StereoScan neo

The new benchmark in optical 3D scanning

Would you like to know more?

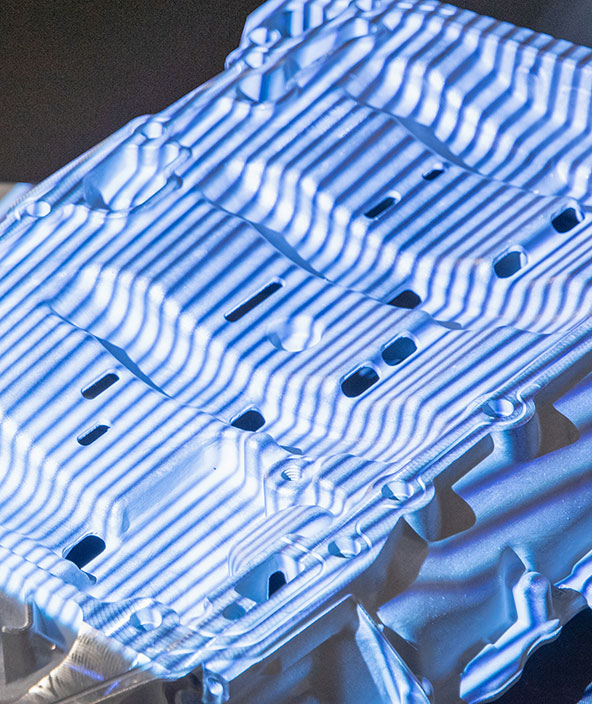

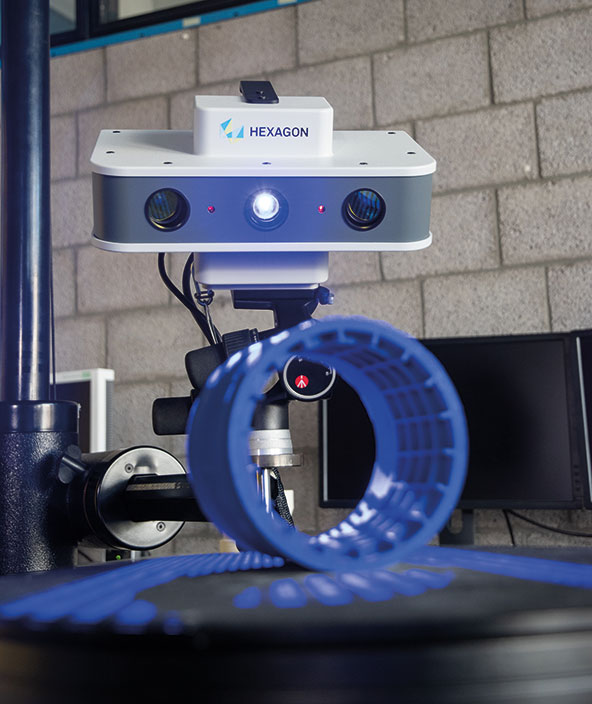

With the StereoScan neo, Hexagon introduces the innovative Smart Phase Projection (SPP) technology, which employs a new fringe projection pattern to yield the highest quality data on even the most difficult surfaces. The SPP technology represents a large step forward in optical 3D scanning, improving on classic fringe projection patterns to allow for better scanning of glossy and dark surfaces without pre-treatment.

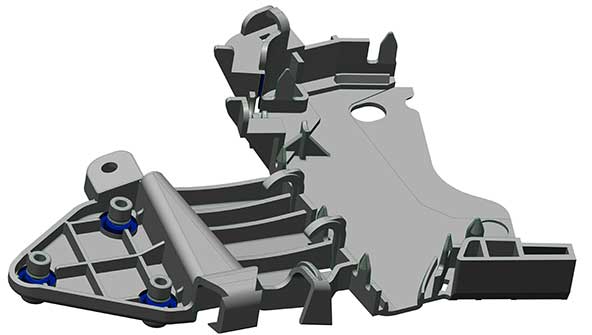

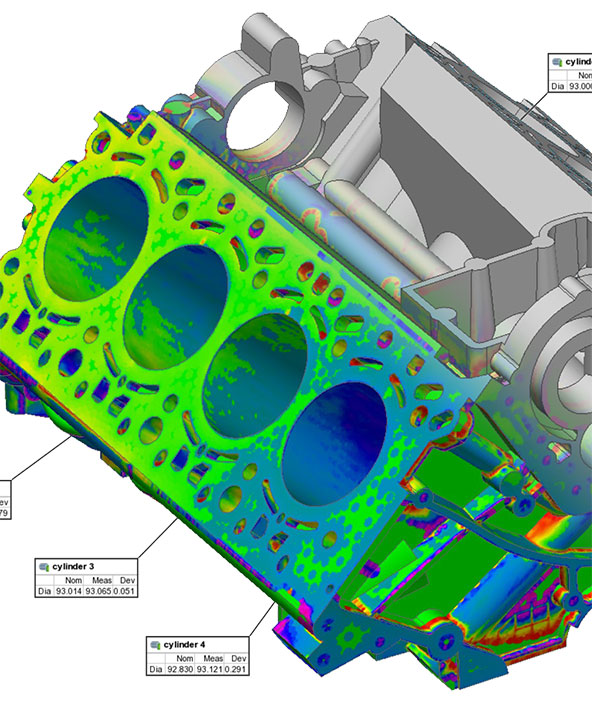

In the tooling and moulding industry or in the context of model making, deviations of the component surface can be measured and visualised quickly and precisely. Based on the projected deviation images, corrections on the object can be made promptly and on site. In a similar way, deviations identified during inspections can immediately visualised and corrected.

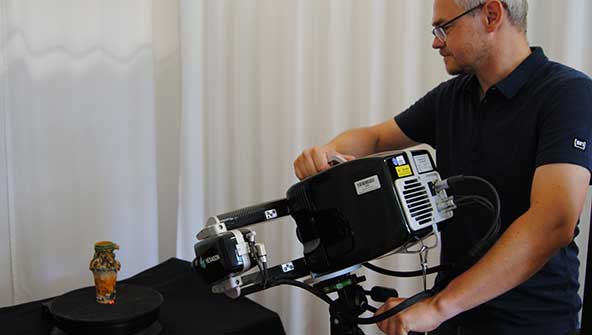

Equipped with a 16.8-megapixel digital camera, the StereoScan neo offers the best configuration to deliver the maximum degree of detail. Measurement fields ranging from 75 to 1000 millimetres can be captured by changing the camera lenses and the base length. This innovative sensor technology makes the StereoScan neo the most powerful and versatile white light scanners on the market.

Features and benefits

High speed

Short scanning times through fast digital projection.

Innovative scanning

Smart Phase Projection for scanning of glossy and dark surfaces without pre-treatment.

Intelligent scanning

Smart Data Capture technology allows for fast acquisition and variable resolution.

Result projection

Full colour back-projection of measurement results for easy post-measurement analysis.

Versatile measurement

Quick and easy exchange of measurement fields.

High resolution

Maximum degree of feature accuracy through high-resolution camera sensors and rigid design of the body.

Probing option

Compatible with the MI.Probe for measuring areas out of the line of sight of the scanner.

Robust construction

High-stability scanning based on a foundation of strong design and construction materials.

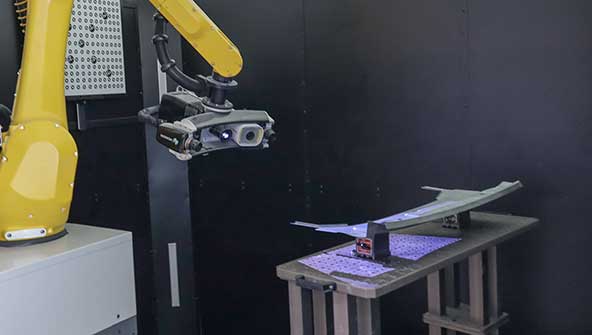

Automation ready

Ready for fully automated robotic inspection thanks to a rigid design and double carbon frame, as well as compatible with turntable and turn-tilt units for semi-automated measurement.

Combination with DPA series

Combinable with photogrammetry systems in the DPA Series for increased accuracy and capability for large-volume measurement.

Dedicated software plug-ins

Hexagon’s structured light scanner systems allow for deep integration with the leading third-party metrology software platforms through dedicated plug-ins created using the SLS SDK.

자동차 산업의 PartInspect L | 포르투갈에 위치한 MCG

자동차 부품 검사를 위한 턴키 셀

Scanning, photogrammetry and software plug-ins make measurement easier and more accurate

Simultaneous measurement and evaluation of multiple parts with PolyWorks

Straight-forward automation with structured light scanner technology

-

Customer stories

-

Downloads