Hexagon의 제조 인텔리전스 사업부

Hexagon의 제조 인텔리전스 사업부는 제조업체가 제한 없이 혁신하고 창작할 수 있도록 지원합니다. 당사의 솔루션은 제품 수명 주기 전반에 걸쳐 최적화를 지원하며, 크리에이터가 사람과 지구를 위한 새롭고 혁신적인 방법으로 더 나은 제품을 생산할 수 있도록 합니다.

Explore Manufacturing Intelligence

Metrology

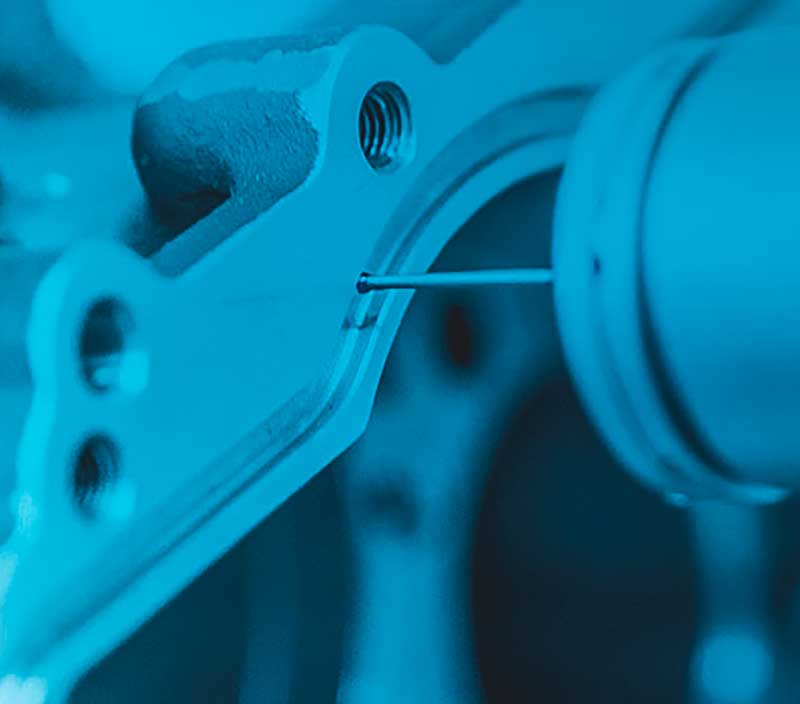

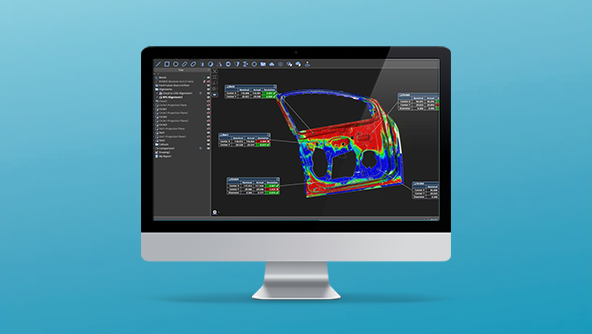

Get it right first time with the insights from last time. Hexagon’s metrology solutions help you to close the gap between design intent and real-world operation with actionable, real-time insight that revolutionises upstream and downstream decision-making.

The role of metrology within the manufacturing process has long been associated with quality assurance – a post-production inspection of the dimensional measurements of a part against specifications.

Results indicated that the part was either good to go, or not to standard, at best requiring reworking or at worst scrapping. Metrology was the necessary evil – quality almost becoming a barrier to productivity.

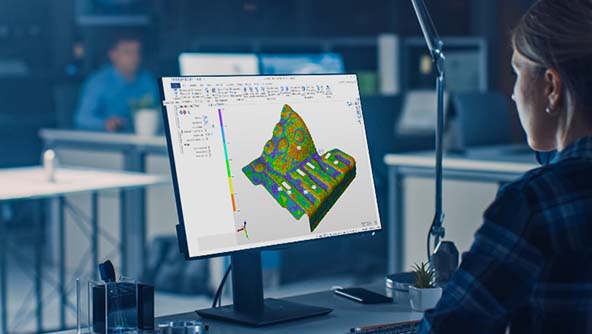

Production

Push production to the limits. Make what they said was unmakeable. Bring innovations to life in incredible new ways. See design intent through into market ready products. Our solutions empower makers to turn imagination into reality. Spanning machining, forming, casting, moulding, joining, 3D printing, or a combination of multiple processes – the production floor is where components take shape.

Production is where product quality is set in stone, metal, wood or composite and the pursuit of manufacturing ‘right first time’ is the highest priority. It’s the manufacturing process phase where productivity really matters – efficiency and throughput are essential to remain competitive – costs must be controlled and downtime avoided. This is where you need design intent to be maintained through the production cycle.

Design and Engineering

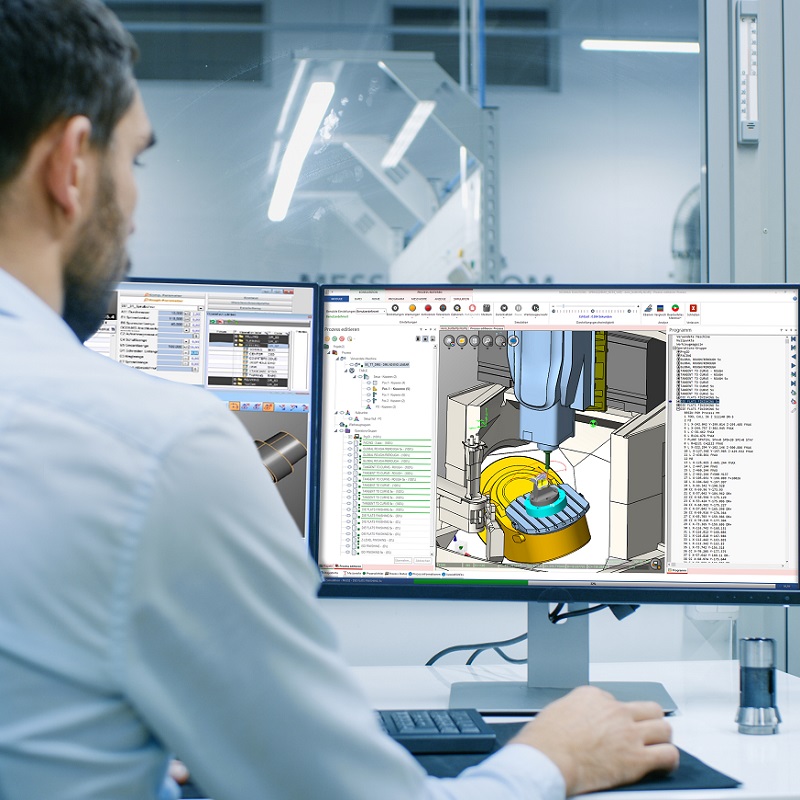

Hexagon software sits at the leading edge of production innovation making it possible to produce things that were previously unthinkable by entirely rethinking both products and production through design, materials, manufacturing and process innovation.

We passionately believe that if it can be imagined, it can be made, so we develop our solutions to remove all barriers to possibility.

By harnessing the power of data and technology our tools unlock new avenues for exploration and provide extra lift to the creative process.

Hexagon의 제조 인텔리전스 사업부는 고객이 제품을 발명, 설계, 제조, 테스트 또는 서비스할 때 제한 없이 제품을 제작할 수 있도록 지원합니다.

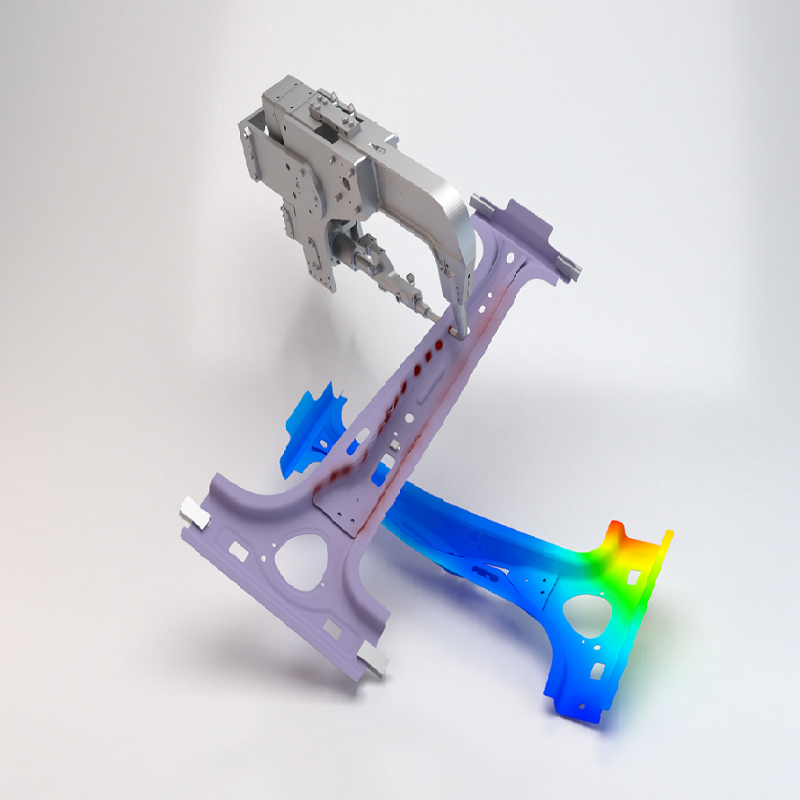

당사의 기술은 가능성에 대한 장벽을 제거하고 제조업체가 제조 혁신을 통해 우리가 알고 있는 세상을 재정의할 수 있도록 지원합니다. 개념에서 수명 종료에 이르기까지, 당사의 솔루션은 전체 가치 사슬에 걸쳐 최적화를 제공하여 설계, 시뮬레이션, 테스트, 자재 선택, 제조 설계 계획, 생산, 검사 및 실제 성능을 변화시킵니다.

Hexagon의 스마트 제조 포트폴리오는 전체 제품 및 생산 라이프사이클을 지원하여 잠재력을 높이고 문제가 발생하기 전에 해결하며 상당한 이익을 제공합니다. 하드웨어와 소프트웨어를 통해 물리적 세계와 디지털 세계를 한데 모으고, 제조업체는 아이디어화, 탐색, 처음부터 올바른 설치, 지속 가능한 생산 규모를 조정할 수 있습니다.

비용, 품질, 혁신 및 지속 가능성에 대한 선순환 고리를 만들어 새롭고 혁신적인 방법으로 더 나은 제품을 만들고 싶다면 멀리서 찾을 필요가 없습니다.

제조사가 우위를 확보하고, 산업을 형성하며, 지속적인 변화를 창출할 수 있도록 지원합니다.

Hexagon's Manufacturing Intelligence division helps customers put data to work to improve productivity and efficiency while embedding quality throughout the product lifecycle.

Our manufacturing intelligence technology enables manufacturers to access, analyse and actively use data from all the key stages of the manufacturing process. Through an unparalleled portfolio of digital manufacturing technologies spanning CAE solutions for design and engineering, CAD CAM and complementary software for production applications, metrology hardware and software solutions, as well as data management and analytics tools, we empower technology users throughout the process with deep and actionable insight into product quality, ensuring that quality drives productivity.

Together, our manufacturing intelligence software solutions create a digital thread throughout the manufacturing process, enabling the entire organisation to take a holistic approach and work together with speed and confidence to achieve the desired outcomes.

Our hardware solutions use metrology to bring real-world physical attributes to the digital thread to improve the accuracy of operations. The digital thread ties together a connected ecosystem for manufacturing and, with the addition of domain expertise and intelligence, enables continuous learning and improvement.

-

FeaturedProduct

FeaturedProductThe SmartScan VR800 offers a patented dual stereo camera plus mechanical optical zoom projection unit setup.

-

×Partial autonomyAutomated execution and analysis of inspection part program in combination with turntable and/or turn-tilt-units.

-

-

FeaturedProduct

FeaturedProduct어디서나 간편하게 측정할 수 있는 무선 휴대용 3D 스캐너

-

×Full autonomy완전한 자율 검사 시스템 내 통합이 가능하도록 자동화 지원.

-

-

FeaturedSolution

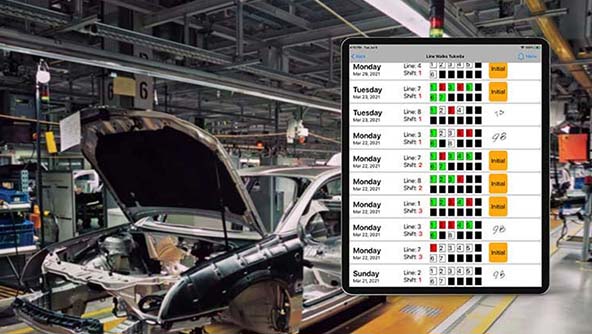

FeaturedSolutionSmart Audits

×Line WalksOften called operator rounds or line walks, these digital checklists ensure machines are calibrated and running optimally.

-

FeaturedProduct

FeaturedProductQ-DAS qs-STAT is a software package designed to evaluate and assess production-relevant quality information statistically.

-

×Human-Assisted autonomyProcess qualification analysis

-

-

FeaturedProduct

FeaturedProduct어디서나 무선 및 타겟 프리 측정이 가능한 사진 측량 기능이 탑재된 핸드헬드 3D 스캐너.

-

×Full autonomy완전한 자율 검사 시스템 내 통합이 가능하도록 자동화 지원

-

-

FeaturedProduct

FeaturedProductReal-Time Monitoring

×AR MonitoringAugmented reality solution to view machine data in real time.

All products

Partnerships

Resources

- 18 7월 2024

- 27 6월 2024

- 20 6월 2024

- 10 6월 2024

- 05 6월 2024