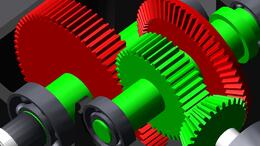

Adams machinery

기계적인 구동 시스템에 적합한 강력한 시뮬레이션 제품군

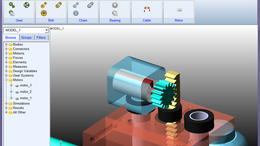

성능, 안전성, 쾌적함이 향상된 설계 개선안을 도출하기 위한 운동, 구조, 구동 제어 등이 연계된 복잡한 시스템에 대한 평가 및 관리 가능

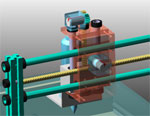

설계 초기단계에서 기계 부품 및 시스템에 대한 가상 시제품을 구축해, 물리적인 시제품을 만들기 이전에 다양한 가상의 시험을 수행할 수 있습니다. 이러한 새로운 솔루션을 통해서, 기계 제조업체는 시제품의 숫자를 줄이고, 설계 기간을 단축하고 목표 성능을 달성하는 시간을 단축할 수 있게 됩니다.

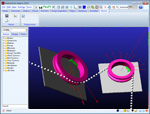

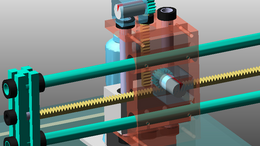

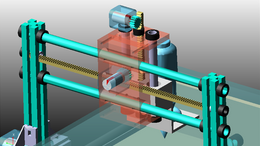

Adams/Machinery는 Adams/View 환경에 완전히 통합됩니다. 다양한 생성 모듈들을 포함하고 있어서 Adams/View의 표준 기능만을 이용해 기능을 구현할 때보다 훨씬 빠른 시간 내에 기계 부품에 대한 모델을 생성할 수 있습니다.

사용의 편리성

Adams의 리본메뉴 환경과 모델 브라우저는 비숙련 해석자의 경우에도 완전하고 정교한 기계적인 모델을 쉽게 생성할 수 있도록 돕습니다. 핵심 패키지 (Adams/View, Adams/Solver, and Adams/PostProcessor)는 대부분의 주요 CAD 시스템으로부터 모양을 가져올 수 있고, 기계 시스템의 솔리드 모델을 처음부터 구축할 수 있습니다. 시스템의 구축 방법도 실제 시스템의 경우와 동일합니다. 즉, 부품을 만들어 조립하고 그것을 연결형상에 맞추어서 연결하고 움직임을 정의하는 힘을 가하여 가상의 시스템을 생성합니다.

높은 생산성

Adams/Machinery는 자동 형상 생성이나 서브시스템 연결 등의 전처리를 통해서 효율적으로 사용자를 안내해 일반적인 기계 부품을 효율적으로 생성할 수 있게 도와줍니다. 또한, 사용자가 필요한 자동화된 그래프 생성이나 보고서 작성 등의 후처리 기능을 통해 생산성을 향상시켜줍니다.

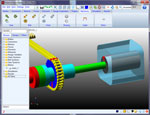

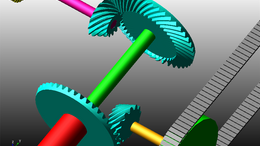

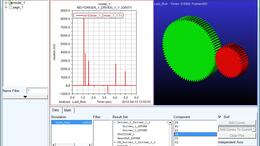

The Adams model has subsequently been used to perform an extensive parameter study to find the root cause and solutions to the observed gear resonance.”

- Christina Exner Manager, Achates Power

-

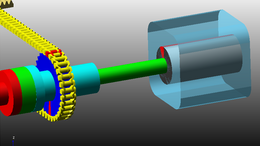

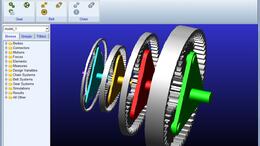

Gears module

-

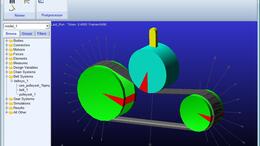

Belts module

-

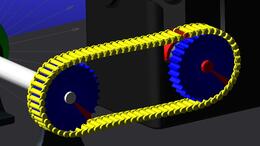

Chains module

-

Bearings module

-

Cable module

-

Electric motors module

-

Cam module

-

-