Inspection of aircraft pylons, winglets and fairings

Dimensional measurement solutions to accurately inspect curved panels including aircraft pylons, winglets and fairings

Contact us

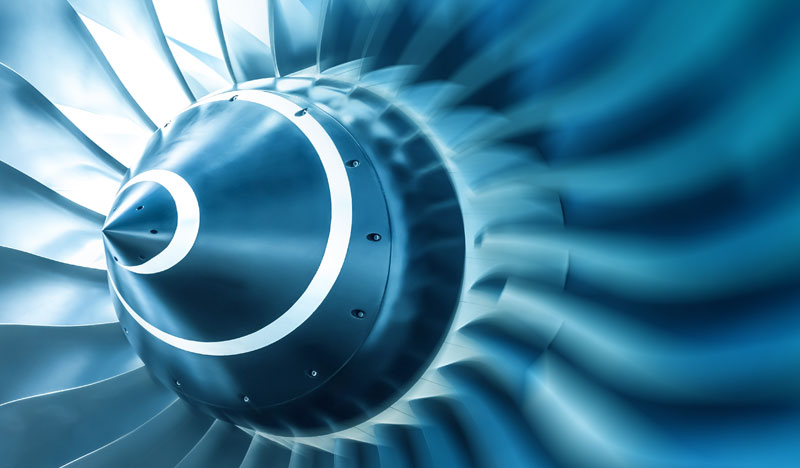

Winglets and fairings play an essential role in the aerodynamic performance of an aircraft, while the pylon performs the crucial task of holding the aircraft engine in place.

As with every element of an aircraft’s structure, it is imperative to ensure winglets, fairings and pylons comply with design standards. But the complex, curved surfaces of these mid-sized aircraft parts make them time-consuming and tricky to inspect. Not only do they need to be measured from every angle, they are manufactured with advanced composite materials that require careful handling, making them difficult to manoeuvre within the measuring area.

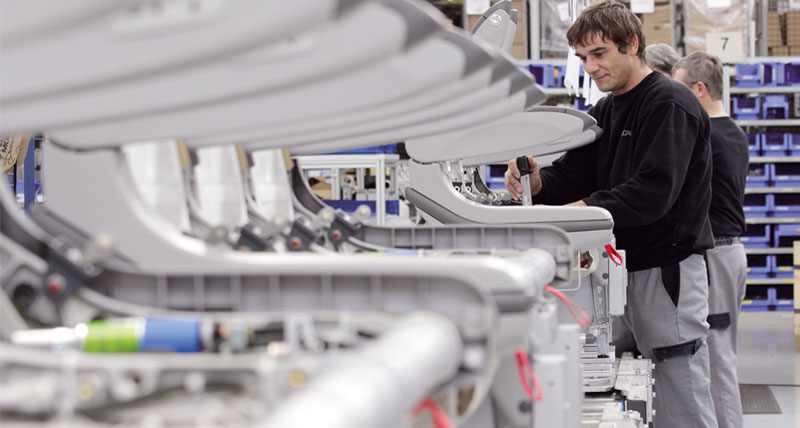

Airframers typically use skilled operators to inspect pylons, winglets and fairings, but with the right measurement tools, manufacturers can enhance productivity by simplifying and automating the process while guaranteeing precision.

Hexagon equips the aerospace industry with CMMs, portable measurement solutions and metrology software options that combine flexibility and accuracy to inspect curved aircraft parts even within challenging workshop environments.

As with every element of an aircraft’s structure, it is imperative to ensure winglets, fairings and pylons comply with design standards. But the complex, curved surfaces of these mid-sized aircraft parts make them time-consuming and tricky to inspect. Not only do they need to be measured from every angle, they are manufactured with advanced composite materials that require careful handling, making them difficult to manoeuvre within the measuring area.

Airframers typically use skilled operators to inspect pylons, winglets and fairings, but with the right measurement tools, manufacturers can enhance productivity by simplifying and automating the process while guaranteeing precision.

Hexagon equips the aerospace industry with CMMs, portable measurement solutions and metrology software options that combine flexibility and accuracy to inspect curved aircraft parts even within challenging workshop environments.

Our solutions

Explore Hexagon solutions for the inspection of curved panels in the aerospace industryGantry CMMs

The large-volume DEA DELTA SLANT gantry CMM excels in the accurate inspection of larger machined parts in workshop environments.

Handheld laser tracker based probing

The portable Leica T-Probe provides a quick yet accurate way to check critical reference points on final subassemblies for errors in assembly or alignment.

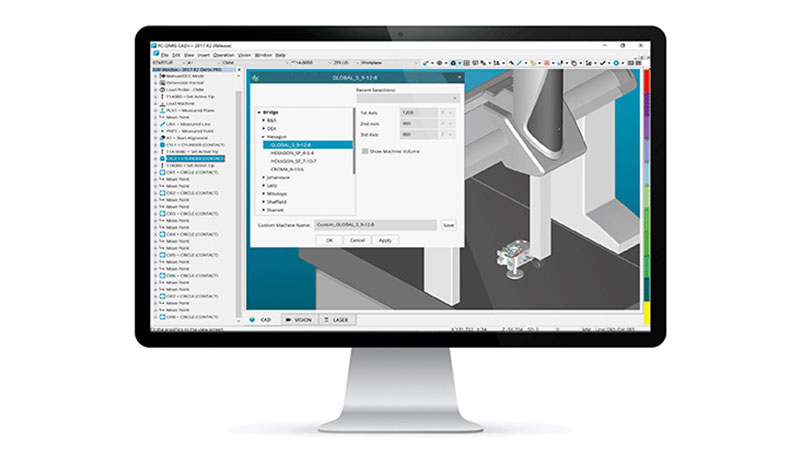

Intuitive metrology software

PC-DMIS is the world’s leading measurement software and makes it easy to measure the large, complex machined parts required by the aerospace industry.

Case studies

See how Hexagon solutions are used to inspect aircraft pylons, winglets and fairingsAircraft pylon inspection productivity

Find out how Airbus improved the productivity of its jet engine pylon inspection process using a dual laser tracker setup from Hexagon.

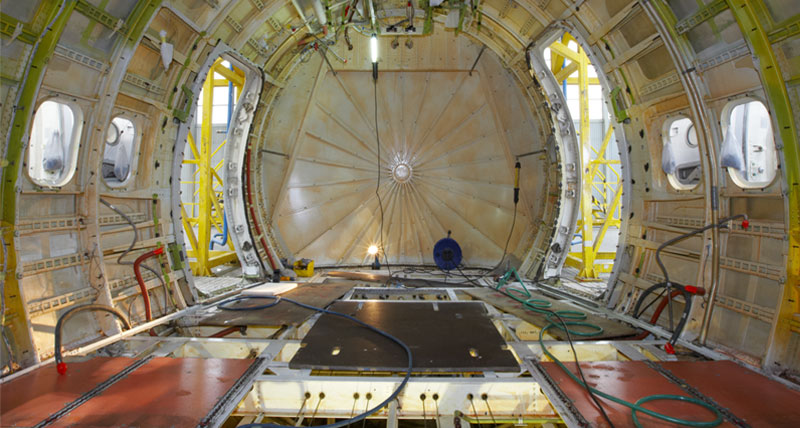

Premier Composite Technologies

Read how Premier Composite Technologies uses Hexagon’s portable measuring systems to check moulds and final composite parts.