Engineering Analysis

Streamlined analysis and design enables your engineering teams to participate in a lean workflow.

Hexagon keeps pace with changes in international standards and codes, so you are always assured of up-to-date, internationally viable output. We closely monitor industry trends and new technologies to keep you on the leading edge of engineering analysis and design.

Engineering Disciplines

-

Structural

-

Mechanical

-

Pipe stress

Structural Analysis and Design

Structural engineers' first responsibility is to public safety, and next is to provide clients with cost-effective solutions. They are challenged to analyse structures of differing materials and geometry variations, and also to ensure their designs include multiple load combinations and meet local design codes.

Engineers have long understood the PC’s computational power for structural analysis, starting with simple spreadsheets through today’s specialised, fit-for-purpose software.

In a typical project, multiple siloed programs may be needed to perform analysis and design. Engineers may wonder if they can trust the results of black-box software and waste time trying to keep up with multiple software packages.

Hexagon’s solution is general-purpose, interoperable for a LEAN workflow, time-tested and known for reliable computation. It has an open interface and documented design code implementation, providing a single, trusted solution for solving even the most complex problems.

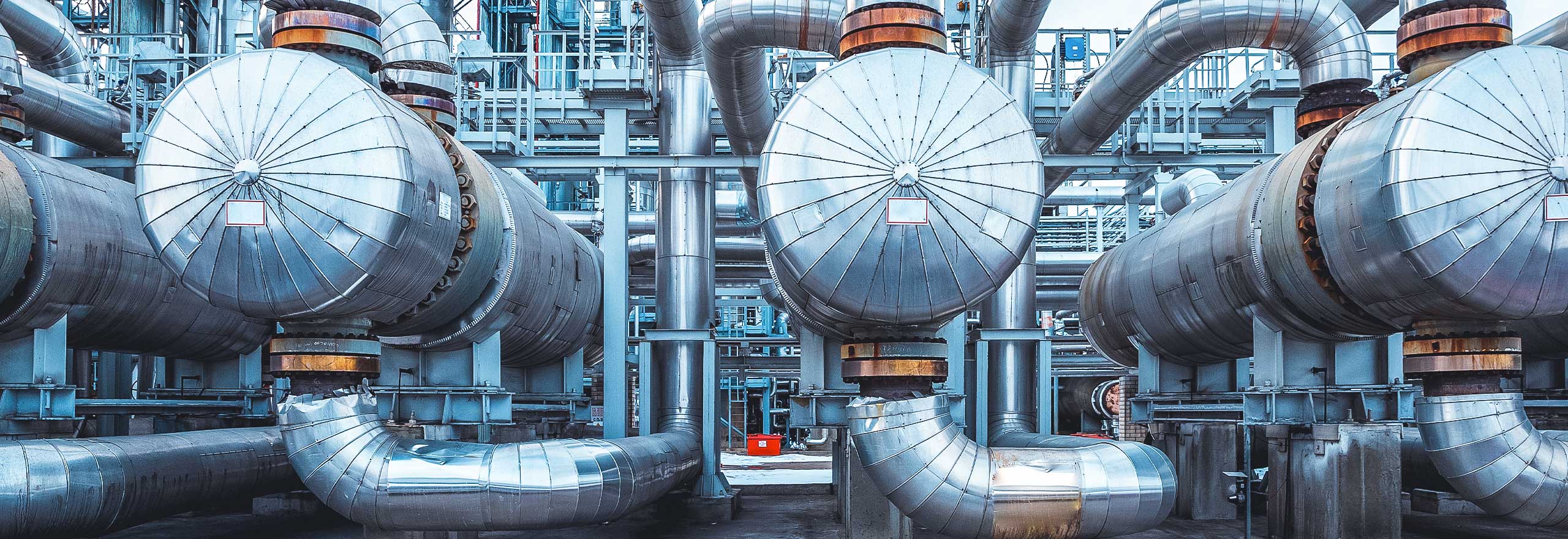

Static Equipment Analysis and Design

Pressure vessel or tank failure can be not only costly, but also very dangerous. That’s why it’s critical that equipment such as vessels, heat exchangers and storage tanks are designed accurately and meet code requirements, including the most commonly used pressure vessel design codes: ASME Section VIII Div. 1 & 2, PD 5500, and EN 13445.

Pressure vessels corrode over time, and engineers need to evaluate current state and remaining life of their equipment. Hexagon engineering analysis solutions help you confidently design equipment for the most extreme uses, such as radical temperature and pressure excursions.

Pipe Stress Analysis

For facility owners, the highest priority is the safety of people, installations, operations and the environment. Computer-aided engineering software helps prevent catastrophic events, such as explosions and leaks, with the ability to predict and control the behavior of piping systems due to certain applied loads.

Stress analysis is required for piping systems identified as critical due to the potential consequences of a system failure. It can be performed at different stages during the lifecycle of an asset. During the design phase, changes on piping systems may be recommended as a result of the stress analysis, which could trigger a cascade of changes for other project stakeholders that could compromise the schedule and budget of the project.

Types of engineering analysis performed by pipe stress engineers include:

• Static and dynamic analysis

• Offshore analysis

• Seismic analysis

• Fatigue analysis

• Equipment analysis

• Flange leak analysis

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

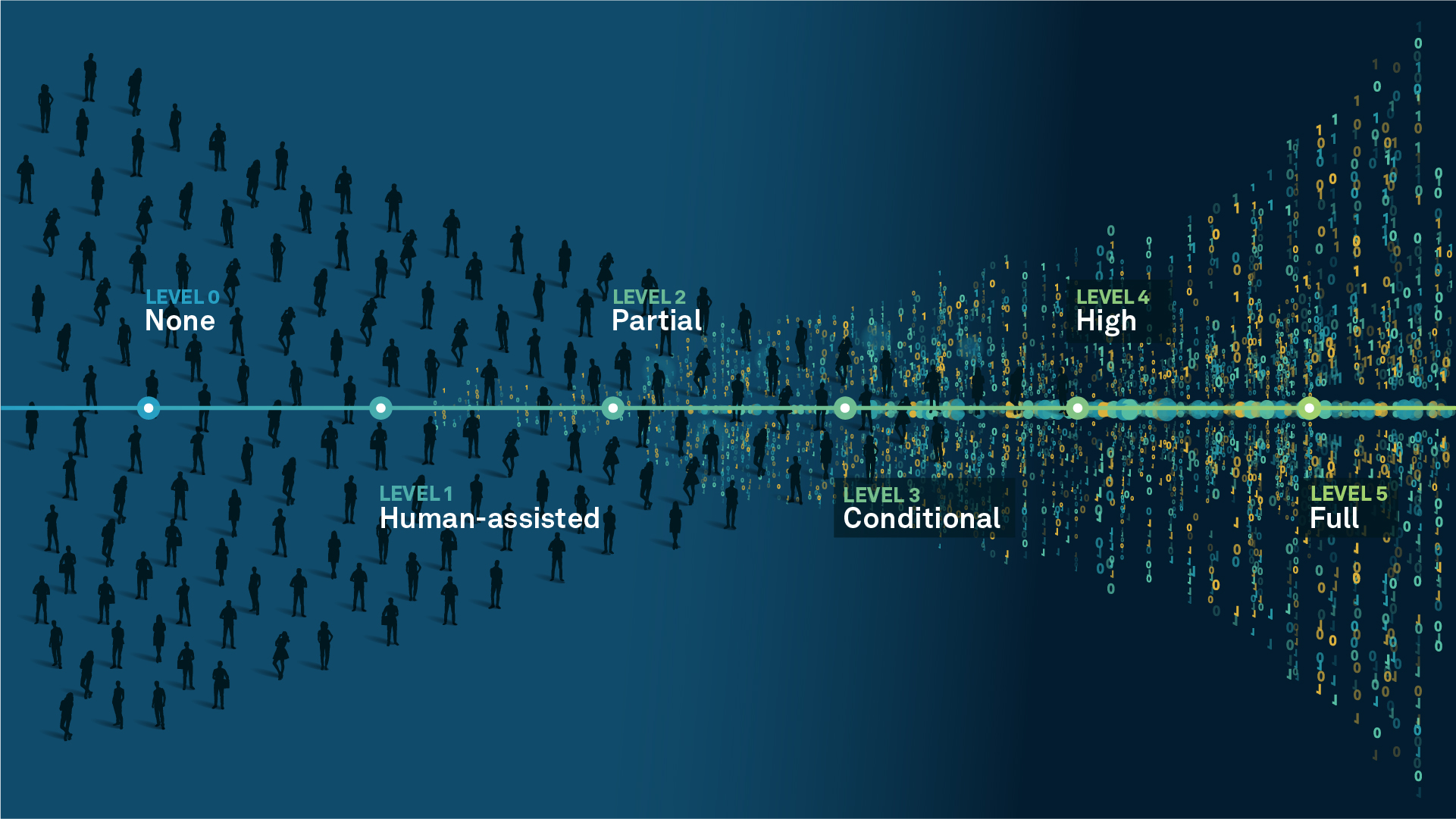

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.