Electronics industry

Providing simulation, production and inspection solutions to enable improved design, quality, cost-effectiveness and productivity in electronics manufacturing.

Digitalising the global electronics industry

Delivering end-to-end solutions and process autonomy in the electronics industry.

Ready to learn how Hexagon's capabilities can empower your business?

Hexagon’s digital transformation solutions and software empower the electronics industry to overcome many of the challenges it faces today. With a complex global supply chain and the need for shorter product cycles to attend to changing consumer preferences, there is constant pressure to implement consistency and maintain high quality.

Explore capabilities

-

Manufacturing

-

Cities and nations

-

Industrial facilities

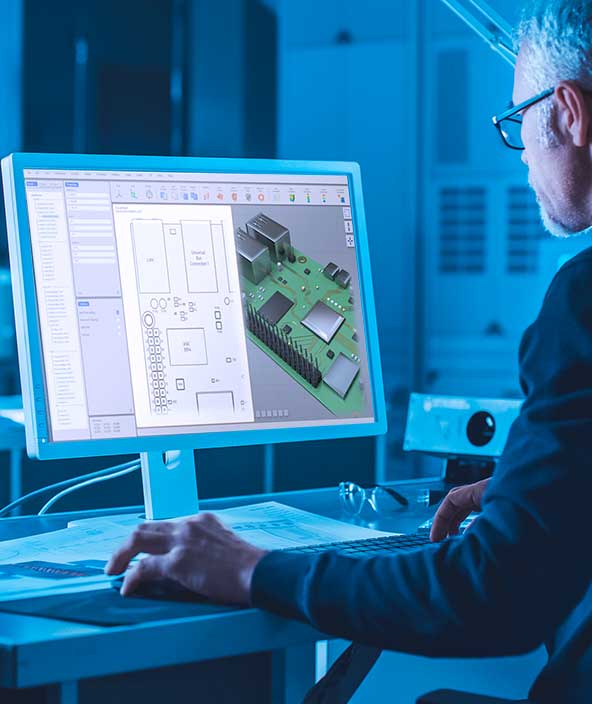

Design and engineering phase

With Hexagon’s innovations in manufacturing technology, users can digitally simulate and optimise product design and engineering to ensure component manufacturability, production productivity and output quality.

Production phase

Maintain a digital thread through production, optimise machine tools, measure environmental variances and prevent downtime with predictive data analyses.

Inspection phase

Automate and digitalise quality measurement with our world-leading metrology hardware and software, creating a bridge between the real and digital worlds.

Digital transformation

Deploy Hexagon’s sensor software systems to transform siloed and disconnected processes into an integrated, data-driven manufacturing ecosystem that captures and creates value across the product lifecycle, enabling new business models and automating workflows to become increasingly autonomous, efficient and sustainable.

Industrial and commercial resiliency

Forge safer industrial and commercial facilities with scalable surveillance, security and incident management capabilities.

Operate and maintain phase

Leverage data from the planning, design and build phases to create an operational twin that connects people, processes and events throughout the entire industrial facility lifecycle.