Абсолютный трекер: Автоматизированное производство

Автоматизированное производство с непревзойденной точностью

Свяжитесь с нами

Основанные на опыте использования приложений в области автоматизированного контроля, наши решения Laser Tracker Automation прокладывают путь к настоящей сборке с метрологической поддержкой. Внедрение современных измерительных средств непосредственно в процесс управления производством - это следующий шаг на пути к действительно «умному» производству.

7DoF с AT960

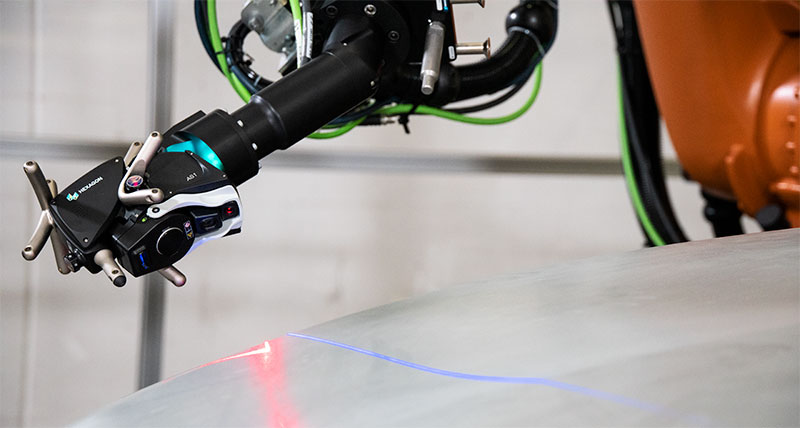

Системы автоматизированного управления производством основаны на возможностях трекера Leica Absolute Tracker AT960 измерять в шести степенях свободы (6DoF), что позволяет точно отслеживать и ориентировать датчик внутри измерительного объема до 60 метров в диаметре.

С добавлением пакета функций реального времени (RTFP) AT960 становится системой, отвечающей требованиям получения детерминированных данных измерений для оперативного управления робототехническими устройствами. Основанный на проверенном протоколе EtherCat, пакет RTFP позволяет получать данные измерений 6DoF с точными отметками времени с выходной частотой до 1000 Гц - так называемые данные измерения 7DoF.

Благодаря такому датчику как Leica T-Mac, устанавливаемому непосредственно на месте производства, трекер AT960, дополненный пакетом RTFP, может обеспечить точный контроль в системах, включающих такие процессы, как механическая обработка, сборка деталей или любая другая производственная деятельность, управляемая роботом, для которых точность очень важна.

Эта автоматизированная технология, основанная на использовании лазерных трекеров, обладает возможностью достигать непревзойденных уровней точности в самом центре производственного процесса, контролируя качество детали непосредственно в ходе, а не после ее изготовления. Это означает меньший объем отходов, меньшие затраты времени и более высокое качество продукции.

С добавлением пакета функций реального времени (RTFP) AT960 становится системой, отвечающей требованиям получения детерминированных данных измерений для оперативного управления робототехническими устройствами. Основанный на проверенном протоколе EtherCat, пакет RTFP позволяет получать данные измерений 6DoF с точными отметками времени с выходной частотой до 1000 Гц - так называемые данные измерения 7DoF.

Благодаря такому датчику как Leica T-Mac, устанавливаемому непосредственно на месте производства, трекер AT960, дополненный пакетом RTFP, может обеспечить точный контроль в системах, включающих такие процессы, как механическая обработка, сборка деталей или любая другая производственная деятельность, управляемая роботом, для которых точность очень важна.

Эта автоматизированная технология, основанная на использовании лазерных трекеров, обладает возможностью достигать непревзойденных уровней точности в самом центре производственного процесса, контролируя качество детали непосредственно в ходе, а не после ее изготовления. Это означает меньший объем отходов, меньшие затраты времени и более высокое качество продукции.

Leica Absolute Tracker AT960 7DoF Explained

Чувствовать-думать-действовать: 7DoF-функция Leica Absolute Tracker AT960. Корректировка в реальном времени автоматизированных крупносерийных производственных приложений с помощью технологии лазерного трекера.