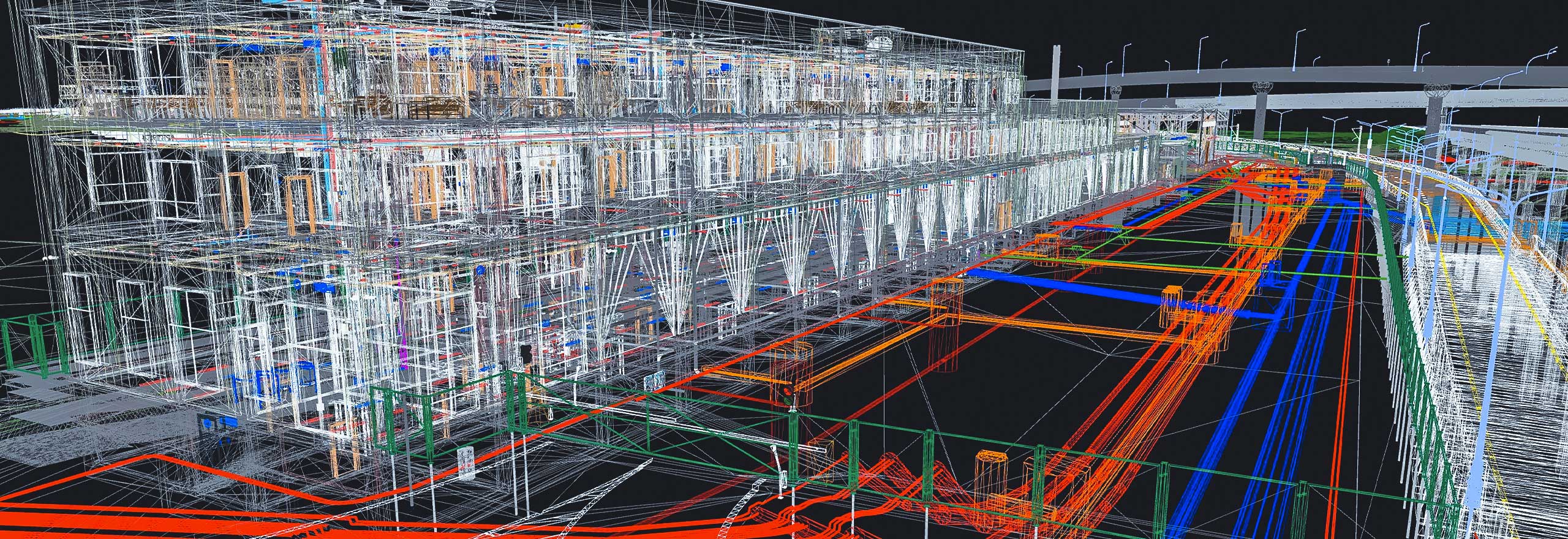

Model 3D Visualisasi Aset Perekayasaan

Data proyek dan O&M Anda ditempa dalam aset digital pintar untuk kinerja bisnis yang unggul.

Siap untuk mempelajari selengkapnya?

Data atas siklus hidup aset

-

Overview

-

For projects

-

For operations and maintenance

Digital realities for engineering assets

The volume of information created today is greater than at any other time in human history—and only a mere percentage of that data is ever used. For large, industrial assets, siloed data across many disciplines creates inefficiencies and encourages poor performance. To counter this, industry leaders are transforming their businesses to create digital twins connected by a digital threadDigital twins

Digital twins and their models are synced with their physical twin throughout service life to enable previously unattainable critical insights to help you understand the “what” and the “why”.The digital thread

The digital thread provides a means to navigate between the various digital twins used throughout the asset lifecycle to help you understand the “intent” behind the design, strategy and/or process. At Hexagon, we help our customers with the tools to create digital twins and provide the digital backbone that weaves all of the data sources into the connected digital thread.

Engineering and construction of industrial assets involves an incredible coordination effort of teams, resources and tools. As the technology advances, so do the possibilities—a single pane of glass view of every project, and all the data that makes up that project—from 2D and 3D designs, cost and schedule information, materials management and all the elements to be packaged and delivered as a digital twin to the asset owner at handover.

Hexagon asset visualisation helps create and maximise the value of the digital thread throughout the asset lifecycle. Consider these project benefits:

- Reduced process design time

- Lower CapEx for project design and execution

- Improved design review efficiency

- Decreased design errors

- Reduced project mobilisation costs

- Declining project handover efforts

Today, asset owners have a huge amount of data available—performance and telemetry—but is it being utilised to its fullest?

Consider a drive towards predictive maintenance over fixed maintenance schedules. Artificial intelligence can automatically convert a laser scan of an existing facility into a fully-tagged engineering document.

Hexagon customers can maximise the value of their digital tread throughout the asset lifecycle in many ways including:

- Reduced maintenance costs

- Enhanced situational awareness

- Improved regulatory compliance

- Better workforce productivity

- More production capacity

- Decreased inventory carrying costs

- Overview

Digital realities for engineering assets

The volume of information created today is greater than at any other time in human history—and only a mere percentage of that data is ever used. For large, industrial assets, siloed data across many disciplines creates inefficiencies and encourages poor performance. To counter this, industry leaders are transforming their businesses to create digital twins connected by a digital threadDigital twins

Digital twins and their models are synced with their physical twin throughout service life to enable previously unattainable critical insights to help you understand the “what” and the “why”.The digital thread

The digital thread provides a means to navigate between the various digital twins used throughout the asset lifecycle to help you understand the “intent” behind the design, strategy and/or process. At Hexagon, we help our customers with the tools to create digital twins and provide the digital backbone that weaves all of the data sources into the connected digital thread.

- For projects

Engineering and construction of industrial assets involves an incredible coordination effort of teams, resources and tools. As the technology advances, so do the possibilities—a single pane of glass view of every project, and all the data that makes up that project—from 2D and 3D designs, cost and schedule information, materials management and all the elements to be packaged and delivered as a digital twin to the asset owner at handover.

Hexagon asset visualisation helps create and maximise the value of the digital thread throughout the asset lifecycle. Consider these project benefits:

- Reduced process design time

- Lower CapEx for project design and execution

- Improved design review efficiency

- Decreased design errors

- Reduced project mobilisation costs

- Declining project handover efforts

- For operations and maintenance

Today, asset owners have a huge amount of data available—performance and telemetry—but is it being utilised to its fullest?

Consider a drive towards predictive maintenance over fixed maintenance schedules. Artificial intelligence can automatically convert a laser scan of an existing facility into a fully-tagged engineering document.

Hexagon customers can maximise the value of their digital tread throughout the asset lifecycle in many ways including:

- Reduced maintenance costs

- Enhanced situational awareness

- Improved regulatory compliance

- Better workforce productivity

- More production capacity

- Decreased inventory carrying costs

Telusuri

Lingkungan 3D yang cerdas memungkinkan desain dan perekayasaan pabrik yang bebas pengkotak-kotakan, kolaborasi, dan mengurangi time to market.

Product

ProductIntergraph Smart® Review is the visualisation environment for interactively reviewing and analysing large, complex 3D models.

-

×Human-Assisted autonomyAutomated capabilities that assist with maximizing efficiency and reducing errors

-

Solusi manajemen proyek pabrik dari kami membantu menghindari kelebihan dan kekurangan yang berbiaya mahal, serta mengurangi risiko proyek secara keseluruhan.

FeaturedProduct

FeaturedProductIntergraph Smart® Completions consolidates asset information and verifies equipment installation, testing and performances.

-

×Partial autonomyAutomatic compilation of turnover packages with auto assignment of inspections, punch lists, and certificates

-

Product

ProductIntergraph Smart® Construction is management software that helps plan and manage fabrication and construction projects.

-

×Human-Assisted autonomyAutomated workflows specifically designed to inprove efficient material operations

-

Product

ProductIntergraph Smart® Materials is an integrated software solution for end-to-end materials management.

-

×Human-Assisted autonomyAutomated workflows specifically designed to inprove efficient material operations

-

Product

ProductIntergraph Smart® Production features a bottom-up approach to control the production process based on Industry 4.0 concepts.

-

×Human-Assisted autonomyAutomated workflows specifically designed to inprove efficient material operations

-