Anything but a bottleneck: coordinate metrology in toolmaking

Corvaglia - Switzerland

Contact us

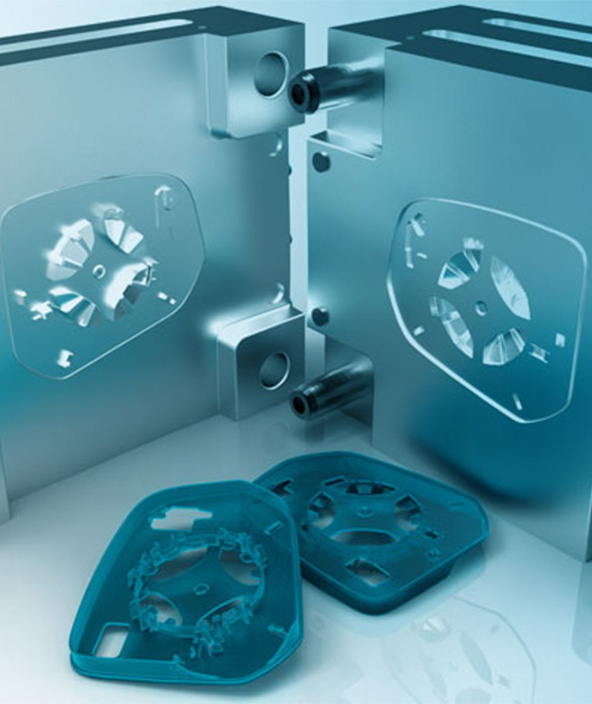

The Corvaglia Group based in Eschlikon in eastern Switzerland is a top performer in every sense. The company is a specialist manufacturer of inexpensive caps and closures for PET bottles. Along with plastic injection moulding, toolmaking has a major role to play at Corvaglia. To avoid toolmaking becoming a bottleneck, Corvaglia calls upon technology from Hexagon Manufacturing Intelligence: the team uses a DEA GLOBAL coordinate measuring machine with PC-DMIS software for presetting. The advantage: the electrical discharge machining (EDM) equipment can run non-stop as the operatives set-up the parts away from the machines.

.jpg?hash=E3E026BE034A0E882D6CCD624379FA75ABB138AC&h=345&w=329) A piece of Corvaglia know-how is present in one in every five PET bottles worldwide: they have a closure that was manufactured with a Corvaglia tool. Romeo Corvaglia founded the company in 1991. Then the company only involved itself with the design of closures and injection moulds. Taking over the mould manufacturer Kellenberger AG 1997 was the final step to becoming a full-service provider of PET closures.

A piece of Corvaglia know-how is present in one in every five PET bottles worldwide: they have a closure that was manufactured with a Corvaglia tool. Romeo Corvaglia founded the company in 1991. Then the company only involved itself with the design of closures and injection moulds. Taking over the mould manufacturer Kellenberger AG 1997 was the final step to becoming a full-service provider of PET closures.

Professional presetting: the coordinate measuring machine

The daily work of the toolmaker at Corvaglia revolves around cavities, cores and electrodes. Before the cavity goes into the spark erosion machine for cutting, the team sets up the parts using a coordinate measuring machine (CMM) from the DEA GLOBAL Performance series. The measuring machine offers a measuring range of 500 x 700 x 500 mm and a volumetric length measurement deviation of 1.7 + L/333 microns. In the matter of accuracy the DEA GLOBAL is a match for the spark erosion machines. The CLIMA temperature compensation system allows the CMM to measure to consistent accuracy in a temperature range of 16 to 26 °C. And to complement the hardware, there is the appropriate software: PC-DMIS EDM Preset & Measure – a software add-on that was specially developed for presetting.

The toolsetters place the parts into position for presetting using a mounting system. The mounting system – whether it has cavities, cores or electrodes – is fitted with a chip to enable identification. The chip is read and the zero point of the pallet determined with the measuring machine. Then the user enters the pallet grid into the PC-DMIS EDM Preset & Measure software. In manual mode by single point acquisition, the toolmaker determines the X-Y-Z coordinates of the first cavity using the measuring system.

The coordinate measuring machine calculates the offset data for the rest of the cavities automatically. The calculated data are stored. Every cutting machine has access to the measured data and accurate spark-erosion is ensured.

.png?hash=8C3D173D08E705EACCEBC93574D3264D08FD14F8&h=214&w=400)

No breaks for spark erosion machines

“Thanks to the DEA GLOBAL we can run our spark erosion machines non-stop,” says Lorenz Jordi, Department Manager at Corvaglia Mould AG. “The setting up is now done at the measuring station. In earlier days we set up directly in the spark erosion machines. While this was happening, the spindle had to be stationary and we could not erode. Nowadays all we have to do is load the spark erosion machines with the pallets. With our new automatic spark erosion machines in combination with the measuring machine, we have recorded an increase in throughput of 70% of which 15% can be attributed to the measuring machine. “

Automatic beats manual

Corvaglia is profiting not only from a higher throughput but also from a lower error rate for presetting. “In earlier times we bolted the cavities on to the pallets, the zero point was determined using a manual measuring machine, the coordinates of each cavity were measured and the position of the cavities read into the cutting machine,” says Elmar Deuer, a toolmaker at Corvaglia. “Now all this takes place automatically with the DEA GLOBAL. The offset data are passed in a secure manner to the spark erosion machines and the machines ‘know’ exactly where the parts are. That is sensational.”

Not to be underestimated among the advantages of the DEA GLOBAL with PC-DMIS EDM Preset & Measure is the wide-ranging experience Hexagon has in toolmaking measurement applications.

In future 3D with CAD

Presetting will not remain the limit for DEA GLOBAL at Corvaglia. The team already has its eyes set on checking complete tools from mould production with 3D-capable measuring machines. Peter Kistler explains: “At the moment we use DEA GLOBAL solely for positional identification for the mould components. In future it is planned to measure the whole mould tool, which currently our colleagues carry out in a separate measuring room on another measuring machine. We would now like to extend the DEA GLOBAL with a CAD module and exploit the full potential of this coordinate measuring machine.”

.jpg?hash=E3E026BE034A0E882D6CCD624379FA75ABB138AC&h=345&w=329) A piece of Corvaglia know-how is present in one in every five PET bottles worldwide: they have a closure that was manufactured with a Corvaglia tool. Romeo Corvaglia founded the company in 1991. Then the company only involved itself with the design of closures and injection moulds. Taking over the mould manufacturer Kellenberger AG 1997 was the final step to becoming a full-service provider of PET closures.

A piece of Corvaglia know-how is present in one in every five PET bottles worldwide: they have a closure that was manufactured with a Corvaglia tool. Romeo Corvaglia founded the company in 1991. Then the company only involved itself with the design of closures and injection moulds. Taking over the mould manufacturer Kellenberger AG 1997 was the final step to becoming a full-service provider of PET closures.The portfolio: a nice piece of work

The company has successively extended its knowledge in this field. Today Corvaglia offers a complete portfolio of products and services centred on plastic closures: starting with the design, development and toolmaking through injection moulding all the way to providing the associated services. “Our strategy is to offer the customer everything in the field of PET closures from the bottom up,” says Peter Kistler, Production Manager at Corvaglia Mould AG. “We even influence the design of the bottle necks with our development work. We are continuously striving to make the production of closures even more cost-effective, e.g. by designing the closures in such a way that they require less plastic for production.”Tools in continuous use

The demands made upon the tools are brought home by the numbers involved: Corvaglia tools used in Swiss industry have a daily output of about 3 million pieces and must perform their task for between three to five years. 20,000 to 30,000 bottles per hour flow through a typical bottling plant. By comparison, the cycle time in the vehicle manufacturing industry is about 30 seconds. PET closures are mass produced on a huge scale, precisely manufactured mould tools are therefore paramount. Corvaglia works with a modular system for its mould tools. The mould tool assemblies are always similar. What changes from job to job are the mould inserts, which are manufactured with the help of three diesinking machines.

Professional presetting: the coordinate measuring machine

The daily work of the toolmaker at Corvaglia revolves around cavities, cores and electrodes. Before the cavity goes into the spark erosion machine for cutting, the team sets up the parts using a coordinate measuring machine (CMM) from the DEA GLOBAL Performance series. The measuring machine offers a measuring range of 500 x 700 x 500 mm and a volumetric length measurement deviation of 1.7 + L/333 microns. In the matter of accuracy the DEA GLOBAL is a match for the spark erosion machines. The CLIMA temperature compensation system allows the CMM to measure to consistent accuracy in a temperature range of 16 to 26 °C. And to complement the hardware, there is the appropriate software: PC-DMIS EDM Preset & Measure – a software add-on that was specially developed for presetting.The toolsetters place the parts into position for presetting using a mounting system. The mounting system – whether it has cavities, cores or electrodes – is fitted with a chip to enable identification. The chip is read and the zero point of the pallet determined with the measuring machine. Then the user enters the pallet grid into the PC-DMIS EDM Preset & Measure software. In manual mode by single point acquisition, the toolmaker determines the X-Y-Z coordinates of the first cavity using the measuring system.

The coordinate measuring machine calculates the offset data for the rest of the cavities automatically. The calculated data are stored. Every cutting machine has access to the measured data and accurate spark-erosion is ensured.

.png?hash=8C3D173D08E705EACCEBC93574D3264D08FD14F8&h=214&w=400)

No breaks for spark erosion machines

“Thanks to the DEA GLOBAL we can run our spark erosion machines non-stop,” says Lorenz Jordi, Department Manager at Corvaglia Mould AG. “The setting up is now done at the measuring station. In earlier days we set up directly in the spark erosion machines. While this was happening, the spindle had to be stationary and we could not erode. Nowadays all we have to do is load the spark erosion machines with the pallets. With our new automatic spark erosion machines in combination with the measuring machine, we have recorded an increase in throughput of 70% of which 15% can be attributed to the measuring machine. “

Automatic beats manual

Corvaglia is profiting not only from a higher throughput but also from a lower error rate for presetting. “In earlier times we bolted the cavities on to the pallets, the zero point was determined using a manual measuring machine, the coordinates of each cavity were measured and the position of the cavities read into the cutting machine,” says Elmar Deuer, a toolmaker at Corvaglia. “Now all this takes place automatically with the DEA GLOBAL. The offset data are passed in a secure manner to the spark erosion machines and the machines ‘know’ exactly where the parts are. That is sensational.”Crystal-clear operator guidance

Elmar Deuer is also impressed by PC-DMIS EDM Preset & Measure. The graphical user interface is easy to understand, according to Deuer. The Hexagon technicians trained him on the program over two days. He was then able very quickly to pass on his knowledge to his colleagues.Not to be underestimated among the advantages of the DEA GLOBAL with PC-DMIS EDM Preset & Measure is the wide-ranging experience Hexagon has in toolmaking measurement applications.