Electronics manufacturing efficiency

Optimising use of materials and machine capacity gives electronic equipment manufacturers an important competitive edge

Contact us

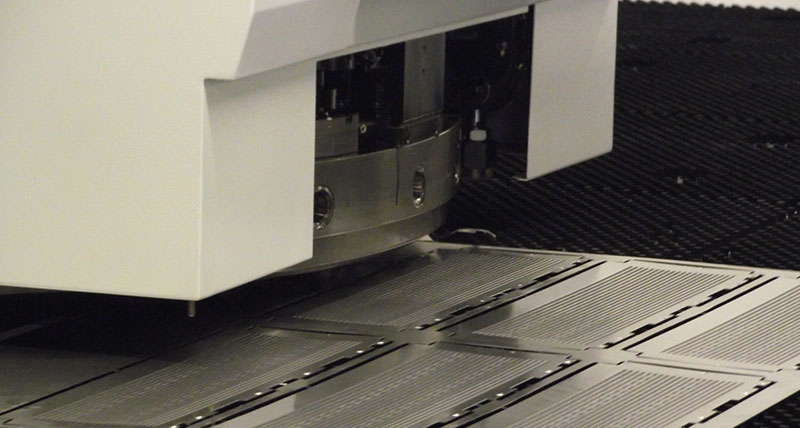

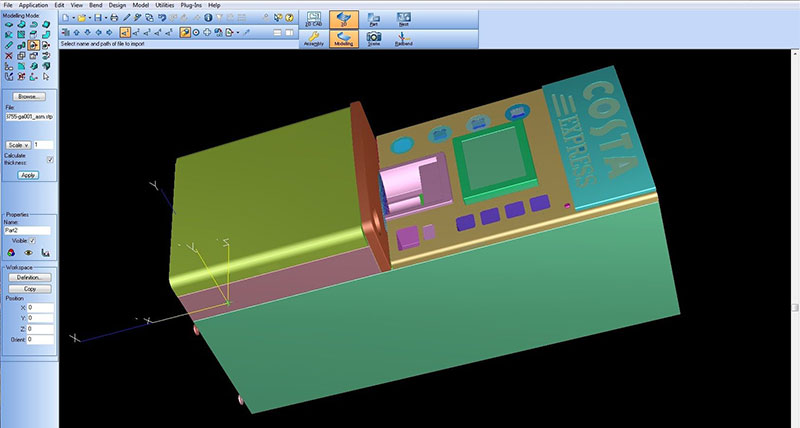

How efficiently an electronics company can produce and assemble parts and products has a decisive impact on its competitiveness and profitability. Whether it’s a question of assembling speakers, creating metal housings or plastic enclosures for PCs, tablets or smartphones, producing precision plastic injection moulds, or additive manufacturing, it’s crucial to optimise machine use and minimise any waste of materials. This means following designs to the letter and gaining full insight into production and assembly operations. Hexagon’s production software helps electronics companies capture design data and optimise the use of materials and machine capacity. Crucially, we enable our customers to better capture data and integrate it into a digital thread to improve design, engineering and quality control.

Use cases

See how Hexagon solutions are supporting electronics manufacturing efficiency

Scalable, versatile production of electronic device enclosures

Discover how to enhance electronic enclosure production efficiency

Reducing material waste generated by electronics batch production

Discover how to cut batch production costs and wastage