Prototypes processes and prince regent

Bosch and Siemens Home Appliances - Germany

Contact us

For sweet-tooths, the research and development centre at Bosch Siemens Hausgeräte (BSH) sounds like a „Land of Cockaigne“: hundreds of cakes are baked there every day. What the test kitchen is to travellers in this medieval mythical land of plenty, the measuring room at BSH is to metrology technicians: a Leitz Reference Xi high-precision coordinate measuring machine in an air-conditioned room ensuring the quality of the prototypes and initial samples of ovens, built -in hobs and microwave appliances.

An enormous number of ceramic hobs, ovens and microwave appliances are tested at the BSH facility in Traunreut, Bavaria. The factory manufactures 800 different models of built-in hobs, 400 ceramic hobs and 40 microwave appliances. Sheet metal is formed into ovens, electronic parts wired up, doors hung, edge trim frames and other decorative elements attached. The happy hobby chef can delight in an almost infinite diversity of functions and designs. From XXL format ovens through self-cleaning variants to cooking by autopilot, there is every possible feature to make life easy in the kitchen.

Progress takes down tolerance barriers

„The design and technology of our ovens and hobs are continuously changing and improving,“ confirms Florian Huber, Quality Manager Systems. „At the same time the tolerances of individual components are becoming tighter and tighter.“ Increasing diversity, higher accuracy requirements, larger product dimensions. BSH was reaching the limits with its existing coordinate measuring machine. A new solution for measuring prototypes and initial samples was required.

Ingredients for process approval

„We decided in favour of a Leitz Reference Xi because this coordinate measuring machine offers the best price-performace ratio, the required measurement volume and the necessary dynamics. Increased concentration on processes goes hand in hand with higher demands on procedures for process approval. To be able to cover these higher demands, we required a more powerful measuring machine,“ says Huber. The accuracy of the Leitz Reference Xi is MPEE = 1.8 + L/350 microns, i.e. it can measure a length of 1 metre to an accuracy of only 4.7 microns. The LSP-X5 probe head captures 1000 measured points per second.

Accuracy, speed, size

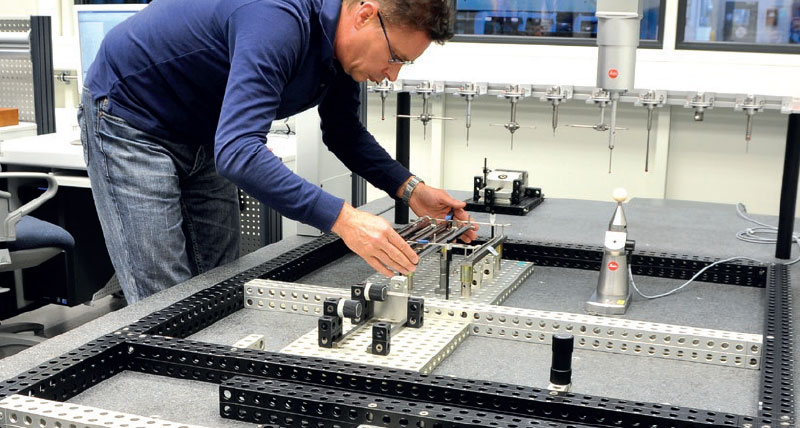

The Leitz Reference Xi is perfect for the requirements of BSH: with a measurement range of 2200 x 1200 x 900 millimetres (X/Y/Z), it also offers sufficient volume to capture the dimensions of the prototypes and initial samples for the new XXL oven. The extended measuring table has enough mounting space to accept several parts on pallets and measure them all in one measuring process. This feature is particularly beneficial to the company for process capability analyses. „Although we could certainly manage to do this with our existing measuring machine, it was a much more elaborate process. Thanks to the high accuracy and the generous measurement range the Leitz Reference Xi, we have much greater flexibility,“ confirms Huber.

Multifunctional measuring room

The measuring conditions are also more satisfactory. The new measuring room was designed by Hexagon Metrology. „The capacity of our previous, smaller measuring room was fully taken up as we had substantially expanded our machine shop,“ explains Huber. In addition to the tactile Leitz Reference Xi we have another stationary coordinate measuring machine, a multisensor measuring machine, a portable measuring arm and a white light sensor on our inventory. There is enough space for all of them in the new measuring room.

Not a breath of hot air

The air-conditioning in the measuring room sets new standards. A finely controlled climatisation system keeps the room temperature at a constant 22 degrees, the people in the room scarcely notice the air flow and the relative humidity is ideal. Factors that make the difference. The location of the measuring room is also perfect. It is next to the stores to reduce any vibrations that might have influenced measurement accuracy. Should any vibrations occur, the Leitz Reference Xi has an active damping system to deal with them.

The concept is based on a high-precision coordinate measuring machine and a high-tech measuring room. The metrology team at BSH Traunreut have now no problems keeping up with the technical advances in the kitchen.