Aero engine gear and transmission component inspection

Dimensional measurement solutions to support the precise inspection of aero engine gears and transmission components

Contact us

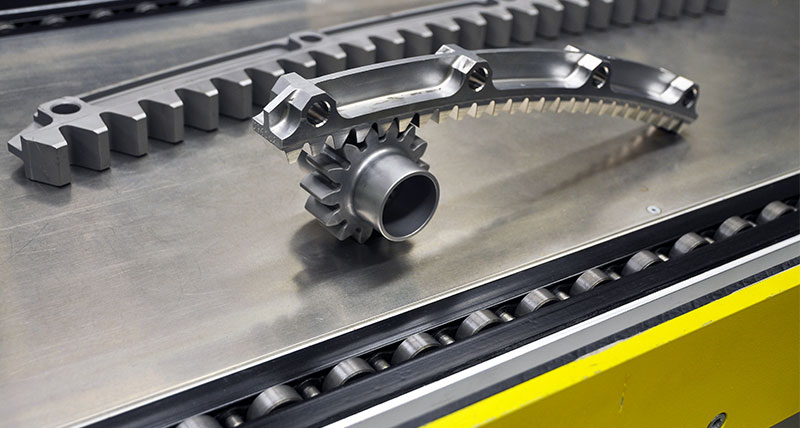

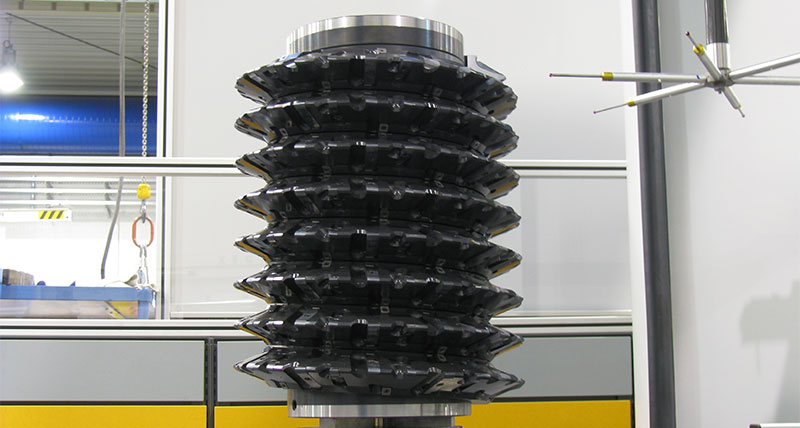

Gearboxes are crucial for transmitting the right levels of power to the different aero engine components. By ensuring that the fan spins slower than the compressors and turbines, gears drive fuel efficiency and reduce noise emissions, enhancing the aircraft’s operation and helping to meet industry requirements.

To ensure smooth operation, gears have to be produced with very high accuracy. Gear teeth need to touch in exactly the right place for an even rotation and equal transmission of force. Uneven teeth gradually wear out; any play in the assembly or meshing eventually reduces the service life of the part and impairs the functioning of the aero engine.

This requirement for maximum accuracy is one of the major inspection challenges. The teeth must be produced to micron levels of accuracy to ensure fit and optimum positional point of contact. The different gear types required, such as planetary gears and curvic couplings, increases the variety of profiles to be measured.

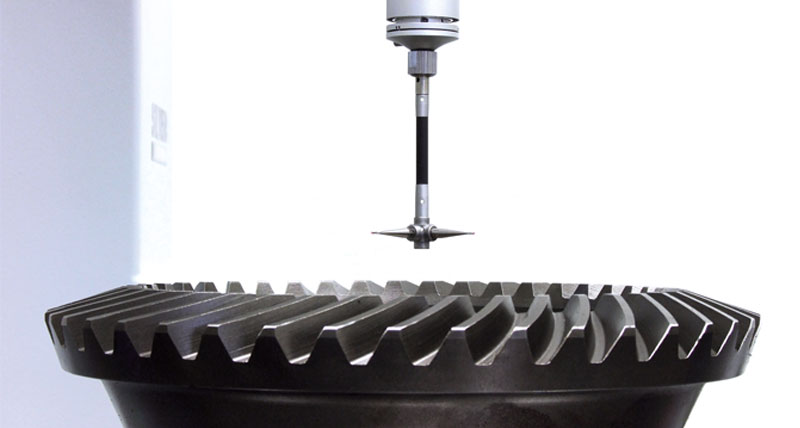

Hexagon offers a selection of measurement solutions for gear inspection. A 3D coordinate measuring machine (CMM) with a highly precise tactile scanning probe supports the high accuracy demands of external, epicyclic and bypass gearboxes. This configuration is ideal for accurately capturing the variety of gear tooth features like top land, pitch surface, bottom land, and flank. A CMM with a rotary table design can also offer high acceleration and positioning speed for reduced gear inspection cycle times.

Software tailored to gear inspection includes a gear measurement toolbox, catering for a full range of types and sizes of gears, as well as offering more measurement and reporting capabilities for different geometries.

To ensure smooth operation, gears have to be produced with very high accuracy. Gear teeth need to touch in exactly the right place for an even rotation and equal transmission of force. Uneven teeth gradually wear out; any play in the assembly or meshing eventually reduces the service life of the part and impairs the functioning of the aero engine.

This requirement for maximum accuracy is one of the major inspection challenges. The teeth must be produced to micron levels of accuracy to ensure fit and optimum positional point of contact. The different gear types required, such as planetary gears and curvic couplings, increases the variety of profiles to be measured.

Hexagon offers a selection of measurement solutions for gear inspection. A 3D coordinate measuring machine (CMM) with a highly precise tactile scanning probe supports the high accuracy demands of external, epicyclic and bypass gearboxes. This configuration is ideal for accurately capturing the variety of gear tooth features like top land, pitch surface, bottom land, and flank. A CMM with a rotary table design can also offer high acceleration and positioning speed for reduced gear inspection cycle times.

Software tailored to gear inspection includes a gear measurement toolbox, catering for a full range of types and sizes of gears, as well as offering more measurement and reporting capabilities for different geometries.

Our solutions

Explore Hexagon solutions for aero engine gears and transmission inspection

Ultra-high accuracy CMMs

The Leitz PMM-C CMM gives you the finest accuracy for high-precision inspection of gearbox features.

Customisable inspection solutions

The multiple capabilities of the GLOBAL S CMM can be tailored for aero engine gears and transmission components.

Gear measurement software

QUINDOS Gears automatically generates measurement paths for gears evaluation according to a range of industry standards.

Case studies

See how Hexagon solutions are used in aero engine gears and transmission inspection

Smoother gear inspection

Discover how gear manufacturer BMT Aerospace enhanced the accuracy and efficiency of its gear inspection process.

Geared for success

Read why Triumph Gear selected a GLOBAL CMM for the inspection of parts including helicopter gearboxes.

Measurement flexibility

Learn how Hexagon partnered with specialist cutting tool manufacturer Ingersoll Werkzeuge to develop a specialised QUINDOS module for tangential hobs.