The world goes digital

A passion for 3D scanning and the support of high-precision structured light scanning technologies what’s needed to become a one-stop 3D service provider

Contact us

“Since I was a student, I’ve had a passion for 3D scanning, 3D scanners and 3D services in general,” says Paweł Woźniak, Chief Technology Officer at B3D and one of the company’s founders. “Already at that time I was convinced that this is the technology of the future. Our world goes digital – virtual reality, augmented reality – we are already doing 3D scanning for that. The Fourth Industrial Revolution is digital and we are happy to be a part of it.”

“Since I was a student, I’ve had a passion for 3D scanning, 3D scanners and 3D services in general,” says Paweł Woźniak, Chief Technology Officer at B3D and one of the company’s founders. “Already at that time I was convinced that this is the technology of the future. Our world goes digital – virtual reality, augmented reality – we are already doing 3D scanning for that. The Fourth Industrial Revolution is digital and we are happy to be a part of it.”

One building block to the company’s success was the acquisition of a SmartScan structured light scanner from Hexagon. “The company was founded in 2013, but it was with the purchase of the SmartScan in 2015 that we really started our business,” confirms Woźniak.

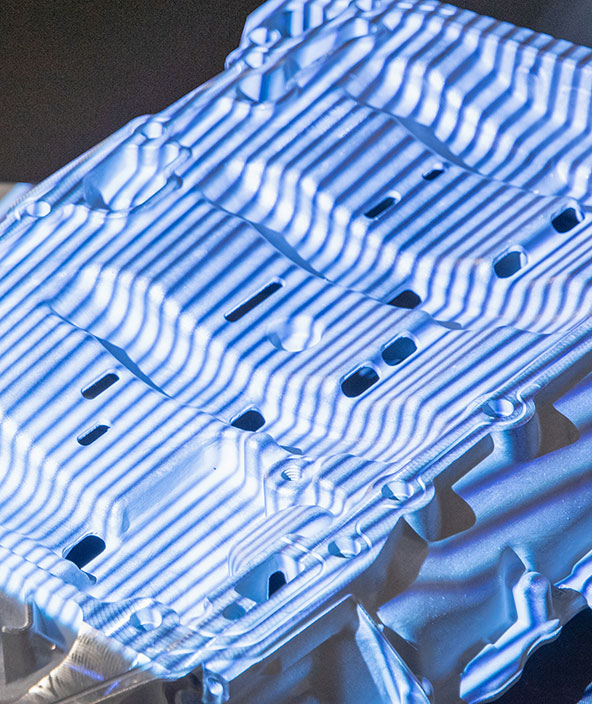

When high precision is required, SmartScan comes in. It provides the highest scanning quality that we offer our customer.The SmartScan is used at B3D when high-precision measurements are required, such as in the inspection of injection moulded parts or the injection moulds themselves, as well as when inspecting mechanical components or iron castings. “When high precision is required, the SmartScan comes in. It provides the highest scanning quality that we offer our customers,” explains Woźniak.

To do this, the structured light scanner projects a light pattern onto the surfaces to be measured, which is captured by the SmartScan’s two 8-megapixel cameras.

To do this, the structured light scanner projects a light pattern onto the surfaces to be measured, which is captured by the SmartScan’s two 8-megapixel cameras.

The captured images are evaluated in the dedicated OptoCat scanning software and used to derive highly precise information about the measured object.

The great advantage of the SmartScan is that it measures the entire visible surface of the measurement object in one pass and thus ensures an exceptionally high measurement point density. This not only provides extremely precise measurement data, but also a particularly high degree of resolution, thus enabling the object to be digitised with an accuracy of to within a few microns.

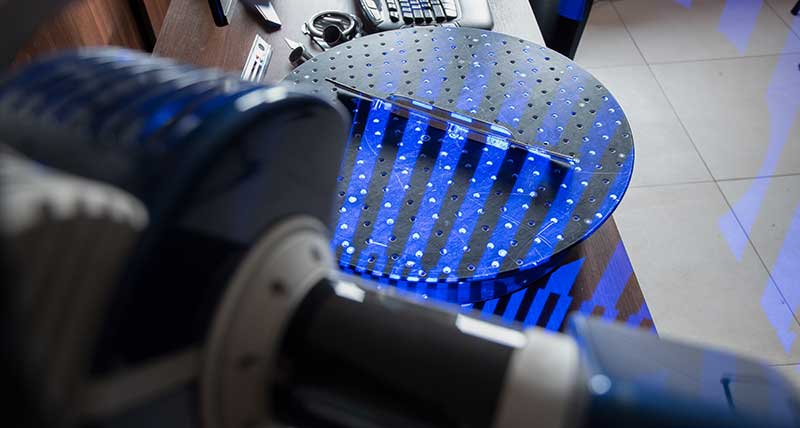

The scanning process is very fast and even semi-automated thanks to the use of a turntable on which the object to be measured is placed. With such a setup, the entire measuring process takes between a few seconds and a few minutes and is completed as soon as the images have been taken from all sides of the object. “This is also an important factor for us,” says Woźniak. “Quality control in particular is an area that requires a fast response from us.”

The scanning process is very fast and even semi-automated thanks to the use of a turntable on which the object to be measured is placed. With such a setup, the entire measuring process takes between a few seconds and a few minutes and is completed as soon as the images have been taken from all sides of the object. “This is also an important factor for us,” says Woźniak. “Quality control in particular is an area that requires a fast response from us.”

In addition to the SmartScan structured light scanner, B3D also uses other measuring systems from Hexagon. For example, a Leica RTC360 laser scanner is used whenever very big objects such as buildings need to be digitised. “In the future, we would like to cover the entire spectrum of 3D services and the SmartScan is an important brick in this strategy,” reports Woźniak on the company’s future plans. “We would also like to acquire a portable measuring arm with a laser scanner from Hexagon, for simpler inspection tasks and in particular the digisation of shiny and glossy surfaces. Then we would be able to offer our customers the full range of 3D scanning options, at every level of precision.”

Due to their close relationship with Hexagon, B3D was also among the first customers to test the new SLS-PW Plugin – a software add-on for PolyWorks that allows comprehensive control of all Hexagon’s structured light scanners through the PolyWorks software environment.

Due to their close relationship with Hexagon, B3D was also among the first customers to test the new SLS-PW Plugin – a software add-on for PolyWorks that allows comprehensive control of all Hexagon’s structured light scanners through the PolyWorks software environment.

Until now, B3D has used PolyWorks for comparisons with CAD models. For this purpose, the scan data captured by the SmartScan and processed into an STL in OptoCat was then imported into PolyWorks for analysis. Thanks to the new SLS-PW Plugin, the exchange of data is now completely unnecessary.

This bundling of workflows into just a single platform ensures a considerable gain in efficiency. Inspection times are shortened because the export and import of measurement data between different programmes is no longer necessary, while the need for training is also reduced.

In the future, we would like to cover the entire spectrum of 3D services and the SmartScan is an important brick in this strategy.Woźniak sits down at the computer with the new software and is immediately enthusiastic. “This is a terrific development. Customers will be happy because it will speed up the entire quality control process. You simply do everything in one software. And it’s totally simple too.”