Creating simplicity in metrology-assisted assembly

Contact us

ARGON Measuring Solutions played a vital integration role in development of a ground-breaking metrology-assisted assembly solution for the Siemens Gamesa facility in Cuxhaven, including developing the project’s custom-made front-end software solution. Founder and owner of ARGON Geert Creemers told us all about the project and ARGON’s driving “coffee-machine principle”.

Thanks for meeting with us Geert. So, what are ARGON all about?

We’re a measurement integrator, so we take technological breakthroughs, hardware and software, and we turn that into a workable shop-floor solution. We coined the term “coffee-machine principle”, because we want our systems to be used that easily from within production – just press a button and go, just like a coffee machine.

We believe strongly that metrology will really move more and more into the manufacturing environment, as opposed to in the past where is has traditionally been focused on the measurement room and laboratory conditions. In the future these processes will more and more become part and parcel of the manufacturing process itself.

The role that we see for ourselves is that in the past you could sell to a measurement room, you could sell the box, unpack it, give training and people continue with it, but increasingly such solutions are being used by operators who don't know Hexagon hardware or who aren’t already familiar with SpatialAnalzer or other metrology software – they see metrology as being just another tool, like a screwdriver so to speak. So the solution needs to be like that, as simple as a screwdriver almost

And this is what the vision is for many companies that say they want to invest in metrology. They’re looking for that simplicity of operation, but also for a system that pays off by making their manufacturing or assembly processes more accurate, more reliable, and in that way they can create a return on investment.

How did you come to be involved with the Flexible Stator Assembly Center (FSAC) project with Hexagon at Siemens Gamesa?

The Hexagon team was already in touch with Siemens Gamesa about the project, and together they had developed this idea for a combined photogrammetry and laser tracker solution. I think they soon realised that this was a case where they could sell these products, but it needs to be part and parcel of the production line – if they were to just send them the photogrammetry equipment and an Absolute Tracker, it simply wouldn't work. The solution needs to be part of a bigger project to really be embedded in their workflow. So that’s where we were brought in – a Hexagon team member we had worked with previously on other projects recommended us as a group with experience in exactly this sort of integration project.

So I remember that in November 2018 I got the call from Hexagon, and then we had a first preliminary call with Siemens Gamesa, and they were quite impressed with what we had done previously with Hexagon. They said, “this is exactly what we need, tell me when you can deliver”. And so that was how we got involved. There was then the first site visit and we realised that this was something really up our alley.

So you and your team had some history of working together with Hexagon, and this project was really building on that?

We have done some work with Hexagon in the past. One example is a project in France, where we did some nice work together making an assembly process for the wing box of an aeroplane, that we streamlined. We took an Absolute Tracker system and SpatialAnalyzer in that case, and we made a “coffee-machine principle” human-machine interface that guided the workers through the assembly process. In the end, whether you would be the worker or I would be the worker, if they would call us and say, “here you need to do the work”, with two hours training you could; you would know enough and you would be able to do that work and do these measurements without any problem.

That sounds really impressive. The software must be doing a lot of the work that the operator previously needed to do.

Yes, for instance to achieve that you need to build in all sorts of accuracy checks. When something is not right, normally you get an error message and you can have hundred's of buttons and you don't know which one to press to continue. So if you want a simplified system, you need to have very efficient error handling to allow the person to restart this procedure in an easy way.

Can you tell us about your team’s involvement in the FSAC project at Siemens Gamesa?

After the Hexagon and Siemens Gamesa teams came up with this idea of combining the 3DArena photogrammetry system with the laser tracker, they quickly realised that it's actually a little bit complicated and it's an untested combination of technologies. They decided to go through a feasibility study, and that was the point at which we were invited to become involved.

On the one hand, the feasibility study focused on the technical side from Hexagon, looking at whether the required accuracies were achievable. And on the other hand, for us it was really a time to develop an idea in terms what the broader parameters for the functioning of the human-machine interface would have to be and what type of integration they would need.

That was something that was really undefined for us in the beginning. This was a big project and the specification was pretty much, “deliver us a system that can measure”. There was a little bit more detail than that, but that was really about it. We have been involved in other big projects where they give you a big document where they really have described almost everything, down to which screws you need to use. But this was a much more freeform project kick off, which made things both very exciting and very challenging. They liked our idea of the coffee machine principle, of delivering a system that needs to be very simple at the operator level, but we were very free to define what that system would look like.

So what exactly have you delivered for Siemens Gamesa? What did your part of the system end up looking like?

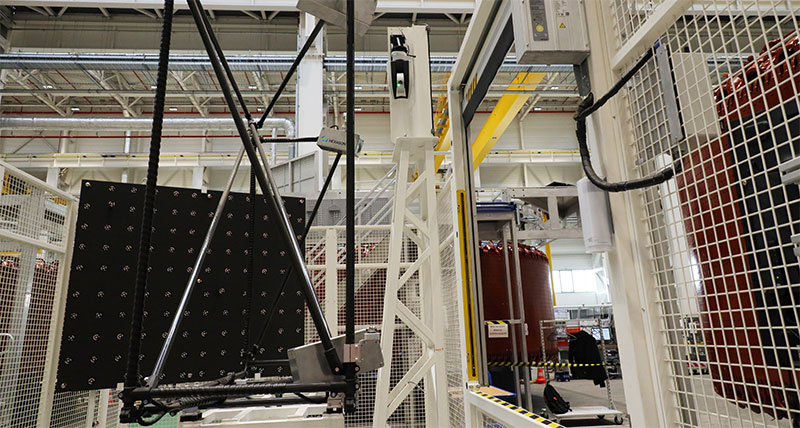

What we did was to make two things. On the one hand, we made a self-measurement cell. So that's the scope of our physical delivery. We created a cell with a robot that could automatically perform the calibration of the 3DArena and the Absolute Tracker system. That gave us this automatic setup process, where you can just press Start/Stop button and it just works.

The robot goes through this programmed complex routine of movements while holding a scalebar and that’s how the 3DArena setup is calibrated. We have the 3DArena cameras mounted on a turntable, so when they need a full calibration they’re oriented towards the robot, and the rest of the time they are pivoting back and forth between the stator and the visual alignment panel that is checked before every new segment measurement begins. This was a process defined by Hexagon and the Siemens Gamesa engineers, and we produced the working, automated system that carries out what they needed.

Our second deliverable was really the software, which is this human-machine interface that steers the entire process – the direct interface to the operator. We built this whole software layer, which takes care of a large part of the measurement calculation process internally – something that the team were previously doing essentially manually, in Excel.

It’s really a custom software application that we created specifically for this use case. That was a real challenge, making everything it work in terms of the necessary communication with the 3DArena and Absolute Tracker software and with the SpatialAnalyzer measurement software, and then having our simplified interface built on top as the final user-facing layer.

So we built the full process into our custom software, so that in the end your operators can just position the stator and segments and then just say start. They do the first measurement, make the adjustments the software tells them to make, then straight to the second segment, and then the next. Measurement from the 3DArena-Absolute Tracker system is in real-time, so everything happens really quickly. The system is really ready for the operators to use with a very simple interface that aims to completely avoid any confusion. And this is what I call the coffee machine principle interface.

It sounds like you were able to deliver exactly what Siemens Gamesa were looking for.

Now we are in a situation where the client is, I think, very happy, with both Hexagon and ARGON. For Siemens Gamesa it’s really a very critical strategic project, in the sense that the air gap of the turbine really is one of the key parameters that determines the performance of the turbine.

In the past they just did some measurements, it took them a very long time and even then the reliability of the measurements was not so good. So I think now they will have something that goes quicker and that’s more reliable. And we’re in process of working with the Siemens Gamesa team on other projects that take this metrology-assisted assembly concept even further into their production process.

So yes, I think we can call this a success story.