Mine Equipment Maintenance

Extend mine equipment lifetime by identifying machine health trends in real time.

Increase machine availability and up-time

Hexagon helps minimize out-of-warranty repair costs and gain greater insight into unexplained machine system faults.

By identifying machine health trends in real time, Hexagon’s mine equipment maintenance technology empowers you to increase machine availability and maximise your up-time. Insight into machine information allows you to extend durations between servicing vehicles, helping your operations’ bottom line.

Overview

Predict and prevent

Mines are paying for machines with far more sensors than ever before, but that exponential data isn’t always converted into actionable information.

Equipped with Hexagon’s platform of servers and data-loggers, mine equipment maintenance and operations staff in the office and in the field can extend the life of mobile equipment by improving efficiencies that minimize equipment down-time.

The solution can be used to retrofit OEM-agnostic platforms for connecting onboard data logging, telemetry and messaging. On-board alerts can be synchronized with the office, dispatch, reliability engineering, and maintenance centers.

This level of predictive maintenance enables repair engineers to plan and prevent for down-time and lost revenue. Equipment runs longer, keeping production targets on track while avoiding additional costs on repairs and maintenance.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

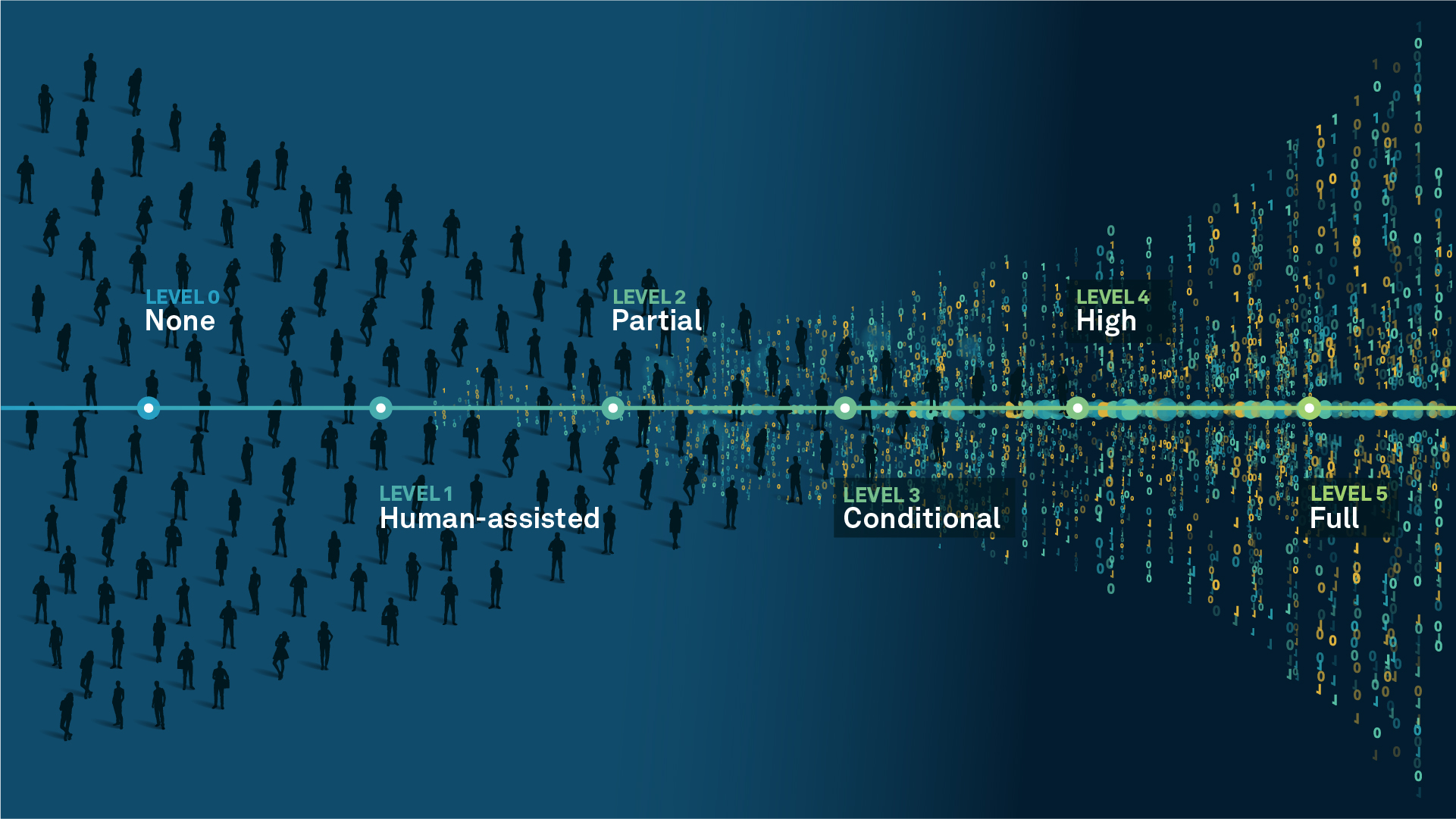

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.