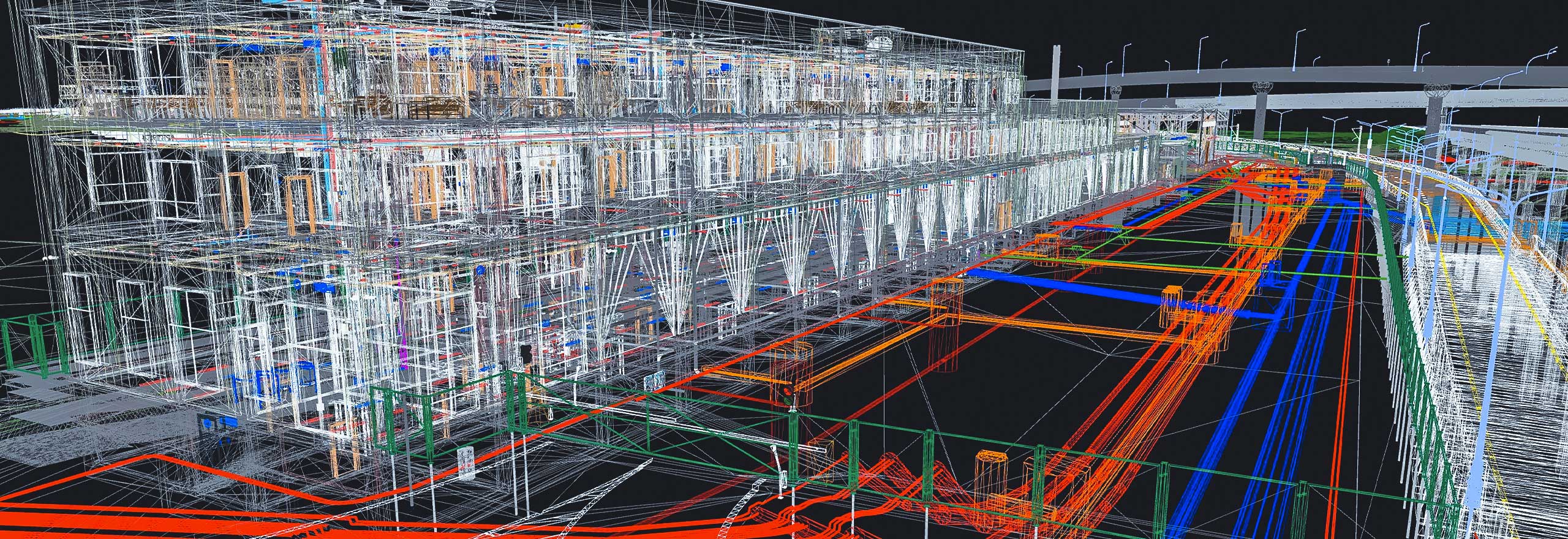

Modelo 3D de visualización de activos de ingeniería

Sus proyectos y datos de O&M forjados en un activo digital inteligente para un rendimiento empresarial superior.

¿Quiere saber más?

Datos a lo largo del ciclo de vida del activo

-

Overview

-

For projects

-

For operations and maintenance

Digital realities for engineering assets

The volume of information created today is greater than at any other time in human history—and only a mere percentage of that data is ever used. For large, industrial assets, siloed data across many disciplines creates inefficiencies and encourages poor performance. To counter this, industry leaders are transforming their businesses to create digital twins connected by a digital threadDigital twins

Digital twins and their models are synced with their physical twin throughout service life to enable previously unattainable critical insights to help you understand the “what” and the “why”.The digital thread

The digital thread provides a means to navigate between the various digital twins used throughout the asset lifecycle to help you understand the “intent” behind the design, strategy and/or process. At Hexagon, we help our customers with the tools to create digital twins and provide the digital backbone that weaves all of the data sources into the connected digital thread.

Engineering and construction of industrial assets involves an incredible coordination effort of teams, resources and tools. As the technology advances, so do the possibilities—a single pane of glass view of every project, and all the data that makes up that project—from 2D and 3D designs, cost and schedule information, materials management and all the elements to be packaged and delivered as a digital twin to the asset owner at handover.

Hexagon asset visualisation helps create and maximise the value of the digital thread throughout the asset lifecycle. Consider these project benefits:

- Reduced process design time

- Lower CapEx for project design and execution

- Improved design review efficiency

- Decreased design errors

- Reduced project mobilisation costs

- Declining project handover efforts

Today, asset owners have a huge amount of data available—performance and telemetry—but is it being utilised to its fullest?

Consider a drive towards predictive maintenance over fixed maintenance schedules. Artificial intelligence can automatically convert a laser scan of an existing facility into a fully-tagged engineering document.

Hexagon customers can maximise the value of their digital tread throughout the asset lifecycle in many ways including:

- Reduced maintenance costs

- Enhanced situational awareness

- Improved regulatory compliance

- Better workforce productivity

- More production capacity

- Decreased inventory carrying costs

- Overview

Digital realities for engineering assets

The volume of information created today is greater than at any other time in human history—and only a mere percentage of that data is ever used. For large, industrial assets, siloed data across many disciplines creates inefficiencies and encourages poor performance. To counter this, industry leaders are transforming their businesses to create digital twins connected by a digital threadDigital twins

Digital twins and their models are synced with their physical twin throughout service life to enable previously unattainable critical insights to help you understand the “what” and the “why”.The digital thread

The digital thread provides a means to navigate between the various digital twins used throughout the asset lifecycle to help you understand the “intent” behind the design, strategy and/or process. At Hexagon, we help our customers with the tools to create digital twins and provide the digital backbone that weaves all of the data sources into the connected digital thread.

- For projects

Engineering and construction of industrial assets involves an incredible coordination effort of teams, resources and tools. As the technology advances, so do the possibilities—a single pane of glass view of every project, and all the data that makes up that project—from 2D and 3D designs, cost and schedule information, materials management and all the elements to be packaged and delivered as a digital twin to the asset owner at handover.

Hexagon asset visualisation helps create and maximise the value of the digital thread throughout the asset lifecycle. Consider these project benefits:

- Reduced process design time

- Lower CapEx for project design and execution

- Improved design review efficiency

- Decreased design errors

- Reduced project mobilisation costs

- Declining project handover efforts

- For operations and maintenance

Today, asset owners have a huge amount of data available—performance and telemetry—but is it being utilised to its fullest?

Consider a drive towards predictive maintenance over fixed maintenance schedules. Artificial intelligence can automatically convert a laser scan of an existing facility into a fully-tagged engineering document.

Hexagon customers can maximise the value of their digital tread throughout the asset lifecycle in many ways including:

- Reduced maintenance costs

- Enhanced situational awareness

- Improved regulatory compliance

- Better workforce productivity

- More production capacity

- Decreased inventory carrying costs

Explorar

Nuestras soluciones para la gestión de proyectos de planta ayudan a evitar los gastos derivados tanto del exceso como de la escasez, así como a reducir el riesgo general del proyecto.

DestacadosProducto

DestacadosProductoIntergraph Smart® Completions consolida la información de los activos y verifica la instalación, las pruebas y el rendimiento de los equipos.

-

×Parcial autonomyRecopilación automática de paquetes de volumen de ventas con asignación automática de inspecciones, listas de perforación y certificados

-

Producto

ProductoIntergraph Smart® Construction es un software de gestión que ayuda a planificar y gestionar proyectos de fabricación y construcción.

-

×Con asistencia humana autonomyFlujos de trabajo automatizados diseñados específicamente para mejorar las operaciones eficientes con materiales

-

Producto

ProductoIntergraph Smart® Materials es una solución de software integrada para la gestión integral de materiales.

-

×Con asistencia humana autonomyFlujos de trabajo automatizados diseñados específicamente para mejorar las operaciones eficientes con materiales

-

Producto

ProductoIntergraph Smart® Production cuenta con un enfoque ascendente para controlar el proceso de producción basado en conceptos de la Industria 4.0.

-

×Con asistencia humana autonomyFlujos de trabajo automatizados diseñados específicamente para mejorar las operaciones eficientes con materiales

-

El entorno 3D inteligente permite un diseño y una ingeniería de planta sin silos y con mayor dinamismo, colaboración y menos tiempo para la comercialización.

Producto

ProductoIntergraph Smart® Review es el entorno de visualización para revisar y analizar de forma interactiva modelos 3D grandes y complejos.

-

×Con asistencia humana autonomyCapacidades automatizadas que ayudan a maximizar la eficiencia y reducir los errores

-