3D quality control of plastic parts

Contact us

The Wirthwein AG, a well-known German manufacturer of plastic components for the automotive, railway, electronics and home appliances industries as well as for medical science products, employs an AICON StereoScan in order to process the recorded 3D data of their components for evaluations with respect to geometry, shape and position tolerances and CAD comparisons.

Versatile applications for optical 3D metrology

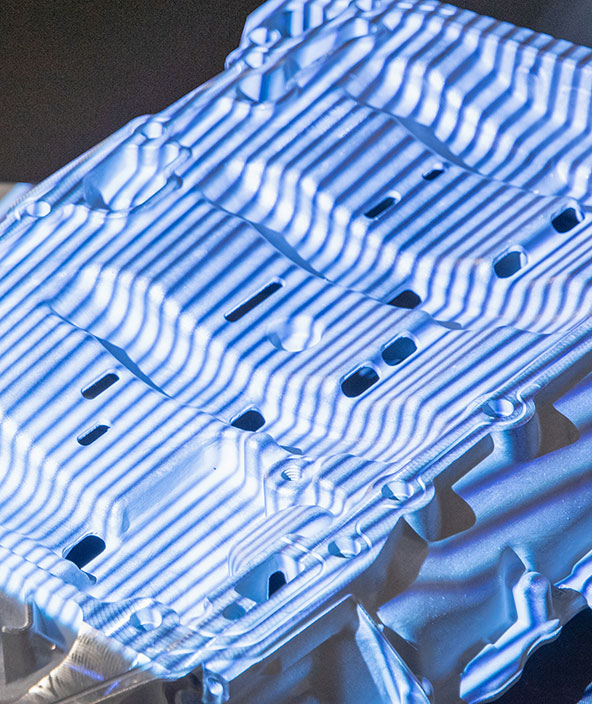

Application areas at Wirthwein range from first sample inspection and process optimization to random inline production quality inspection. Task of this particular project is to generate 3D measurement data of a component for a car door (200 x 140 x 30 mm) to be exported into a special 3D inspection software.

The object surface is semi-transparent, and in particular to capture the important “clips“ components at very high accuracy is a major requirement. The object exhibits a complex geometry with shading areas, undercuts and numerous edges which pose a particular difficulty to conventional digitisation systems.

Given the demanding requirements with regard to resolution, feature accuracy and flexibility combined with the demand to simultaneously scan areas which are difficult to access from three different triangulation angles, Wirthwein decided in favor of the AICON StereoScan. To achieve a virtually automated digitisation process, the scanner is combined with a turntable (available as optional accessory).

Less time and effort thanks to automation

To achieve a virtually automated digitisation process, the scanner is combined with a turntable. In the AICON StereoScan, two color cameras are used for this project, each with a resolution of 5 megapixel. This system setup achieves an accuracy of ±10 µm.

The workflow in detail:

1. Digitisation and data evaluation

- Using a turntable, the measuring process is (semi-) automated

- Digital three-dimensional measurement of the object with the StereoScan

- Calculation of the object geometry and visualization

- Transfer of the 3D data to the inspection software

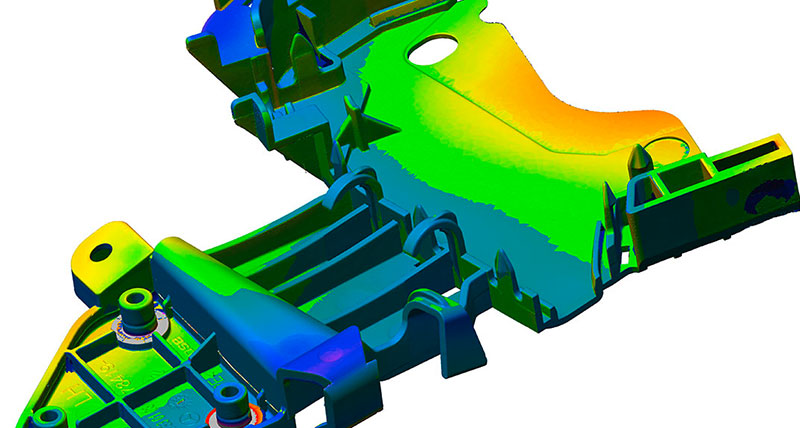

2. Inspection with Polyworks/InspectorTM

- Import of the CAD reference data

- Definition of inspection criteria based on the CAD model (to be carried out once): trimming lines, relative surface reference points, specific features of drilling holes, studs, clips and plains, position reference, diameter, parallelism, rectangularity, etc.

- Loading the scan data

- Automatic alignment and automatic inspection process including measurement reports and archiving

- Freely configurable visualization of the quality inspection result through false color representation in 2D and 3D, tables with nominal values and tolerances, cuts, etc.

Increased quality standard

Using state of the art optical 3D inspection technology of the AICON StereoScan system in combination with a turntable and a powerful inspection software enables Wirthwein to perform automated, three-dimensional quality inspection of their plastic parts and components.

An efficient and reliable inspection flow is ensured despite processing vast data volumes as result of the holistic inspection approach. The measurement evaluation results are directly fed back into the manufacturing process, thus adding immediate benefit to the production efficiency, and in the final result ensuring the high quality standard of all automobiles equipped with Wirthwein plastic components.

We would like to thank the employees of the company Wirthwein for their cooperation and support in creating this report.