Volume optimized cutting and polishing of uncut "rough" gemstones

Contact us

Cutting and polishing gemstones – a craft involving profound knowledge and a long standing tradition of turning precious raw material into unique pieces of jewelry. Using a modern three-dimensional scanning technology now allows for a much improved utilization of the raw gemstone to become the perfectly cut and polished precious stone.

3D digitization of valuable objects

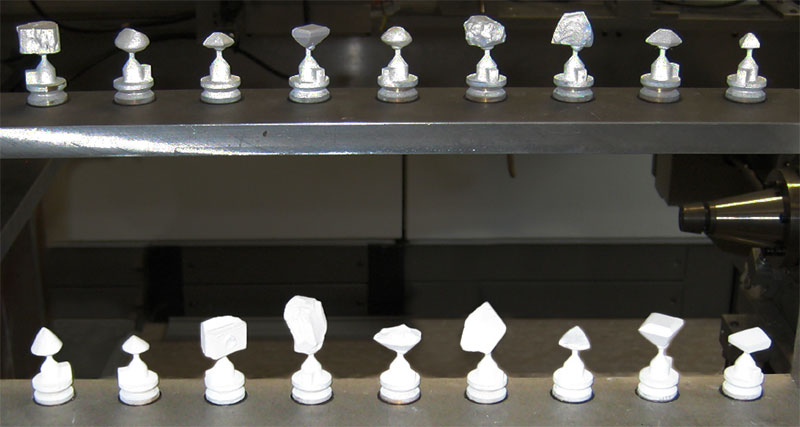

After completing the manual cutting procedure, surprisingly little of the valuable source material remains for further processing: Approximately two thirds of the uncut gemstone is lost through the cutting process and only one third is processed into a jewelry stone. The 3D measurement of the uncut gemstone with the AICON SmartScan not only serves the purpose to minimize this cutting wastage, and in doing so to achieve a higher price; the resulting 3D data also serves as a basis for the subsequent fully automated polishing process.

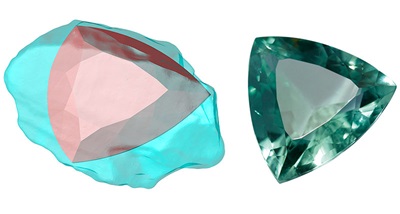

In order to utilize the uncut gemstone to its optimum potential, the fundamental objective of the gemstone cutter is to identify the best possible cut pattern for each and every source stone, with colored gemstones being characterized by countless combinations of cutting and polishing shapes, proportions and pane patterns. To date, this process used to be entirely carried out by hand, and the choice of the individual cut was based exclusively on the knowledge and experience of the respective craftsman.

The uncut, small-sized gemstone features a very irregular geometry which in the context of its data acquisition pose of particular difficulty for traditional digitization devices. Thanks to an advanced and innovative technology developed by AICON, it is now possible to conduct the cutting and polishing process entirely automated.

The uncut, small-sized gemstone features a very irregular geometry which in the context of its data acquisition pose of particular difficulty for traditional digitization devices. Thanks to an advanced and innovative technology developed by AICON, it is now possible to conduct the cutting and polishing process entirely automated.

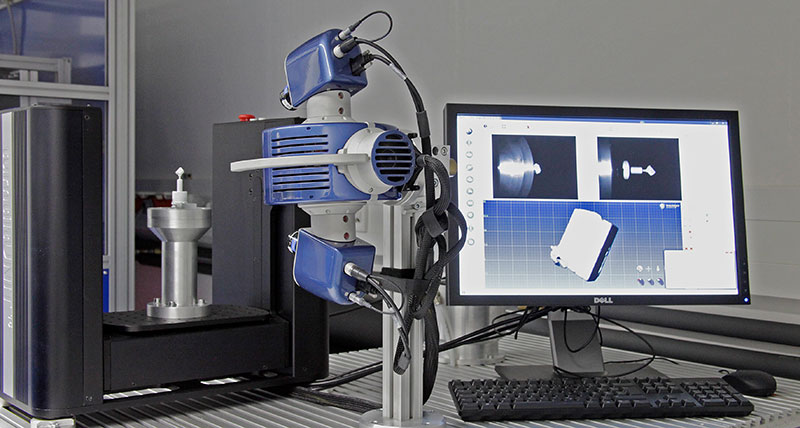

By using a turn/tilt unit fed with the uncut gemstones by a robot, the measuring procedure can be carried out completely automated. As the case may be depending on its individual transparency, the uncut gemstone may have to be coated with a removable matting surface. Given its extremely fast image generating time of less than 1 second, the AICON SmartScan precisely and efficiently captures the complete complex geometry of the stone.

A high-precision calibration, which can be carried out by the user within a matter of minutes, ensures highest level of accuracy at all times. Depending on the size of each stone, varying fields of view measuring from 25 mm to 50 mm in image diagonal are being used. After the scanning process, the object geometry is calculated and visualized, readily available for further processing in less than 10 minutes.

Automated cutting for optimum jewelry stones

The 3D data of the uncut gemstone captured by the digitization system is exported to a software especially developed by the Fraunhofer Institute for Technological and Industrial Mathematics ITWM (Kaiserslautern, Germany). It calculates the optimum embeddings, proportions and pane pattern for a variety of shapes and provides the user with a selection of different proposals. In the following step, the uncut gemstones are brought into the perfect shape and polished in a 17-axis gemstone cutting machine.

Time savings and increase in value

As result of a sophisticated, highly efficient and fully automated operating sequence, the AICON SmartScan measures the volumes of the individual uncut gemstones and delivers precise 3D data for immediate further processing. Any optimization measures carried out on the basis of this 3D data not only results in a significant time saving in connection with the measurement but also in a considerably reduced wastage of raw material in the subsequent cutting and polishing process. The final gemstones maintain a higher weight and therefore also a higher value when compared to the gemstones resulting from the manual cutting process.

We give thanks to Paul Wild GmbH and Mr. Andreas Dinges (ITWM) for their support in creating this report.