Enabling reliable aircraft structures with generative design

MSC Apex Generative Design enables design project to reduce two parts into one, and cuts the maximum stress in half

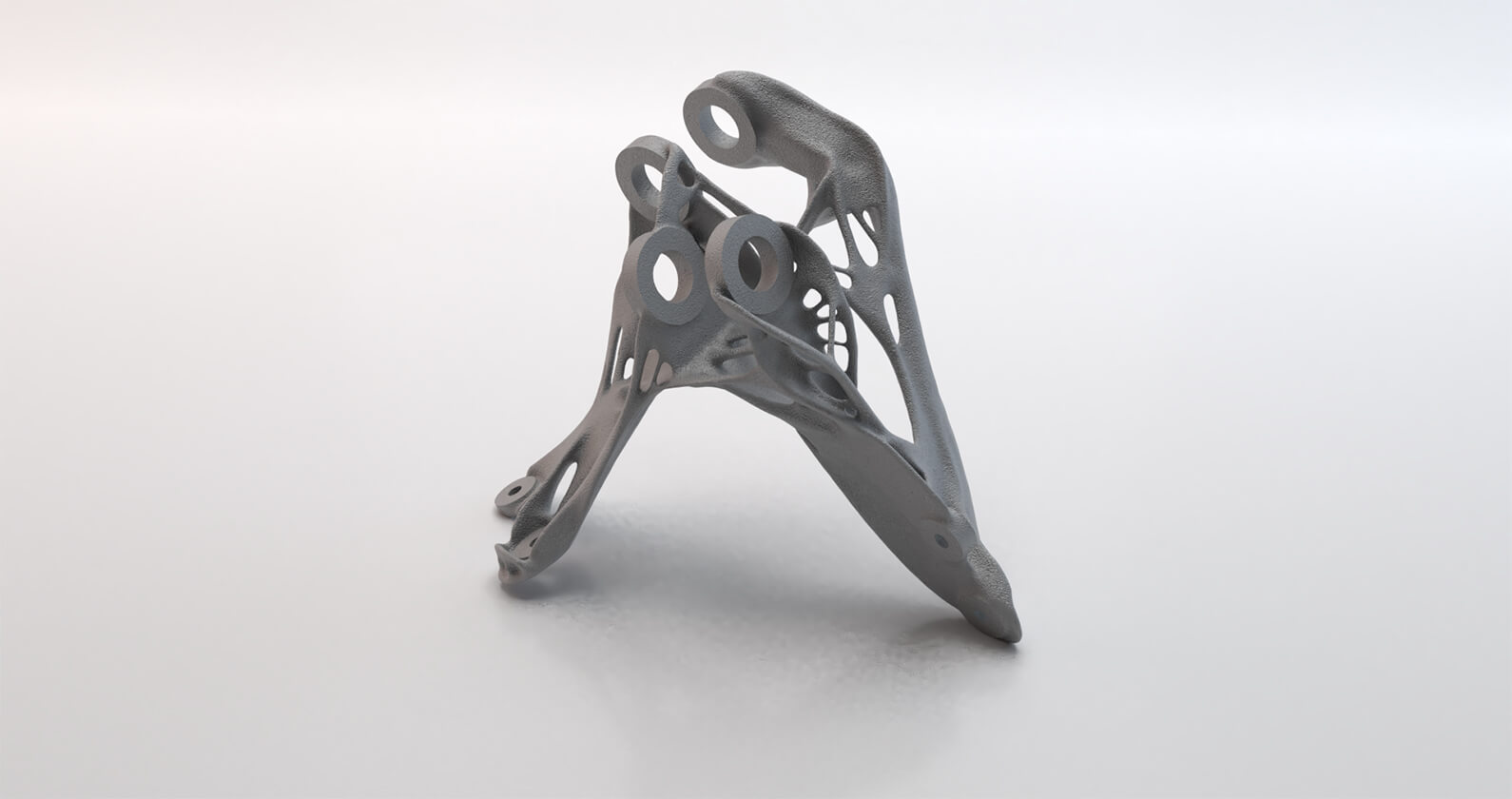

Integrated, optimised part design for robust, lightweight design

Researchers at the University of Paderborn replaced the two-part assembly with one single part, reduced weight by 63%, and cut the maximum stress in half. One of the most beneficial aspects of MSC Apex Generative Design was the innovative, easy-to-use interface, which did not require an expert in Finite Element Modeling (FEM).

The aerospace industry demands high-quality and reliable components. Additive Manufacturing has enormous potential for creating high-tech parts, but it requires a new breed of designs that are function-oriented with optimized and purpose-oriented geometries. MSC Apex Generative Design’s function-oriented component optimization can help achieve this.

This case study shows an aerospace bracket where the optimisation process started with the original part’s geometry with a resulting optimised geometry that was geometrically and mechanically sound with the final iteration. To validate the optimized design, physical testing was conducted by mounting the part in a tensile test machine.

Fill in the form and directly access this case story!