How to bring an aged train spare part in shape for additive manufacturing with generative design

Reduce additive production costs with customized, weight-optimised designs and produce spare parts flexibly and without tools

Adapted design for 3D printed spare parts

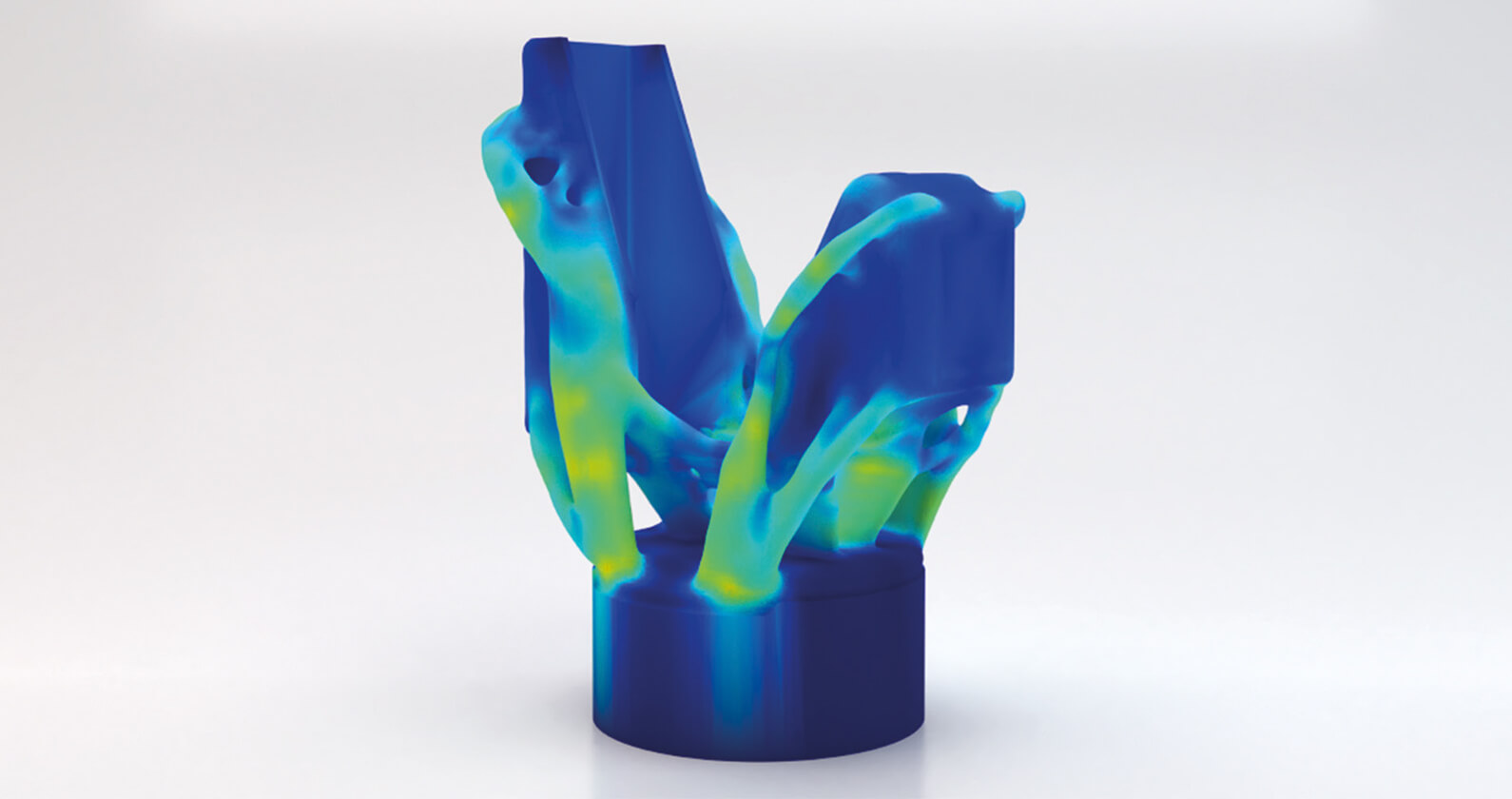

Re-engineering and optimisation of a conventionally designed hinge of a cargo wagon for additive manufacturing spare part production

Assets such as freight cars are characterized by a service life of several decades. When defects occur in the assets, the procurement of spare parts poses major challenges for operators with extremely long lead times and high costs. With additive manufacturing, there is now the possibility of producing spare parts without tools and thus in a highly flexible manner. However, the conventional designs themselves are also problematic, as they are difficult or impossible to manufacture with additive manufacturing. Here, the weight-optimised result from MSC Apex Generative Design can help to enable a cost-efficient production through 3D printing.

Read now how Generative Design supports the quick and easy redesign for 3D printing!