Delivering top levels of Swiss accuracy

Leitz Infinity puts Gribi Messtechnik in the same league as national metrology institutes

Contact us

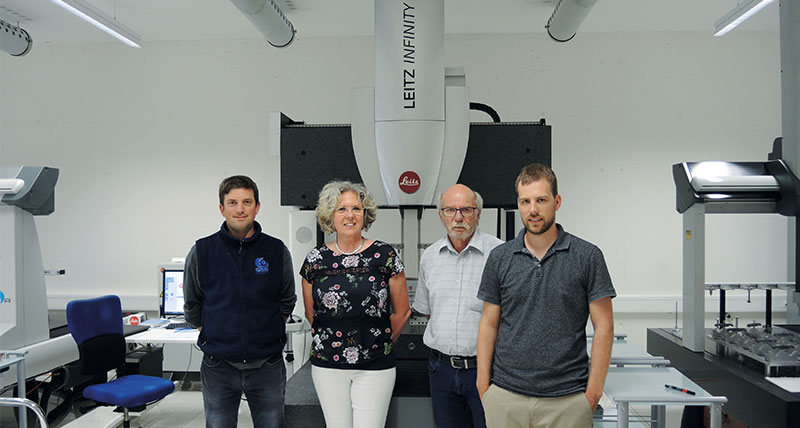

A measurement service provider in the small community of Büren an der Aare in the Swiss canton of Berne is pushing the boundaries of 3D metrology, helped by a Leitz Infinity coordinate measuring machine.

“We are never satisfied with the status quo; we always want more. Limits are there to be crossed,” explains Rudolf Gribi, Managing Director of Gribi Messtechnik AG. “We do this because we have many customers who only want the best and appreciate high precision because they can use it to optimise their products”.

Gribi Messtechnik has been offering independent and comprehensive services in the field of geometric metrology since it opened in Büren an der Aare in 2003. The company has two main pillars of expertise: 3D metrology and 3D calibration.

Gribi Messtechnik’s customers come from all over the world to have Gribi perform initial sample tests, single part or large series measurements - if required within a 24-hour operation - and to calibrate their test equipment. Many different industries rely on Gribi’s expertise, from companies in the medical technology and pharmaceutical space, through to those specialised in precision mechanics, automotive manufacturing, aerospace and mechanical engineering. Gribi Messtechnik also has expertise in gear and worm gear measurement, including gears from module 0.2.

“We have also made a name for ourselves on the international stage for delivering high-precision measurement results when market competitors have had to admit defeat,” says Gribi. “If necessary, we also look for new solutions for our customers’ metrological challenges.” In addition, the family-owned company is very flexible: some time ago, when a customer from Germany called Gribi’s mobile phone late on a Friday evening and told him about the urgency of an order, the head of the company returned to the measurement laboratory.

Accredited according to ISO/IEC 17025

Gribi Messtechnik is continuously investing in technology to remain a leading measurement service provider and accredited calibration laboratory both in Switzerland and on the international stage. In 2007, the company built a measurement laboratory in accordance with the VDI/ VDE 2627 standard in quality class 1 in Büren. In 2008 the Swiss Accreditation Service (SAS) gave it an ISO/IEC 17025 accreditation. This made Gribi Messtechnik one of the first accredited 3D testing laboratories in Switzerland to meet the strict requirements of the international standard for the performance of 3D testing. In 2011, the investment in a high-precision Leitz PMM coordinate measuring machine for calibrations was followed by accreditation as a calibration laboratory according to ISO/IEC 17025.

for the performance of 3D testing. In 2011, the investment in a high-precision Leitz PMM coordinate measuring machine for calibrations was followed by accreditation as a calibration laboratory according to ISO/IEC 17025.

But Gribi Messtechnik wanted to go further. “With five tactile measuring devices and a multisensor machine

as well as two CTs, we were able to meet almost all requirements in industrial metrology,” Gribi says. However, “the demands for accuracy have risen massively in recent years. This applies to high-precision components that we measure, but even more so to the safe and traceable calibration of test equipment. Therefore, we needed a

high-precision coordinate measuring machine.”

“I was and still am very satisfied with Leitz PMM, Leitz Reference and Leitz Infinity, especially since the QUINDOS software opens up all possibilities for us,” says Gribi. “Nevertheless, we were open to looking around the market to see which measuring instrument represented the absolute optimum. We didn’t want to compromise”. A comparison of high-precision coordinate measuring machines from several providers showed no machine could meet the company’s accuracy needs like the Leitz Infinity.

“On paper, another provider’s machine specified higher accuracy capabilities,” recalls Gribi.”But that was pure theory, as it turned out. Our comparison of all the parameters relevant to accuracy and the verification of accuracy showed that the Leitz Infinity specifications remained true in the field and was the superior machine.”

We have also made a name for ourselves on the international stage for delivering high-precision measurement results when market competitors have had to admit defeat

Highest precision for tactile and optical measurements

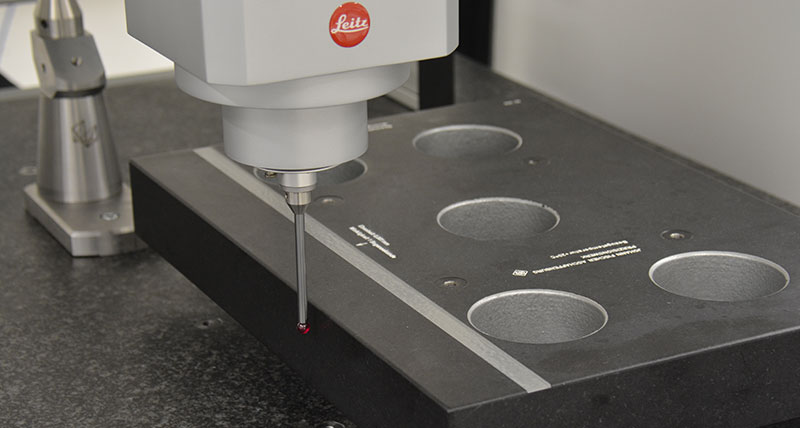

The closed-frame design of the Leitz Infinity, the high-resolution scales with a resolution of 1 nm and the specified basic accuracy of 0.3 μm - about 300 times smaller than the thickness of a human hair - form the basis of this superlative CMM.The Leitz Infinity is the most accurate coordinate measuring machine in its class and enables the combination of optical and tactile sensors in a single system. The measuring device is equipped as standard with the high-precision tactile high-speed scanning probe head LSP-S4.

In combination with the PRECITEC LR optical sensor, Leitz Infinity enables users to switch automatically between tactile and optical measuring technology within a measuring sequence. Gribi Messtechnik uses the optical sensor, for example, when measuring highly sensitive lenses made of glass or plastic that could be damaged by a probe.

In the same league as National Metrology Institutes

By opting for the Leitz Infinity, Gribi Messtechnik has catapulted itself into the same league as national metrology institutes when it comes to 3D metrology. “Among the metrology service providers in Switzerland, we are the only ones with this super-precise coordinate measuring machine,” says Gribi proudly.

In 2017, a new Leitz Infinity was delivered and installed at Gribi Messtechnik. It had a few months to acclimatise in the measuring room. Then a service technician from Hexagon came in and laser-corrected, calibrated and finally approved the device. “This service technician is still the Hexagon wizard for me today,” says Gribi with a laugh. “He worked with great concentration, checking the accuracy of the machine with gauge blocks to get the most out of the Leitz Infinity.”

Gribi Messtechnik then tested the Leitz Infinity. The first seven-hour test measurement of a component showed that the largest measurement deviation of the coordinate measuring machine at a temperature of 20 °C with a deviation of 0.09 °C over the entire measurement period was just 0.1 μm.

With the Leitz Infinity, Gribi Messtechnik has extended its 3D calibration capabilities into the sub-micrometer

range. With three coordinate measuring machines qualified for calibration - Leitz Reference HP, Leitz PMM and the new Leitz Infinity - the company now offers a wide range of services with two accuracy levels. “This allows our customers to choose between high-precision and standard calibrations with the optimum cost-benefit ratio,” says Gribi. “In addition, the Leitz Infinity naturally complements our portfolio of high-precision component measurement.”

Leitz Infinity enables sub-micron-level accuracy measurement of small features

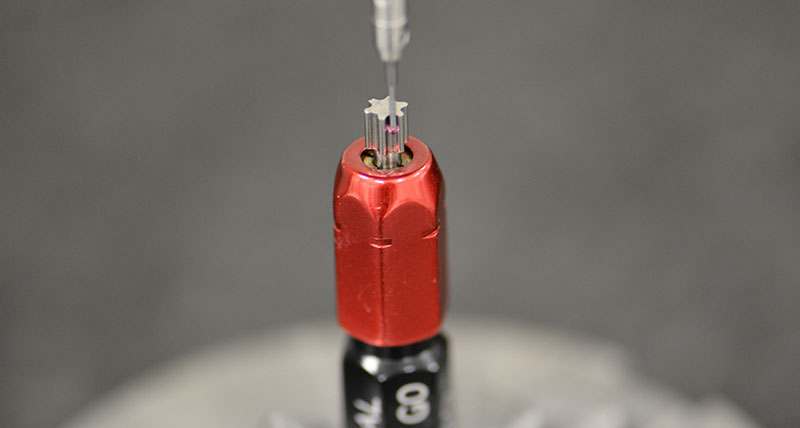

At Gribi Messtechnik, most of the work on the Leitz Infinity involves calibrating standards and artefacts, reference bodies and setting gauges with a volume of 1200 mm x 1000 mm x 600 mm. However, the company also uses the Leitz Infinity for measuring miniature parts, including tiny screw gauges for implants produced by a medical technology manufacturer. Standard probes cannot perform the task so Gribi and his team have developed a special tactile touch probe that allows them to measure foot radii of 0.02 mm without gaps. “Only with the Leitz Infinity are we able to measure these tiny thread profiles,” explains Gribi.

High precision is also in demand in the watch industry and Gribi Messtechnik measures watch plates with

the Leitz Infinity. “The industry has always spoken of precision in the micrometre range. But today it must also

be proven with measurement technology that tiny parts can be assembled automatically,” says Gribi. “Here the

requirements have increased enormously.”

The precision of the Leitz Infinity has even increased the efficiency of turbine blade mounts used in aviation. Due to the low measurement uncertainty offered by the measuring device, the manufacturer can now use the special grinding wheels much longer, thereby reducing the costs for expensive reworking or reconditioning. And the tolerances that Gribi Messetechnik calculated in the past can now be fully exploited. This means that the grinding wheels are in use much longer, and the costs for expensive reworking or reconditioning have been reduced. Gribi is pleased: “This is a very good example of the fact that with the Leitz Infinity we are also helping our customers to move the boundaries further back.