Hexagon Split: Closing the drill and blast gap

Learn more about how Split Engineering helps expand Hexagon’s life-of-mine vision from pit to plant and closes the loop on drill and blast design.

Manage fragmentation from blast to mill with the most technologically advanced image-analysis techniques used by mines worldwide and based on more than 25 years of research and development.

Optimize fragmentation with an integrated blast-to-mill suite and save your mine significant costs while improving drill and blast processes.

Hexagon Split’s image processing technology delivers high-quality information that enables you to manage your processes from drill to mill and improve mine profits.

Immediate feedback to the mine on blast performance; feed forward to the plant on what is coming from the mine; correlation of PSD to shovel maintenance and enhanced process control decisions; the only place to measure run-of-mine leach ore.

Automatic and real-time feedback to the mine on blast performance; feed forward to the plant on what is coming from the mine; correlation of PSD to operational performance and enhanced process control decisions.

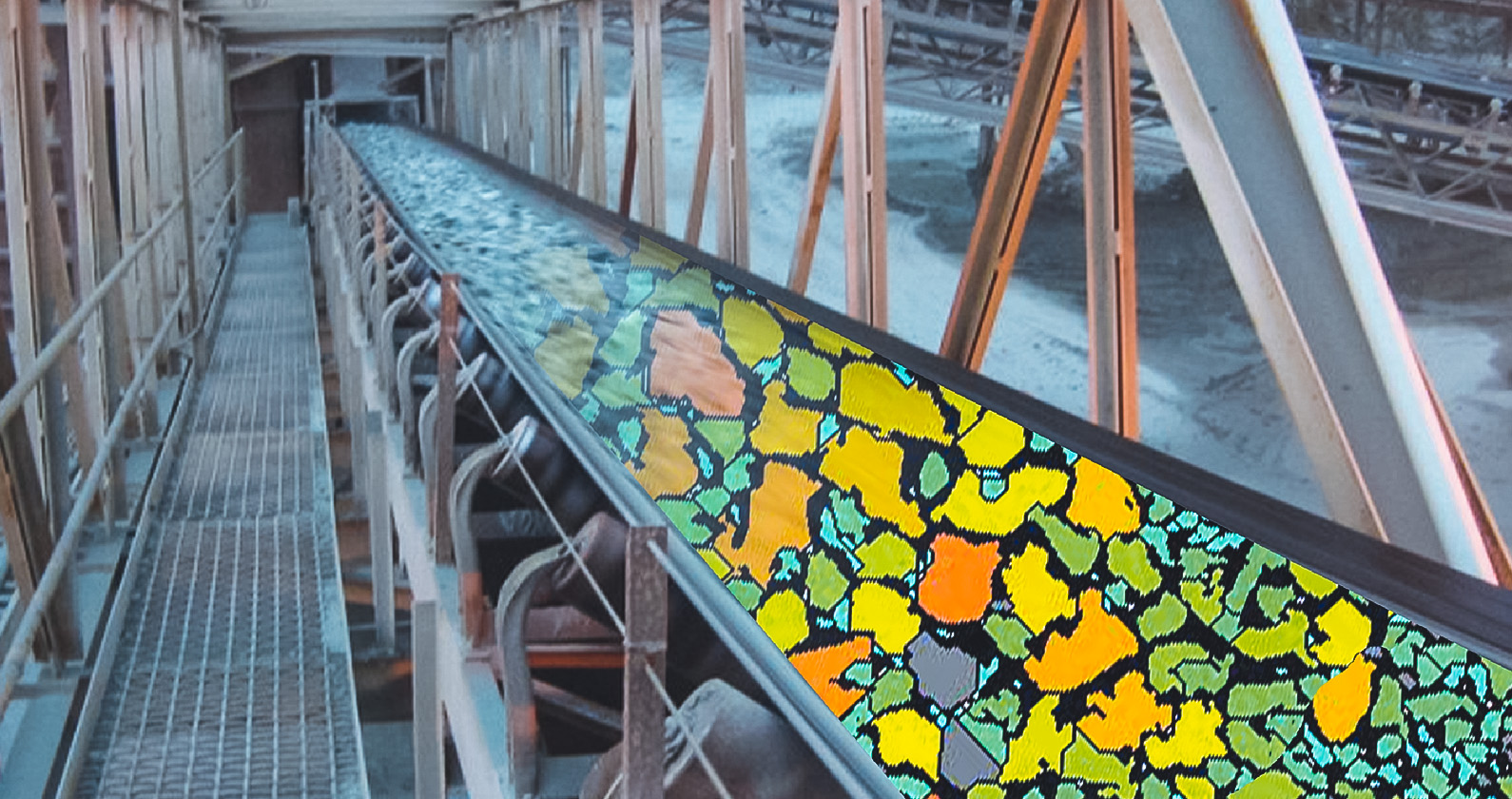

Continuous, automatic, non-invasive monitoring system employing image processing technology for particle size, shape and color for any conveyor belt or feeder location. Immediate feedback to crushing, screening, and milling in the comminution circuit.

Learn more about how Split Engineering helps expand Hexagon’s life-of-mine vision from pit to plant and closes the loop on drill and blast design.

In our case study, learn how two Peruvian copper mines used Hexagon Split to maximize monthly profits with fragmentation analysis after recognizing the need to invest in drill and blast operations.

In our software and service overview brochure, learn more about Hexagon Split products: Split-ShovelCam, Split-TruckCam, Split Conveyor-Cam, Split-Net, Split-FX and Split Desktop.

In our video, see how Hexagon Split’s image processing technology delivers high-quality information that enables you to manage your processes from drill to mill and improve mine profits.