Validasi Desain Intergraph Smart P&ID

Intergraph Smart P&ID Design Validation Product Sheet

Choose Intergraph Smart P&ID Design Validation to check SmartPlant Isometrics, ISOGEN-generated isometrics, or PDMS 3D models against your Smart P&ID logical design.

Siap untuk memulai?

Bicaralah dengan pakar dan temukan apa yang dapat dilakukan Hexagon untuk organisasi Anda.

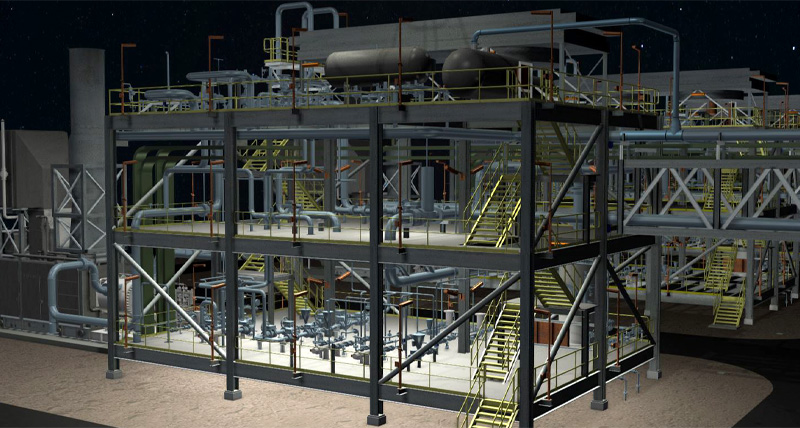

Intergraph Smart® P&ID Design Validation mempercepat alur kerja verifikasi sistem pipa yang iteratif, memeriksa konsistensi di antara desain pipa logis dan fisik. Design Validation memperlancar perbandingan di antara Intergraph Smart P&ID dan SmartPlant® Isometrics (PCF, POD); isometri/gambar yang dihasilkan oleh Isogen® (IDF, PCF); dan model PDMS.

Sebagai contoh, perbandingan cepat di antara isometri yang diperiksa di lapangan dapat memperlihatkan inkonsistensi topologi, di mana katup terletak di sisi cabang yang salah pada P&ID. Tugas-tugas smart engineering kemudian dapat digunakan untuk memperbarui P&ID agar mencerminkan situasi As-Built.

Sebagai contoh, perbandingan cepat di antara isometri yang diperiksa di lapangan dapat memperlihatkan inkonsistensi topologi, di mana katup terletak di sisi cabang yang salah pada P&ID. Tugas-tugas smart engineering kemudian dapat digunakan untuk memperbarui P&ID agar mencerminkan situasi As-Built.

Consistency

Facilitate As-Built between logical and physical designs. Improved consistency through rule-driven, intelligent graphical comparison.

Plant Safety

Make sure the designs are consistent to perform safety studies.

Reduce Risk

Plan maintenance and modification through synchronized engineering dataset.

Reduce Costs

Reduced labor by decreasing the number of iterative cycles.

Productivity

Make the right decision at the right time.

Design Consistency/Quality

Allows easy comparison of P&IDs (logical world) and isometrics, 3D models (physical world) at the data and topology levels.

Consistency

Facilitate As-Built between logical and physical designs. Improved consistency through rule-driven, intelligent graphical comparison.

Plant Safety

Make sure the designs are consistent to perform safety studies.

Reduce Risk

Plan maintenance and modification through synchronized engineering dataset.

Reduce Costs

Reduced labor by decreasing the number of iterative cycles.

Productivity

Make the right decision at the right time.

Design Consistency/Quality

Allows easy comparison of P&IDs (logical world) and isometrics, 3D models (physical world) at the data and topology levels.

Consistency

Facilitate As-Built between logical and physical designs. Improved consistency through rule-driven, intelligent graphical comparison.

Plant Safety

Make sure the designs are consistent to perform safety studies.

Reduce Risk

Plan maintenance and modification through synchronized engineering dataset.

Reduce Risk

Plan maintenance and modification through synchronized engineering dataset.

Reduce Costs

Reduced labor by decreasing the number of iterative cycles.

Productivity

Make the right decision at the right time.

Design Consistency/Quality

Allows easy comparison of P&IDs (logical world) and isometrics, 3D models (physical world) at the data and topology levels.

Consistency

Facilitate As-Built between logical and physical designs. Improved consistency through rule-driven, intelligent graphical comparison.

Plant Safety

Make sure the designs are consistent to perform safety studies.

Reduce Risk

Plan maintenance and modification through synchronized engineering dataset.

Reduce Costs

Reduced labor by decreasing the number of iterative cycles.

Productivity

Make the right decision at the right time.

Design Consistency/Quality

Allows easy comparison of P&IDs (logical world) and isometrics, 3D models (physical world) at the data and topology levels.

Consistency

Facilitate As-Built between logical and physical designs. Improved consistency through rule-driven, intelligent graphical comparison.

Plant Safety

Make sure the designs are consistent to perform safety studies.

Reduce Risk

Plan maintenance and modification through synchronized engineering dataset.

Reduce Work

Reduce checking cost during project executions. The P&ID can be checked against the 3D design and the isometrics to ensure design consistency and reduce change order when the isometrics are issued to the fabricator.

Highlight Inconsistencies

Both data as well as graphical identification of the inconsistency. The tool will show side-by-side data that is inconsistent.

Manage Inconsistencies

Within the tool there is a note pad capabilities to document the actions and by whom to resolve the inconsistencies.

Side-by-side Comparison

Compare logical and physical designs. Side-by-side comparison for example the P&ID and the isometric showing the difference in data as well as in topology.

Automatic Reporting

Automatic reporting on differences in 2D and 3D. The tool will automatically create a word document with descriptions of the difference and screen shots of the P&ID and the 3D isometric with the highlited inconsistencies.

Reduce Cost on Plant Maintenance

The comparison will make sure that in case of maintenance and or turn around projects there will be no suprises when the planning is done on P&ID and find different configurations in the actual plant.

Reduce Work

Reduce checking cost during project executions. The P&ID can be checked against the 3D design and the isometrics to ensure design consistency and reduce change order when the isometrics are issued to the fabricator.

Highlight Inconsistencies

Both data as well as graphical identification of the inconsistency. The tool will show side-by-side data that is inconsistent.

Manage Inconsistencies

Within the tool there is a note pad capabilities to document the actions and by whom to resolve the inconsistencies.

Side-by-side Comparison

Compare logical and physical designs. Side-by-side comparison for example the P&ID and the isometric showing the difference in data as well as in topology.

Automatic Reporting

Automatic reporting on differences in 2D and 3D. The tool will automatically create a word document with descriptions of the difference and screen shots of the P&ID and the 3D isometric with the highlited inconsistencies.

Reduce Cost on Plant Maintenance

The comparison will make sure that in case of maintenance and or turn around projects there will be no suprises when the planning is done on P&ID and find different configurations in the actual plant.

Reduce Work

Reduce checking cost during project executions. The P&ID can be checked against the 3D design and the isometrics to ensure design consistency and reduce change order when the isometrics are issued to the fabricator.

Highlight Inconsistencies

Both data as well as graphical identification of the inconsistency. The tool will show side-by-side data that is inconsistent.

Manage Inconsistencies

Within the tool there is a note pad capabilities to document the actions and by whom to resolve the inconsistencies.

Manage Inconsistencies

Within the tool there is a note pad capabilities to document the actions and by whom to resolve the inconsistencies.

Side-by-side Comparison

Compare logical and physical designs. Side-by-side comparison for example the P&ID and the isometric showing the difference in data as well as in topology.

Automatic Reporting

Automatic reporting on differences in 2D and 3D. The tool will automatically create a word document with descriptions of the difference and screen shots of the P&ID and the 3D isometric with the highlited inconsistencies.

Reduce Cost on Plant Maintenance

The comparison will make sure that in case of maintenance and or turn around projects there will be no suprises when the planning is done on P&ID and find different configurations in the actual plant.

Reduce Work

Reduce checking cost during project executions. The P&ID can be checked against the 3D design and the isometrics to ensure design consistency and reduce change order when the isometrics are issued to the fabricator.

Highlight Inconsistencies

Both data as well as graphical identification of the inconsistency. The tool will show side-by-side data that is inconsistent.

Manage Inconsistencies

Within the tool there is a note pad capabilities to document the actions and by whom to resolve the inconsistencies.

Side-by-side Comparison

Compare logical and physical designs. Side-by-side comparison for example the P&ID and the isometric showing the difference in data as well as in topology.

Automatic Reporting

Automatic reporting on differences in 2D and 3D. The tool will automatically create a word document with descriptions of the difference and screen shots of the P&ID and the 3D isometric with the highlited inconsistencies.

Reduce Cost on Plant Maintenance

The comparison will make sure that in case of maintenance and or turn around projects there will be no suprises when the planning is done on P&ID and find different configurations in the actual plant.

Reduce Work

Reduce checking cost during project executions. The P&ID can be checked against the 3D design and the isometrics to ensure design consistency and reduce change order when the isometrics are issued to the fabricator.

Highlight Inconsistencies

Both data as well as graphical identification of the inconsistency. The tool will show side-by-side data that is inconsistent.

Manage Inconsistencies

Within the tool there is a note pad capabilities to document the actions and by whom to resolve the inconsistencies.

Kursus Pelatihan Virtual P&ID Cerdas

Kursus Pelatihan Virtual menawarkan pelatihan mendalam dengan kenyamanan tanpa harus meninggalkan kantor Anda.

Intergraph Smart P&ID

Intergraph Smart P&ID membantu Anda mengembangkan dan mengelola diagram perpipaan dan instrumentasi dengan fokus pada aset pabrik.

Pusat Sumber Daya

Kunjungi Pusat Sumber Daya kami dan jelajahi brosur solusi, studi kasus pelanggan, lembar produk, video, laporan resmi, dan lainnya.

Jangan Lewatkan!

Berlanggananlah kabar terbaru Hexagon untuk mendapatkan berita dan informasi produk terbaru langsung ke kotak masuk Anda.