Adams Real Time

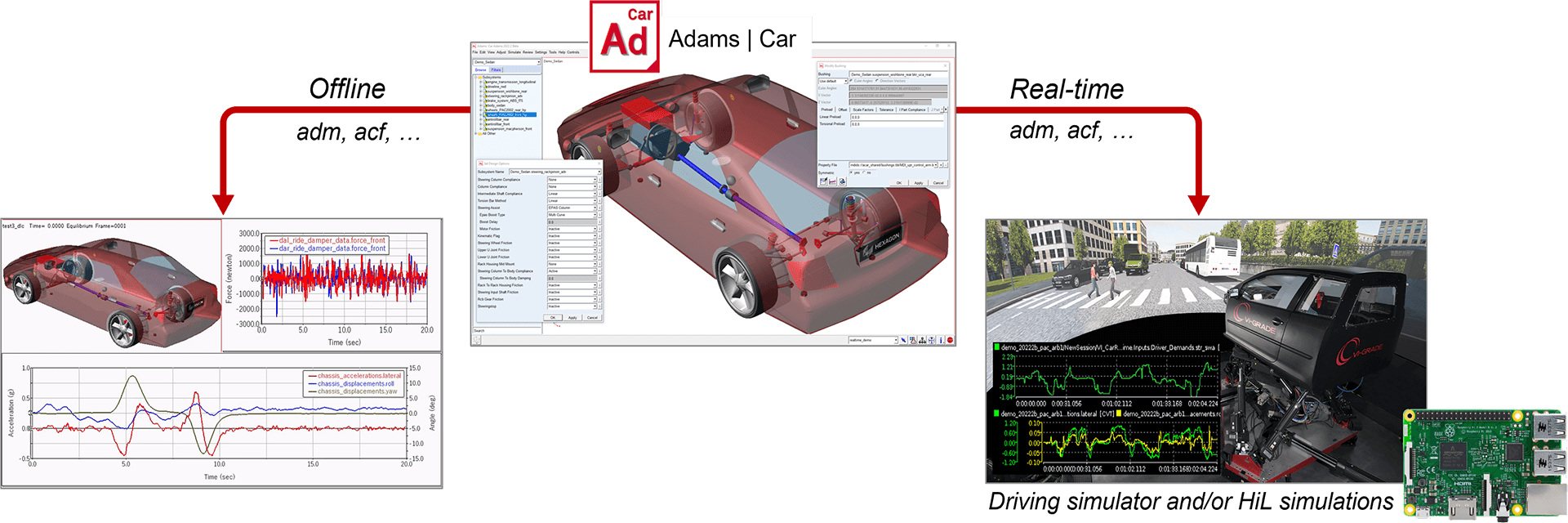

Perform software-in-loop (SIL), hardware-in-loop (HIL) and advanced driver assistance systems (ADAS) co-simulations with Adams for reduced prototyping.

Validate products in real time without prototypes

Adams RT integrates high-fidelity multi-body dynamics (MBD) models with hardware and control software (XIL) flawlessly.

Ready to learn more?

Minimal effort to model, simulate and refine systems

Adams RT utilizes pre-existing Adams MBD models directly in real time set up (XIL) and reduces model development time from several weeks to a few hours. Its true parametric modelling approach enables engineers to tune the mechanical system models on the spot (try out and test multiple design configurations in minutes).

Make more informed decisions without physical prototypes

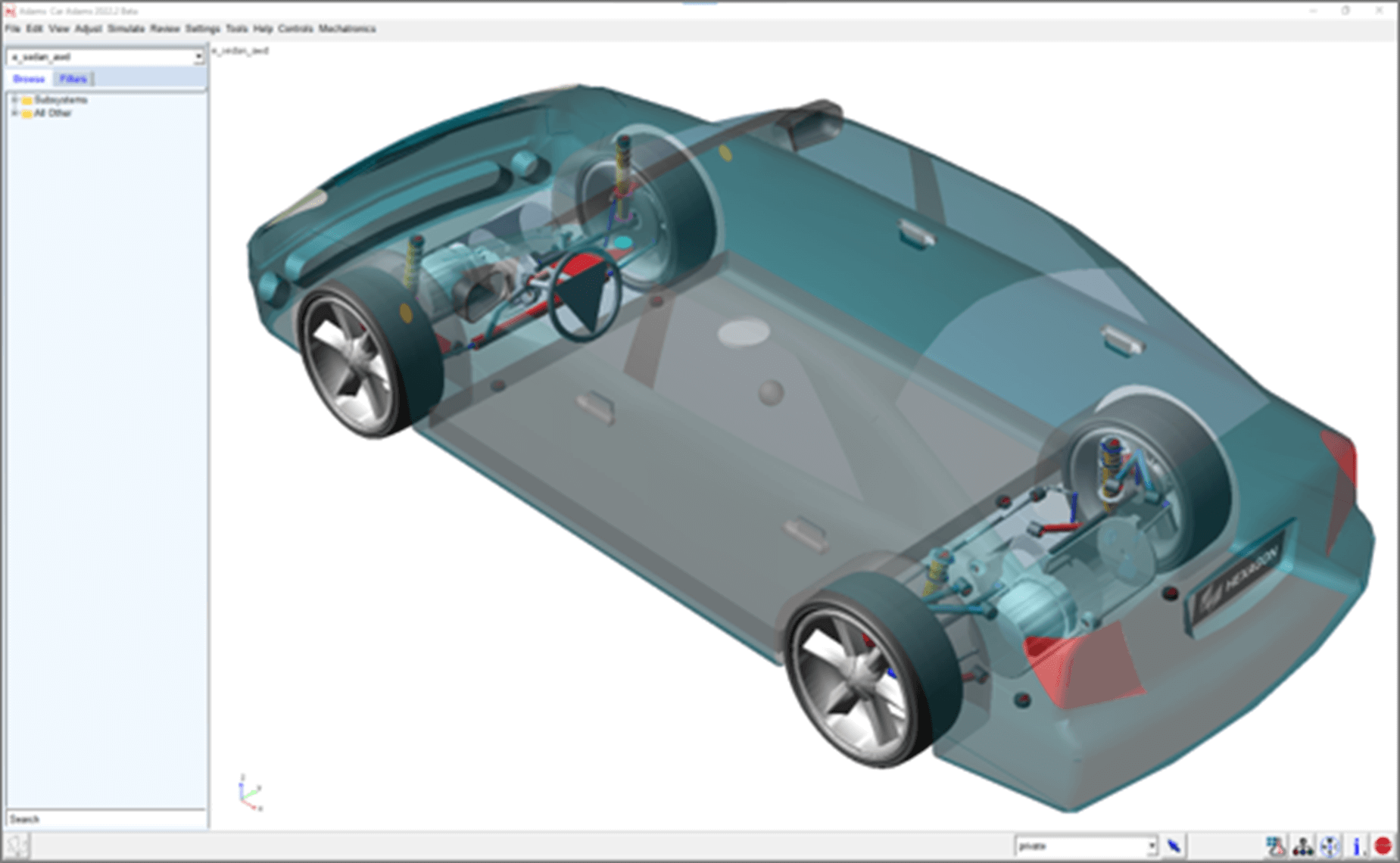

Prevent challenges around system integration and design uncertainties at a stage when you have undetermined layouts and no physical prototypes (i.e., decide between multiple steering and suspension system configurations). Save on time and cost required to build prototypes.

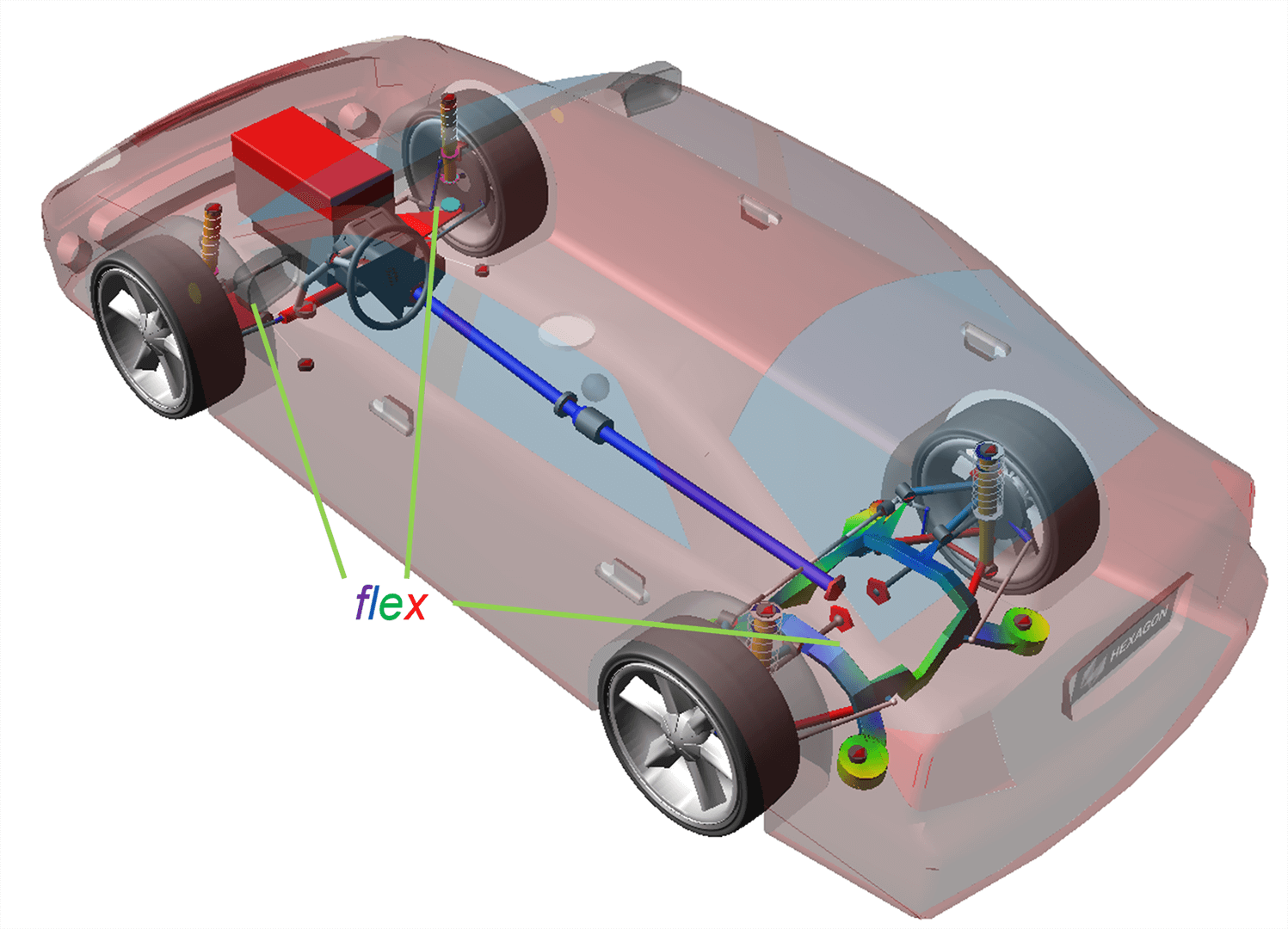

Comprehensive multi-fidelity modelling

Model multiple fidelities (rigid body, flexible bodies) in one place, consider physical interactions during design and feasibility studies, and understand a complex system’s functional behavior.

Computationally accurate and efficient

Adams RT uses the same most trusted Adams solver. It confidently captures life-like high frequency response of critical components with ease and lets the designer experience the real-world feel of driving a vehicle or operating a machine.

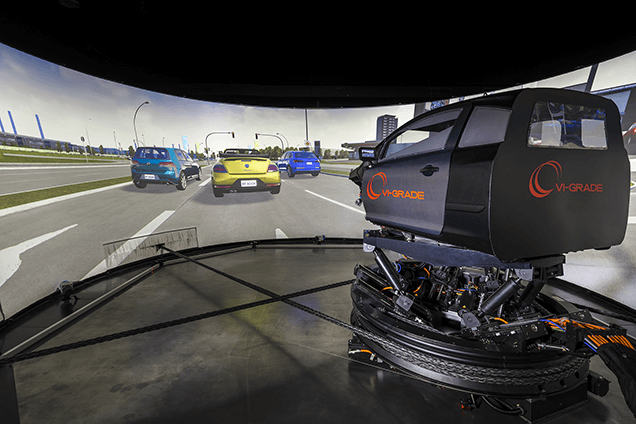

Hardware/Simulators

Adams RT has been tried and tested on industry leading hardware and certified for seamless integration.

Connections via FMU

100% compliant with FMI, to connect to other software packages and to physical hardware to reduce the need for complete physical prototypes during testing.

-

Case studies

-

Case studyFaster testing and virtual validation of access

-

Case studyOptimising washing machine performance

-

Case studyApplus+IDIADA - Enhancing the driving simulator

-

Case studyJLG Industries - Faster testing and virtual validation

-

Case studyFord Motor Company - Reducing Physical Prototyping

-

Case studyMotus Labs

-

Case studyPolitecnico di Milano

-

-

Webinars