Measurement of rotor and stator laminations for electric vehicle motors

Optical measurement solutions for electric vehicle motors’ rotor and stator sheet metal cuts

Contato

As the drive towards eMobility continues, the requirements for electric vehicle drives are changing. The goal for manufacturers is to optimise the electric motor in terms of efficiency, quality and costs. New motor concepts are needed and lamination stacks for rotors and stators are of particular importance, as they have a decisive influence on the efficiency an electric motor can achieve. The rotor and stator stacks are usually composed of individual laminations. New production engineering approaches, such as segmented lamination packages that are subsequently assembled to form a solid rotor or stator, require optical metrology to alongside the production process to meet the changing requirements.

During production of the individual laminations, tight tolerances must be maintained with high repeatability to ensure the optimum connection to the lamination stack, providing the required electrical, magnetic and mechanical properties. The positioning of a sheet metal part like a rotor or stator lamination in the working volume of the gauge can be either manual or run automatically as a best-fit alignment. The dimensional, form and positional tolerances of punched holes in the sheet metal lamellae must be checked using 2D vision inspection, while a contour scan mode can evaluate sheet metal cuts as a line shape.

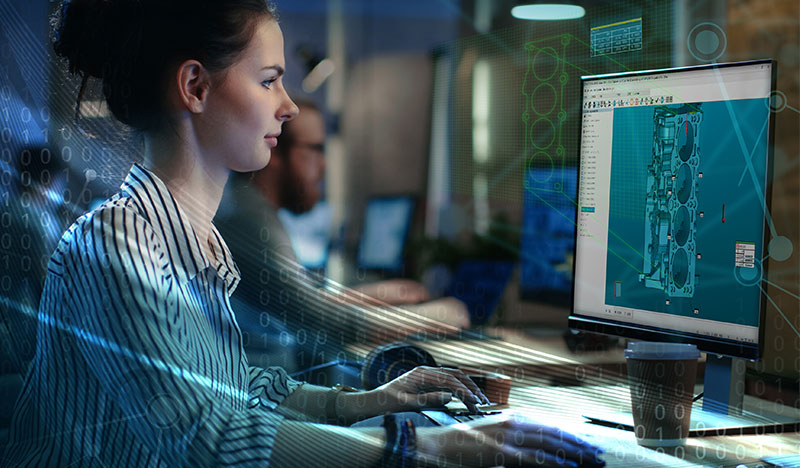

For sheet metal inspections such as rotor and stator lamination measurement, a measuring device that can process as many parts as possible within an automated routine offers considerable time saving potential. Multisensor coordinate measuring machines (CMMs) therefore offer the most practical solution for documenting the produced quality during production. By palletising large batches of sheet metal parts, fast, automated inspection routines can be achieved to capture all necessary dimensional measurements.

With the support of the right software solution, high throughput can be achieved with accurate and reliable results in pallet measurements. A metrology software that supports CAD enables the relevant dimensional and tolerance data to be automatically extracted from the imported drawing during the creation of the measurement routine, minimising the possibility of input and interpretation errors. The sheet metal cut contours captured by the vision sensor in scan mode can then be compared with the 2D CAD data to evaluate shape and position characteristics. Software that supports palletised measurement can also be useful for inspecting large batches of rotor and stator lamination.

During production of the individual laminations, tight tolerances must be maintained with high repeatability to ensure the optimum connection to the lamination stack, providing the required electrical, magnetic and mechanical properties. The positioning of a sheet metal part like a rotor or stator lamination in the working volume of the gauge can be either manual or run automatically as a best-fit alignment. The dimensional, form and positional tolerances of punched holes in the sheet metal lamellae must be checked using 2D vision inspection, while a contour scan mode can evaluate sheet metal cuts as a line shape.

For sheet metal inspections such as rotor and stator lamination measurement, a measuring device that can process as many parts as possible within an automated routine offers considerable time saving potential. Multisensor coordinate measuring machines (CMMs) therefore offer the most practical solution for documenting the produced quality during production. By palletising large batches of sheet metal parts, fast, automated inspection routines can be achieved to capture all necessary dimensional measurements.

With the support of the right software solution, high throughput can be achieved with accurate and reliable results in pallet measurements. A metrology software that supports CAD enables the relevant dimensional and tolerance data to be automatically extracted from the imported drawing during the creation of the measurement routine, minimising the possibility of input and interpretation errors. The sheet metal cut contours captured by the vision sensor in scan mode can then be compared with the 2D CAD data to evaluate shape and position characteristics. Software that supports palletised measurement can also be useful for inspecting large batches of rotor and stator lamination.

Our solutions

Explore Hexagon solutions for electric vehicle rotor and stator lamination inspectionMultisensor CMMs

The OPTIV range of multisensor coordinate measuring machines is ideal for the 2D and 3D measurement requirements of palletised sheet metal parts.

Optimised inspection software

PC-DMIS with the complementary Curve Analyzer software supports the complete analysis and processing of measured 2D profiles and is therefore ideal for sheet metal lamination inspection.