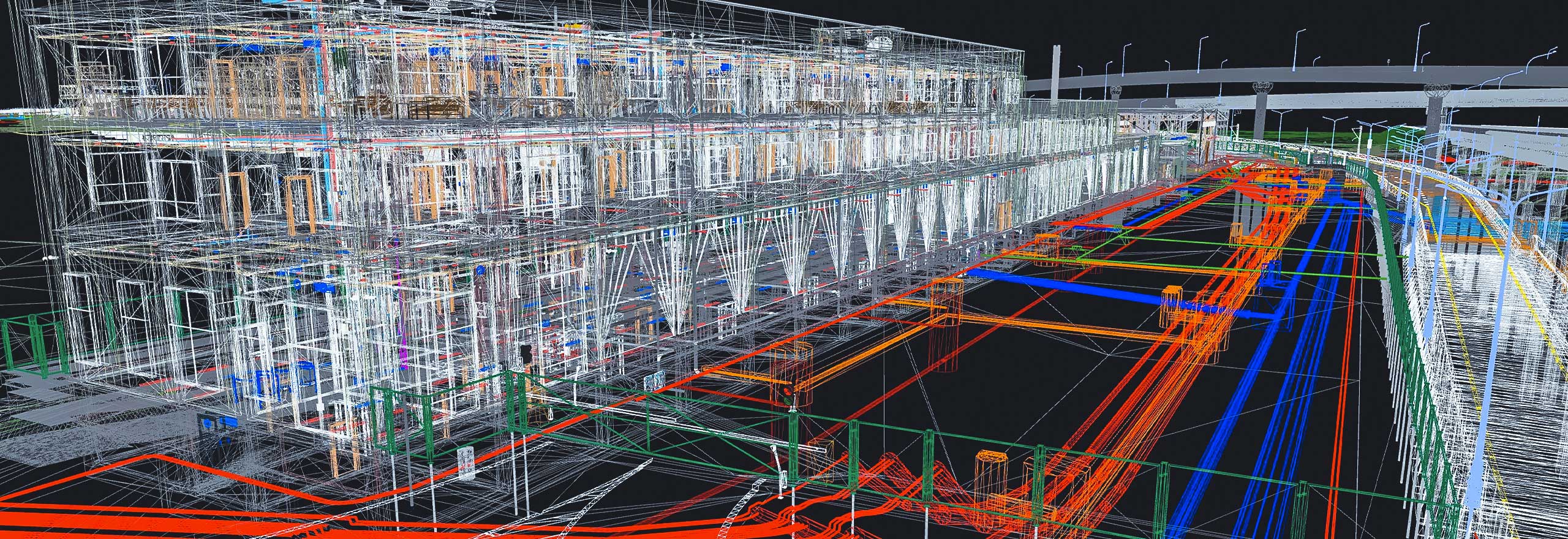

엔지니어링 자산 시각화 3D 모델

이제 프로젝트 및 O&M 데이터가 뛰어난 비즈니스 성과를 달성하기 위한 스마트 디지털 자산으로 바뀝니다.

자세한 내용을 확인해 보시겠습니까?

자산 라이프사이클 동안의 데이터

-

Overview

-

For projects

-

For operations and maintenance

Digital realities for engineering assets

The volume of information created today is greater than at any other time in human history—and only a mere percentage of that data is ever used. For large, industrial assets, siloed data across many disciplines creates inefficiencies and encourages poor performance. To counter this, industry leaders are transforming their businesses to create digital twins connected by a digital threadDigital twins

Digital twins and their models are synced with their physical twin throughout service life to enable previously unattainable critical insights to help you understand the “what” and the “why”.The digital thread

The digital thread provides a means to navigate between the various digital twins used throughout the asset lifecycle to help you understand the “intent” behind the design, strategy and/or process. At Hexagon, we help our customers with the tools to create digital twins and provide the digital backbone that weaves all of the data sources into the connected digital thread.

Engineering and construction of industrial assets involves an incredible coordination effort of teams, resources and tools. As the technology advances, so do the possibilities—a single pane of glass view of every project, and all the data that makes up that project—from 2D and 3D designs, cost and schedule information, materials management and all the elements to be packaged and delivered as a digital twin to the asset owner at handover.

Hexagon asset visualisation helps create and maximise the value of the digital thread throughout the asset lifecycle. Consider these project benefits:

- Reduced process design time

- Lower CapEx for project design and execution

- Improved design review efficiency

- Decreased design errors

- Reduced project mobilisation costs

- Declining project handover efforts

Today, asset owners have a huge amount of data available—performance and telemetry—but is it being utilised to its fullest?

Consider a drive towards predictive maintenance over fixed maintenance schedules. Artificial intelligence can automatically convert a laser scan of an existing facility into a fully-tagged engineering document.

Hexagon customers can maximise the value of their digital tread throughout the asset lifecycle in many ways including:

- Reduced maintenance costs

- Enhanced situational awareness

- Improved regulatory compliance

- Better workforce productivity

- More production capacity

- Decreased inventory carrying costs

살펴보기

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.