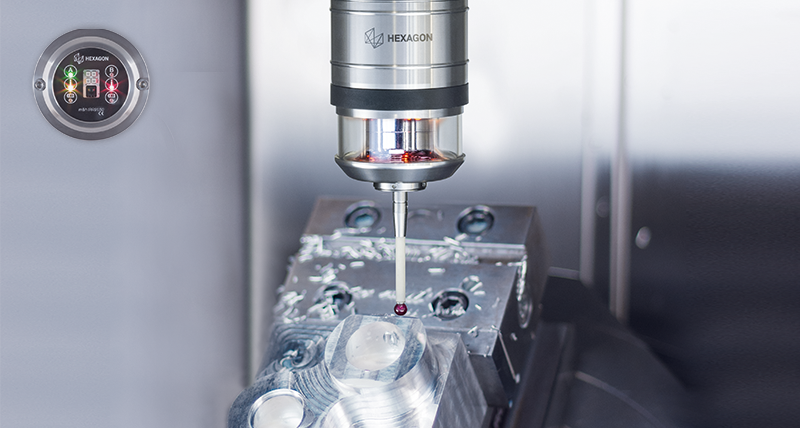

m&h infrared touch probe IRP25.50

m&h IRP25.50 - infrared touch probe of the newest generation

Ready to get started?

The m&h probes of the new generation allow to operate two IRP25.50 at the same time with only one IRR91.50 receiver. For example, this is suitable for simultaneous measurements on both spindles of double-spindle machines.

Application:- Determination of workpiece zero point

- Determination of workpiece position

- Control measurement of workpiece dimensions

- Simultaneous measurement on double-spindle machines

- The future-proof IRP25.50 supports different measuring mechanisms

- P41.00 Measuring unit with three-leg system

- MY21.00 Measuring unit with hemisphere system

- TP44.10 Temperature measuring unit

- Patented dual-probe technology from m&h

- The HDR+ technology (high data rate+) rules out disturbances due to extraneous light

- ITE technology (Intelligent Trigger Evaluation) - with high-speed pre-positioning

- Chameleon technology - Supports third-party protocols of competitors

m&h IRP25.50

-

Features & benefitsMODULAR PROBE SYSTEM

Features:

- Can be modified simply by screwing in

- System basis supports different m&h measuring mechanisms

- One system basis for a wide range of applications

- Reverse measurements in Z+

- Carbon extension

- Probe cross

- Temperature probe

Benefits:

- Different measuring mechanisms for one system basis

- Cost-effective for various requirements

- Storage cost savings thanks to flexibility

- Future-proof for new m&h measuring mechanisms!

HDR+ (HIGH DATA RATE+) - TECHNOLOGY

Features:

- Different from worldwide line frequencies of 50 Hz or 60 Hz

- Modulation frequency of 455 kHz

- Extremely high data rate for secure information transmission

- Homogeneous and true 360° directional characteristics through innovative design with mirrored surfaces

- Extremely high signal range

- Optimized battery consumption without loss in process reliability

- Bidirectional activation thanks to separately coded ON/OFF signal - naturally with HDR+ performance

Benefits:

- No interference from ambient light

- Safest infrared transmission

- Improved HDR+ technology

- Optimized energy consumption with increased transmission power

ITE-TECHNOLOGY - INTELLIGENT TRIGGER EVALUATION

Features:

- Evaluate trigger signals

- Filtering machine vibrations and shocks

- No increase of the trigger force required

- No loss of precision

- No measuring errors due to incorrect switching

- Shorter cycle times by fast pre-positioning

Benefits:

- Shorter cycle times without loss of process reliability

- With high-speed pre-positioning (up to 50 000 mm/min) thanks to ITE technology

- One Touch Strategy for fast and precise probing (up to 2,000 mm / min)

CHAMÄLEON - TECHNOLOGY

Features:

- Supports third-party protocols of competitors

- In case of a probe crash, easy and inexpensive alternative

- Simple protocol setting

- No conversion required when changing to m&h

Benefits:

- No machine conversion or receiver change necessary

- Easy probe exchange

-

Related informationDUAL PROBE TECHNOLOGY

Features:

- Measure simultaneously with two m&h IRP25.50s and one m&h IRR91.50

- In the case of double-spindle machines, measure simultaneously on both spindles

- Separately defined infrared signals for extremely secure transmission

- Dual probe technology, naturally with HDR+ infrared transmission

- Technologically unique and patented by m&h

- Less wiring required than for radio systems

- Process-reliable thanks to infrared transmission rather than the radio wave touch probes used up to now

Benefits:

- Clear reduction in cycle times thanks to simultaneous measurement on both spindles

- Optimizes and supports your lean production

- High-end technology - only at m&h

PROCESS-RELIABLE ACTIVATION METHODS

Features:

- Patented pullstud activation

- Patented water-switch activation

- Mechanical HSK activation

- Separately coded ON/OFF infrared activation

-

Technical data

Unidirectional Repeatability max. 1 μm (2 Sigma) with 50 mm stylus and 254 mm/min probing feedrate Recommended Probing Feedrate Max. 2000 mm/min Sensing Directions ±X, ±Y, -Z Maximum Stylus Overtravel PP41.00 - XY ±12,5°; Z-6 mm MY21.00 - XY ±14°; Z-4,5 mm

Trigger Force with 50 mm Stylus PP41.00 - XY = 0,3 - 1,4 N; Z = 2,5 - 12,5 N

MY21.00 - XY = 1 N; Z = 6 NPower supply 1x 9 V Battery, Block, 6LR61, Lithium: 1200 mAh, Alkaline: 550 mAh

Weight without Shank ca. 920 g Temperature Range Operation: 10°C - 50°C, Storage: 5°C - 70°C

Material Stainless Steel, POM Sealing IP68: EN60529 -

Downloads

-

Buy machine tool accessories online

Buy machine tool accessories online

Identify your spare parts with confidence and benefit from fast UPS delivery