Installation Services

An effective sensor installation considers not only mounting and connecting the sensors but also providing a highly reliable means of transmitting sensor data to your workflow.

Unlock sensor integration

Beyond mounting and connectivity, ensure reliable sensor data transmission to optimize your workflows

Streamlining sensor data collection

Maximize efficiency and accuracy with diverse sensor installations and advanced data collection methods.

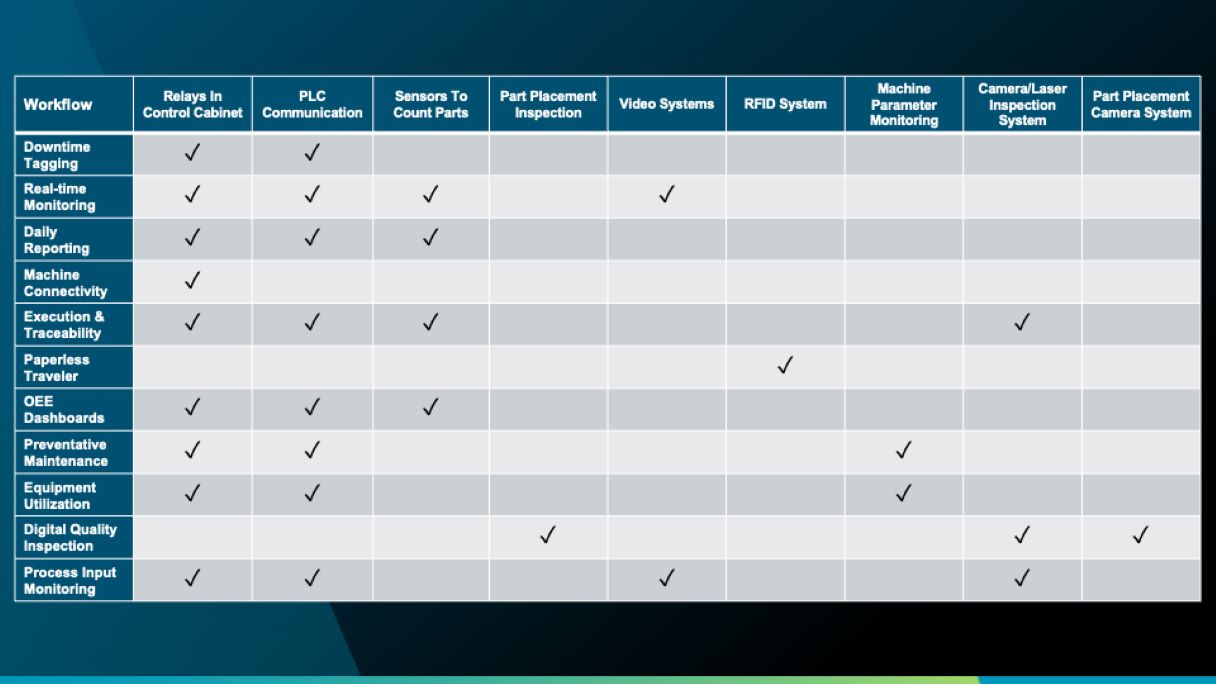

An effective sensor installation goes beyond mere mounting and connection; it ensures a flow of data to empower your workflow. From simple endpoints for basic data sampling to advanced PLC systems for high-throughput equipment, we offer comprehensive solutions tailored to your needs.

By interfacing directly with your machine controllers, we gauge throughput and uptime/downtime, providing insights into equipment cycles, operational status, and reasons for downtime. Even for legacy equipment lacking PLCs, we install relays to monitor machine cycles and operational status, ensuring uninterrupted data collection.

Our sensor installations cover a wide array of applications, including conveyor systems, machine cycle counting, and assembly tracking, all integrated into your existing infrastructure. Whether leveraging existing 120V and Ethernet drops or integrating new power and network lines, we ensure uninterrupted sensor data availability, even during maintenance shutdowns.

Even in challenging conditions, our sensors deliver reliable and accurate data, thanks to precise adjustments and tuning. Whether it's irregularly shaped products or translucent materials causing multiple counts, our sensors adapt, ensuring precise measurements every time.

With our expertise, we analyze complex conveyor paths, determining optimal sensor locations and aggregating data to support all paths without complex logic. Additionally, we offer specialized mounting solutions for sensors inside equipment, ensuring accurate measurement of production flow with precision positioning, special brackets, and specific settings.

Installation steps

Nexus Connected Worker Hardware + Software