Mine Fragmentation Analysis

Manage fragmentation from blast to mill with technologically advanced image-analysis techniques.

Variability in blast fragmentation significantly affects downstream processes, such as mining, crushing and milling. Hexagon’s integrated fragmentation analysis solution can help you manage rock size, minimise variability and increase profitability.

Overview

Optimising fragmentation

Mining promises few guarantees, but reduced ore yield is a certainty if errors are made at any stage of the complex drill and blast process. The potential for wasted energy, time and opportunity costs business more now in an age of declining grades when miners are digging more earth for less ore.

Efforts targeted at optimising the blasting process can pay dividends downstream, reducing costs and energy consumption.

Effective blast design can optimise fragmentation from the run of mine (ROM) ore muck pile to improve productivity and increase site profits through digging, loading, crushing and grinding.

A measure of particle size distribution at each unit operation in the comminution cycle allows engineers to manage blast design more efficiently. They produces fragmentation in the ROM ore most suitable to optimise downstream unit processes to improve mine site productivity and profits.

Hexagon’s real-time fragmentation analysis solution optimises energy factors for each blast.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

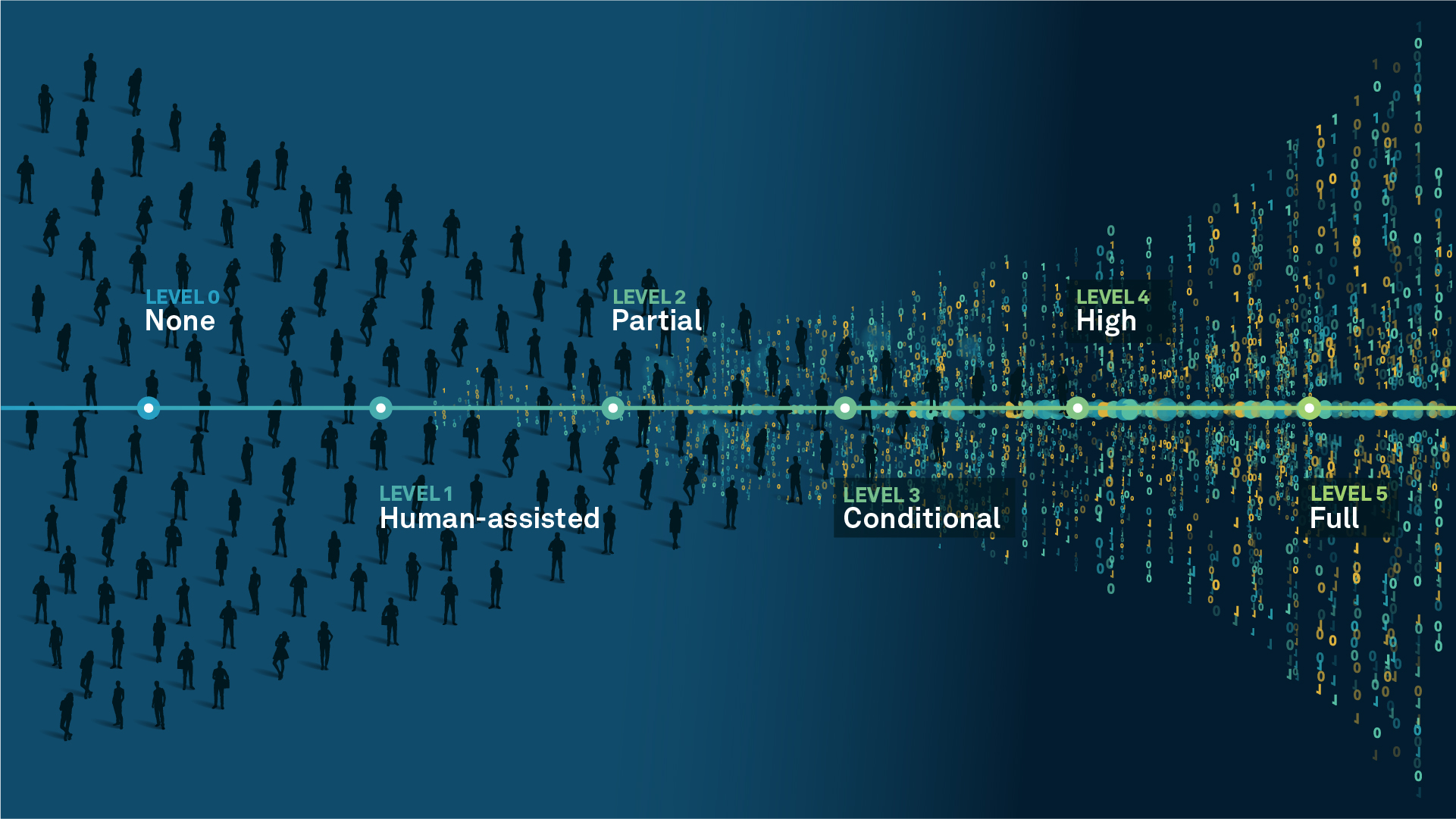

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.