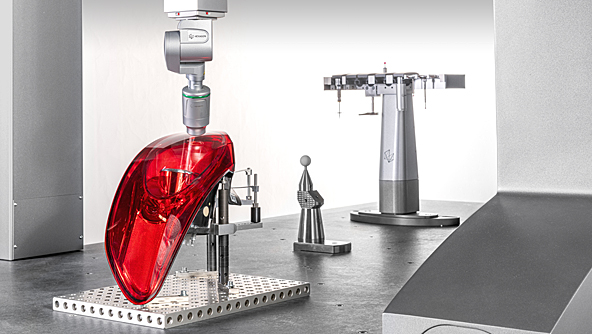

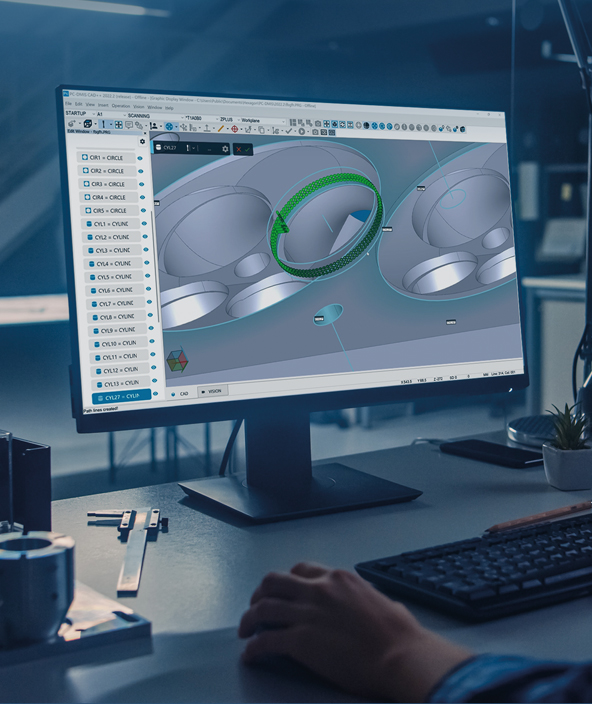

Versatile inspection technology increases adaptability

Leading German manufacturer relies on versatile inspection solutions to adapt to the fast-moving electronic components market

Contact us

Adaptability is essential to success in the electronics market. Especially when supplying high-quality, cost-effective design and manufacturing services to a diverse mix of OEMs that expect very different electronic components to arrive in perfect condition and on time.

It’s a challenging environment and one in which Faist Mekatronic thrives, helped by versatile and scalable inspection technology from Hexagon that can adapt easily to new customer demands.

Faist Mekatronic helps its customers implement creative ideas, with design and manufacturing expertise that includes metal stamping and plastic injection moulding technologies.

With Hexagon’s coordinate measuring machines (CMMs) and inspection software it is possible to accurately inspect features for all kinds of components and assemblies, including the surface profile, flatness, true position, location, angularity, perpendicularity, circularity, symmetry, parallelism.