Modelling and optimizing a blade antiroll system of Formula Student race car in MSC Adams

Introduction

For the 2019 season Unipr Racing Team has developed a completely new Formula Student race car, the PSR01. The Carbon fiber monocoque chassis and an electric propulsion are among the most important innovations in the new vehicle. The design process began in 2018 starting from scratch. For the Vehicle Dynamics and Suspension department, this also meant the creation of a vehicle assembly on the multibody simulation software Adams Car.

The double wishbone suspension system has been improved by the introduction of a blade antiroll system.

The actual effectiveness of the antiroll system has been simulated with Adams Car. The contribution of this simulation tool has been the key for the re-evaluation of dynamical parameters that had to be reconsidered after the manufacturing and assembly process due to the unexpected higher weight of the vehicle.

The antiroll system

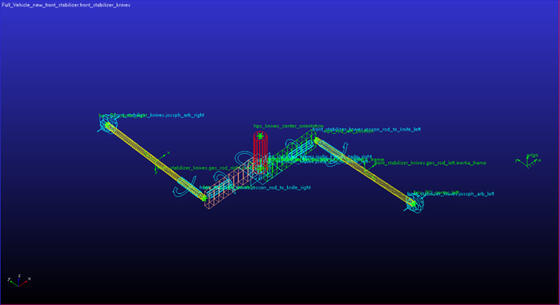

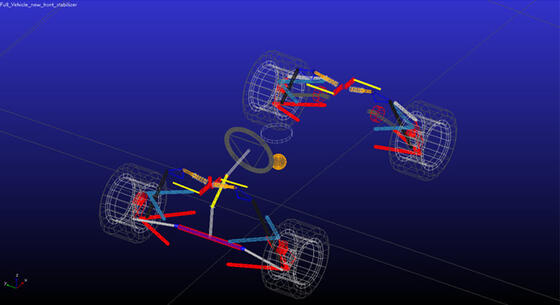

The blade antiroll system represents a simple but effective way to control the chassis body roll during corners. As shown in the picture above, two rods are connected through spherical joints to the rockers on one side and to the knives on the other. The knives are screwed to a central hub, which is free to rotate on the pivot on which it’s mounted with the use of bearings. As expected, the antiroll system has no function during squat/dive, since the rods act on the knives with equal forces that only cause the rotation of the hub. While cornering, the forces which the rods transmit to the blades are opposite in direction, and that cause them to flex. The effectiveness of the system depends on the rigidity of the blades. For a given material, the key point is to have the correct moment of inertia of the blade section in order to have the desired effectiveness.

Rotating the blades around their axis, many different adjustments can be chosen.

The analysis presented here has been conducted using 550 lb/inch springs at front and 700 lb/inch at rear. These has been chosen in order to meet the target values of natural frequency (3.2 Hz at front and 3.5 at rear). During the tests performed before the events, these values shown to be the optimum, especially in terms of longitudinal dynamics.

The simulation

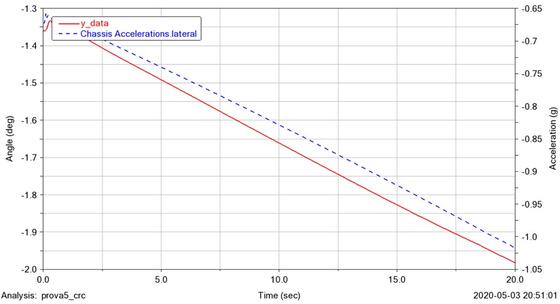

One of the key parameter set during the design of the car was the roll rate. Though a deep literature review and with the support of expert engineers, 1.5 degrees/g was chosen as default set up, and 1 degree/g as stiffer setup.

It was then necessary to understand the actual roll rate of the car, considering the unexpected added weight.

To do so, we performed structural analysis on the blades in order to estimate their rigidity in the different possible adjustments.

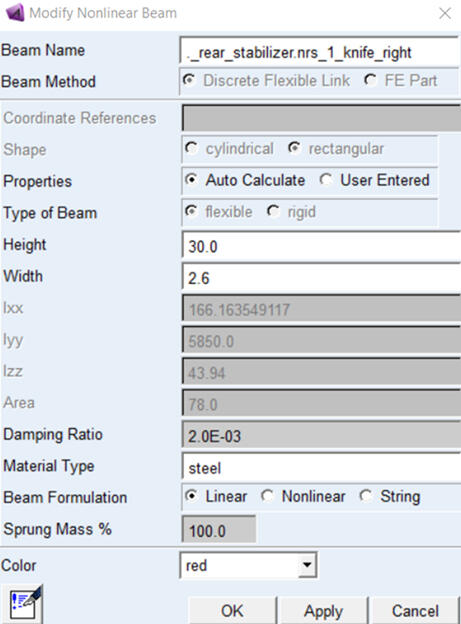

The system was simulated in ADAMS using the Nonlinear Beam function, which allowed to create a flexible component

In particular, the Discrete Flexible Link function was chosen. This means the flexible element is considered as a conjunction of different segments (in our case we have six of them) connected by a beam, which gives the actual flexibility to the part. In the Graphical Topology section, is it possible to inspect the morphology the Nonlinear beam. In the picture below the different segments connected to the rod in the terminal part of the blade are shown.

As shown in the picture of the antiroll subsystem, the convel joint has been used in the simulation in place of the spherical joint, used in the car. This because in Adams, two spherical joints wouldn’t be able to guarantee the equilibrium of the part during the simulation.

The actual knives do not have a regular shape (as shown In the picture below), such as the ones we modelled on Adams. Because of that an equivalent moment of inertia was defined starting from the FEM analysis result. The section of the nonlinear beam was than adjusted in order to obtain an equivalent component.

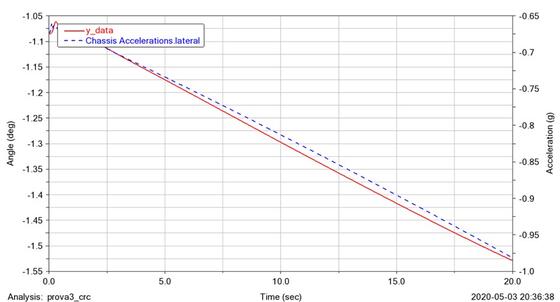

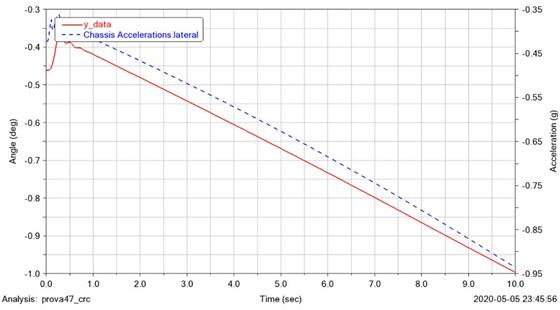

The Constant radius cornering test was analysed. As expected, in the default set up the car show a higher roll rate compared to the target value (about 2 degrees/g). Increasing progressively the nonlinear beam section, the desired result of 1.5 degrees/ g was obtained, as shown in the pictures below.

In the same way the stiffer set-up was also tested.

In conclusion, with ADAMS CAR we have been able to understand the real functionality of the antiroll system. Through the numerical data obtained in the simulation, the blades were redesigned and their functionality strongly improved. Keeping our assembly updated we are able to follow the development of our race car and have a constant feedback about the innovations we want to introduce.

The team

The UniPR Racing Team was founded in 2007 by a group of engineering students intending to enter the world of Formula SAE. It participated in the combustion category at all FSAE Italy stages from 2007 to 2017, at the Formula Student Imeche 2013 on the Silverstone track and in 2017 at the Formula Student Czech event on the Most track. The results obtained in the various editions together with the experience gained led the team in 2018 to the decision to start a new adventure in the Electric category. In the summer of 2018, the electric prototype project was presented at Varano obtaining the 2nd place in the Design competition.

In the last year the Team created the first electric single-seater, the PSR01, of the University of Parma thanks to the contribution of a Team of 47 people coming from 8 different courses of study.

We would like to say a big thank you to Daniele Catelani and Angelo Casolo, who supported us in our case study and made this possible.

Authors: Andrea Orezzi, Andrea Quarantelli