‘Off-the-shelf’ automated shop-floor inspection for aerospace

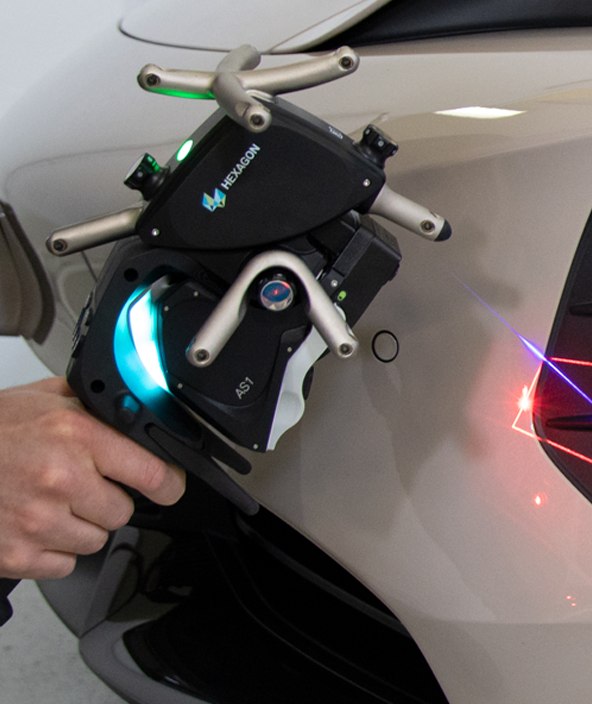

Hexagon laser tracker technology powers a ground-breaking automated inspection package for advanced aerospace manufacturing.

Contact us

Having worked with Hexagon and its subsidiaries for over a decade, INSPHERE has a well-established history of using Hexagon metrology solutions to enhance advanced manufacturing, particularly in the aerospace sector. The company provides contract measurement services and expert measurement training, alongside developing custom measurement installations.

INSPHERE has worked with a wide range of customers across a variety of sectors, from Airbus and GKN in aerospace to Vestas and GE in energy, as well as prominent research organisations such as the National Composites Centre and the National Physics Laboratory.

Automation integration is a key focus for INSPHERE. This growing segment has seen them become the driving force behind a large number of robot-based measurement installations powered by Hexagon metrology technology. A recent development in this area has seen INSPHERE create the HYPERSCAN concept – an in-line non-contact automated inspection system in a standardised cell configuration.

“HYPERSCAN is an innovative ‘off-the-shelf’ solution for automated shop floor inspection,” said Ben Adeline, CEO at INSPHERE. “It’s ideally suited to large components where the use of a traditional CMM would be impractical due to environmental conditions and too expensive due to size.”

“HYPERSCAN is an innovative ‘off-the-shelf’ solution for automated shop floor inspection,” said Ben Adeline, CEO at INSPHERE. “It’s ideally suited to large components where the use of a traditional CMM would be impractical due to environmental conditions and too expensive due to size.”

Conventional hand-tool oriented inspection methods are time-consuming and labour-intensive operations with high potential for mistakes when recording results. On the other hand, automated metrology solutions traditionally utilise coordinate measuring machines (CMMs) – commonly gantry-based with three-to-five axes and a tactile touchtrigger probe. They tend to be somewhat inflexible and are impractical when the inspection of large components needs to be performed quickly, close to production and with noncontact measurement technology.

The HYPERSCAN concept was built on the development of a custom automated system to deal with these exact challenges for leading aerospace manufacturer GKN. “HYPERSCAN was born out of the fact that GKN had been looking for a better solution than CMM and hand tool measurement for their ribs,” explains Craig Davey, COO at INSPHERE. “They were doing key acceptance dimensional checks on their ribs on the shop floor using micrometers, height gauges, standard hand tools. If there were any issues, they’d send the rib for a full CMM check, which takes a couple of hours and is in a different building and is a bit of a hassle – it causes a big bottleneck. And it means that if they’ve got a machining problem, they don’t find out until a week later when they’ve made a bunch of ribs on a worn tool, for example, and all their holes are the wrong size.”