14.0.2., in Solara, it is possible to perform a VDA 5 study, bringing together an uncertainty-based approach, which involves uncertainty budgets and conformance limits, with the widely used Measurement Systems Analysis (MSA) procedures such as gauge R&R studies.

Implementation of Kendall’s evaluation

An additional feature has been implemented, the Kendall’s evaluation, to evaluate ordinal characteristics with a test decision with reference or without reference.

Benefit:

Higher accuracy for the evaluation of industrial measurements systems analysis.

EMPB -VDA2.6 PAPP

In the new Q-DAS version (14.0.2.1), an additional PPAP report templatehas been implemented in accordance with VDA volume 2 6th edition. Additional new changes have been made to improve the User Experience during the generation of these reports, and new fields have been added to allow the user to enter data in the PDF file.

Form designer enhancements

To increase the flexibility during the creation of new reports, new additional fields have been added in Form Designer, like the dropdown window where user can set a list of selection, checkbox to allow user to select an approval or rejection or result and a free text window for manual input of the users in the PDF reports.

Benefits:

- Time saving and cost reduction during the PAPP generation

- Improve resource allocation

- Adherence to VDA 2.6 standards.

Combines perfectly with other solutions from the Hexagon portfolio

The QA portfolio suits the target group of users from the field that already uses PC-DMIS and Quindos to measure on the CMM, where Q-DAS or eMMA can capture and store this data to validate the Measurement system and the production machine capability, monitor in real-time the process capability and with the new TSAF feature users can predict alarms and react before a process gets out of control.

-

Q-DAS 14.0.1

Customisation, usability, and performance enhancements give customers quicker access to and more control over how they interact with their data

Web-based enhancements:

Visualise your data the way you want to see it

Version 14 implements new ways to visualize data by allowing users to configure custom colors for alarms combined with more intuitive displays for instances where data is missing. Combined with clickable boxes for top-down navigation and general performance improvements, users can now more easily interpret their data.

Select and view the data you want, faster and easier

Version 14 gives customers more control over how they view and access their data. This includes the ability to set custom refresh cycle and customize basic graphic layouts to highlight what matters to you. It is also now easier to load machines and make custom field selections from your database, with the ability to store global and user-specific configurations for quicker recall.

Gain more control with full implementation of user and group management tools

The web application gains full support for user management with the latest release. Customers can now create, delete, edit users and groups, and manage system permissions all from the web application.

Access your preferred applications with extended short links

Users will notice improvements immediately upon opening the browser as we’ve added the ability to dive straight into their desired application, save preferred “start” application, and configure short links for quicker access to what matters most.

Desktop enhancements:

Expand your scope with support for even more standards and methodologies

- solara.MP adds extension to VDA 5 edition 3 This extension offers more accurate and fine evaluation of measurement uncertainty, easier definition and input of reference data details, direct import of type 1, type 2/3 in the measurement system and process masks, and increased usability.

- qs-STAT gains Anderson-Darling Test support in evaluation strategies This addition allows for integration in automatic evaluation, P-value as evaluation criterion, and includes graphics for displaying the characteristic values for the distribution classification or results of the test procedure.

Dive deeper into your data with new filter methods

The ability to create and utilize complex filters based on sub-selections allows users to fine tune data look ups using additional contextual filters form the selection result. New functions enable the ability to filter for alphanumeric data without even knowing the content.

Support for streaming technology offers more flexibility and saves time

With the new MQTT client integration, this release allows customers to take advantage of streaming technology for faster and more flexible access to their data.

Extend your data collection with support for more measurement devices

Q-DAS continues to add to its list of supported measurement devices with new interfaces for multiple types of devices, allowing customers to extend the value of their measurement data. -

eMMA 2024.2

eMMA MDM 2024.2

eMMA 3D Analyst

Feature label with individual diagrams per feature axis now with extended settings:

- Labels can generally be displayed vertically instead of horizontally

- Labels can be divided into individual diagrams per axis

- For individually positioned labels (pin mode), you can choose between horizontal and vertical alignment by simply clicking in the title bar of the label.

Extension of the “Histogram” display mode:

Up to 30 measurements can now be selected, a tooltip appears when a bar is selected and a configurable display of statistical parameters is possible via the settings menu

In the dialogue for sorting the measurements, individual entries can now be sorted manually using the arrow buttons

eMMA Server/Client

New function for automatic measurement plan update via control of a CATIA plug-in for updating the CAD models.

The input and results folders can be configured in the administrator client to connect the CATIA plug-in.

After activation, the “Update inspection plan” function is then available in the eMMA client.

This creates an order file with the part number and optionally the desired index in the inbox folder.

The system then waits with further processing until the MPA tool provides a CSV file in the results folder.

Finally, the standard template is copied and updated.

Import/Export

Interface to Quindos. Data from the metrology software can be exported directly to eMMA via an internal interface.

Support of „Alignments“ command in PC-DMIS-Stats file import. Alignments defined in PC-DMIS are now automatically transferred to eMMA.

First connection of the eMMA client with the Nexus application Metrology-Reporting

eMMA data can be transferred directly to Metrology Reporting in Nexus and visualized or used.

Nexus is Hexagon’s new Digital Reality Platform for manufacturers that connects people, technologies and data to accelerate innovation.

eMMA Fusion 2024.2

By entering the vehicle ID, it is possible to evaluate all quality information for the individual vehicle. The 3D information and its measurement results are loaded in order to be able to compare reality with the planning.

Datas from different part types for an assembly are summarized in one session and can be shared with the team. This enables more efficient collaboration.

There is a detailed view of the profile deviations based on the section, which can be defined interactively.

There is a detailed view of the profile deviations based on the section, which can be defined interactively.

-

eMMA 2024.1

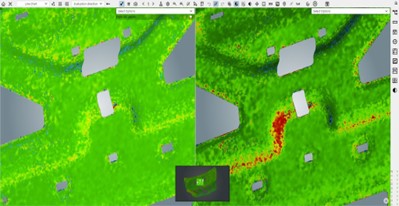

eMMA Fusion Side by Side View functionality.

Persona: Quality Engineer/ Quality Manager

Pain Point: In case of non-conformity, I need to analyze and compare the non-conformant part with others to see if there are correlations.

Solution: eMMA Fusion Side by Side View, allows users to easily compare two different parts or a single part with the aggregated results, e.g. the average, to easily find correlations or outliers.

eMMA Fusion Autoplay functionality.Persona: Inspector

Pain Point: Some parts have several dimensions and on different views, so sometimes it is difficult to find the right dimension on the CAD model and it is difficult to monitor it live with CAD model.

Solution: eMMA Fusion Autoplay function does allow users to monitor a specific part in Realtime with CAD model while changing views automatically.

eMMA Fusion Exaggeration View functionality.Persona: Quality Engineer/Quality Manager

Pain Point: On some measured optical data analysis is difficult to view the deviation.

Solution: eMMA Fusion Exaggeration function allows users to amplify the deviations to better identify quality non-conformities on the measured optical data, to easily detect and find all the deviations even on complex part.

eMMA Fusion Clipping Planes functionality.

Persona: Quality Engineer/ Quality Manager

Pain Point: Some dimensions or features are hidden, e.g. inside the CAD, which makes it difficult to analyze or report them.

Solution: eMMA Clipping Planes functionality allows you to easily create one or multiple sections of the CAD model to better analyze and report.

-

eMMA 3.5.1

New browser-based version eMMA Fusion opens up new opportunities for application

Revolutionise your data exploration with our groundbreaking 3D Data Analysis software. Navigate your assembly sequence from single parts to complete assemblies. Analyse optical and tactile measurements at the same time and for multiple parts.

For the first time, eMMA Fusion allows you to start your analysis immediately, with almost no setup time and little requirements. With a local installation, it is perfect for small projects with single-part or single-assembly products that need to be monitored and reported on.

Our advanced 3D view allows in-depth error analysis, real-time monitoring, and the generation of on-the-fly and customisable PDF reports. All directly on your CAD geometry. Identify problems where they appear and communicate them to your team. Use eMMA Fusion to access your data from any computer with no client installation. Create sessions and reports directly in your browser and share them with your team as easily as sending a link.

Our advanced 3D view allows in-depth error analysis, real-time monitoring, and the generation of on-the-fly and customisable PDF reports. All directly on your CAD geometry. Identify problems where they appear and communicate them to your team. Use eMMA Fusion to access your data from any computer with no client installation. Create sessions and reports directly in your browser and share them with your team as easily as sending a link.

Use eMMA Enterprise to prepare your inspection plans and assemble your finished products from single parts. Analyse them in-depth at every step of the way using our specialised modules. Create advanced virtual assemblies, align your components, and see the results in real time. In this environment, eMMA Fusion is your fast partner, available everywhere, to analyse and view your measurements, while our specialised modules allow for even more in-depth analysis.

Benefits:

- User-friendly: Simplify access, flattening the learning curve of users.

- Cost-effective: Save on IT resources and expenses associated with client installations, as browser-based applications reduce the need for individual device setups.

- Scalability: Suitable for businesses of all sizes, from small enterprises to large corporations.

-

eMMA 3.5.0

GD&T tolerances and result import make decisions easy

With the upcoming 3.5.0 release of eMMA, the actual feature location and an increasing number of GD&T feature types are now supported. The expansion of the list of GD&T feature types will help to extend the eMMA market to more industries that use many GD&T feature types, among others. High connectivity is ensured by the support of many formats, including the native PC-DMIS format DataPageStats-XML for the import of inspection plans and measurement results.

Benefit:

eMMA users now have the chance to import more types of GD&T features with their inspection plan for further analysis and monitoring.

-

eMMA 3.4.0

TSAF in Q-DAS eMMA

TSAF in Q-DAS eMMA

Q-DAS eMMA version 3.4.0. includes intelligence technology TSAF, specially tailored for the analysis of manufacturing data. The system learns from the previous measurements and gives an accurate prediction of the future trend of measurement results: automated, quick and accurate.

Benefits:

- Detect problems before they occur

- Initiate corrective actions in advance

- Ensure that process capability targets are met

- Achieve better process KPIs.

Combines perfectly with other solutions from the Hexagon portfolio

The QA portfolio suits the target group of users from the field that already uses PC-DMIS and Quindos to measure on the CMM, where Q-DAS or eMMA can capture and store this data to validate the Measurement system and the production machine capability, monitor in real-time the process capability and with the new TSAF feature users can predict alarms and react before a process gets out of control.